Cell divided ice storage tank

An ice storage tank and fractal technology, applied in space heating and ventilation, heating methods, lighting and heating equipment, etc., can solve problems such as large temperature gradient, low thermal conductivity, and increased energy loss in the process of cold storage and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing for further description:

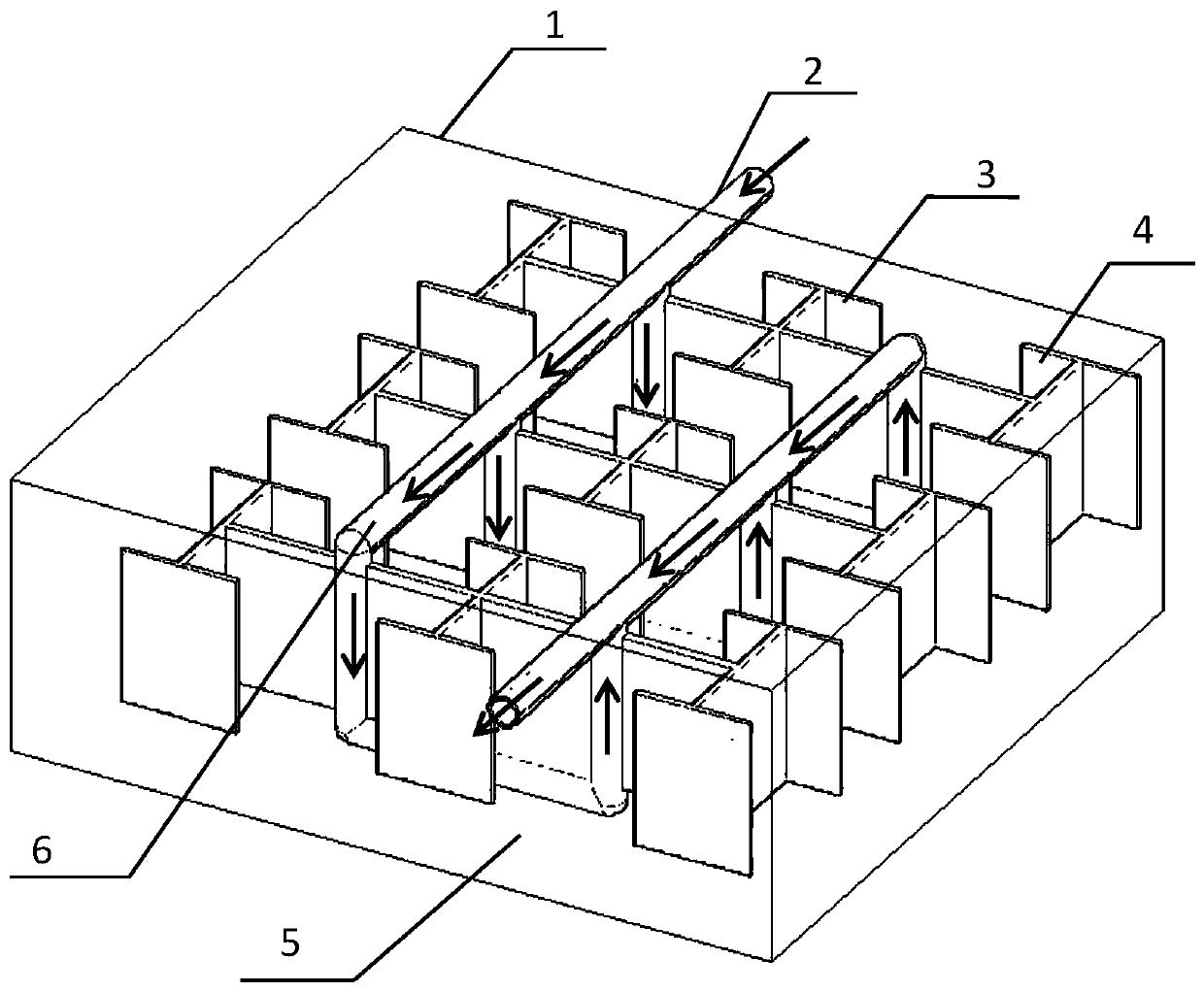

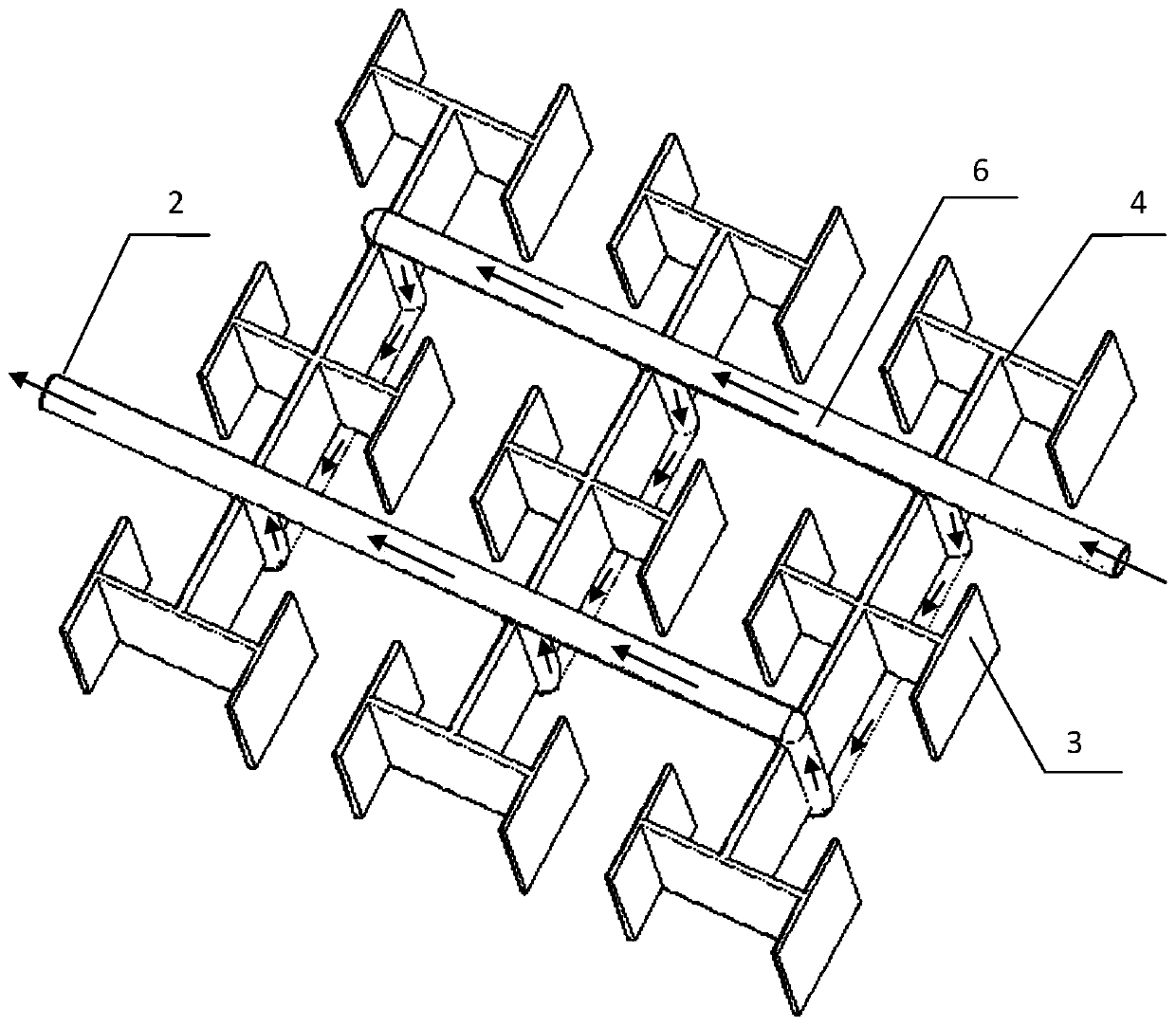

[0027] figure 1 An overall schematic diagram of the compartment fractal ice storage tank of the present invention is given. It is composed of tank body 1, coil pipe 2, thermal diffusion plates 3 and 4, cold storage medium 5 and brine 6. In order to reduce the loss of cooling capacity, the wall surface of the tank body 1 is sandwiched with thermal insulation material and wrapped with thick polystyrene boards. The coil tube 2 is arranged in the tank body 1, and the coil tube at the inlet and outlet extends out of the tank body, so that the brine 6 flows in from one end and flows out from the other end. The thermal diffusion plates 3 and 4 are arranged on the vertical coil tube, and the cold storage medium 5 placed in the tank. In order to facilitate observation and understanding, figure 2 A three-dimensional diagram of the internal structure of the ice storage tank is given.

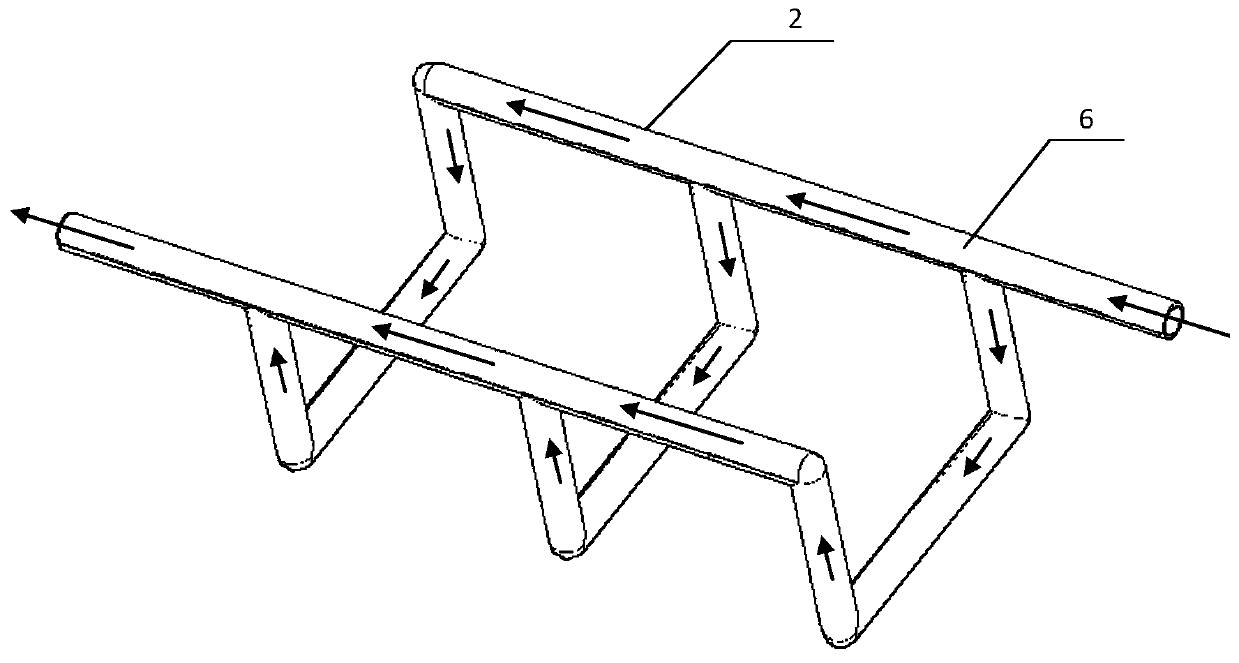

[0028] image 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com