Method and system for detecting mass flow rate of particles in pneumatic conveying process

A particle mass and pneumatic conveying technology, applied in mass flow measurement devices, indirect mass flow meters, measurement flow/mass flow, etc., can solve problems such as large measurement errors, improve performance, improve measurement accuracy, and improve spatial resolution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

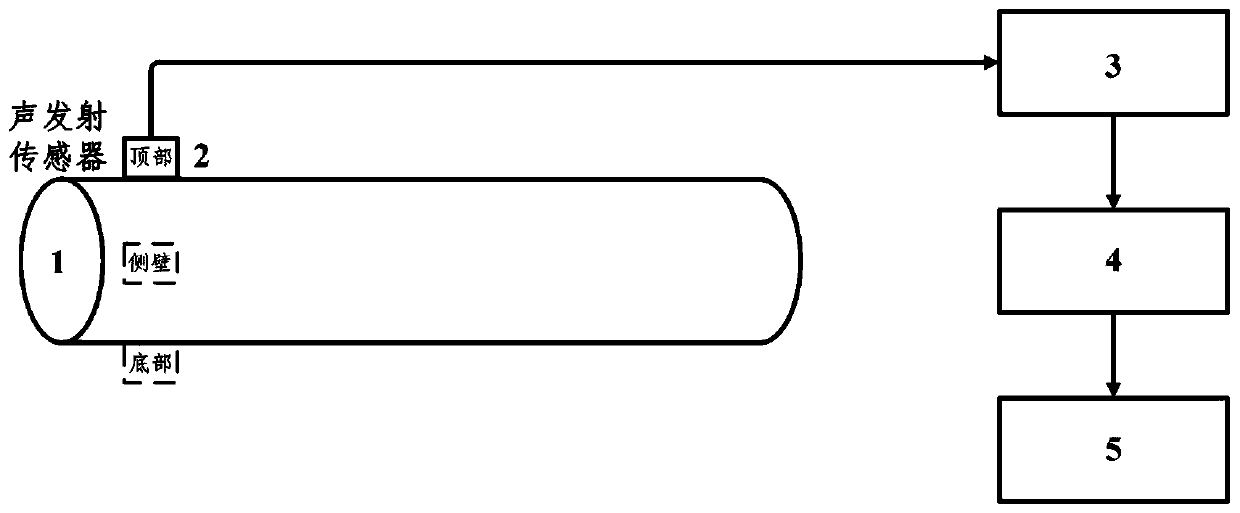

[0057] like figure 1 As shown, the detection device in this embodiment includes a horizontal material conveying pipeline 1, a group of acoustic wave sensors 2, a signal amplification device 3, a signal acquisition device 4, and a signal processing device 5; The sensor group 2 is connected with the signal amplifying device 3 to convert the acoustic wave signal into an electrical signal and transmit it to the signal amplifying device 3. The signal amplifying device 3 is connected with the signal collecting device 4 to transmit the amplified signal to the signal collecting device 4. The signal collecting device 4 and The signal processing device 5 is connected to analyze the collected signal.

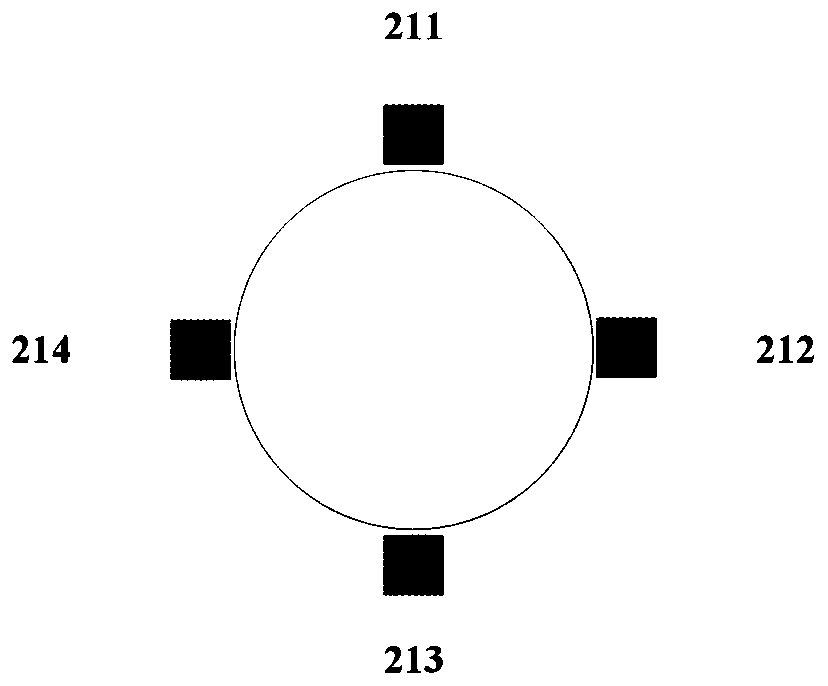

[0058] like figure 2 As shown, in this embodiment, the acoustic wave sensor group 2 includes four acoustic wave sensors, and the four acoustic wave sensors are respectively 211, 212, 213 and 214, which are evenly distributed along the same circular section of the pipeline 1, and the incl...

Embodiment 2

[0065] like figure 1 As shown, the detection device in this embodiment includes a horizontal material conveying pipeline 1, a group of acoustic wave sensors 2, a signal amplification device 3, a signal acquisition device 4, and a signal processing device 5; The sensor group 2 is connected with the signal amplifying device 3 to convert the acoustic wave signal into an electrical signal and transmit it to the signal amplifying device 3. The signal amplifying device 3 is connected with the signal collecting device 4 to transmit the amplified signal to the signal collecting device 4. The signal collecting device 4 and The signal processing device 5 is connected to analyze the collected signal.

[0066] like figure 2As shown, in this embodiment, the acoustic wave sensor group 2 includes four acoustic wave sensors, the four acoustic wave sensors are respectively 211, 212, 213 and 214, which are evenly distributed along the same circular section of the pipeline 1, and the included ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com