A thermal battery single cell testing device and testing method

A single battery and testing device technology, which is applied in the field of thermal battery single battery testing devices, can solve problems such as uncontrollable pressure, easy damage to the furnace plate, and difficult operation, so as to ensure stability, simplify assembly and test difficulty, Guaranteed consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 A thermal battery cell testing device

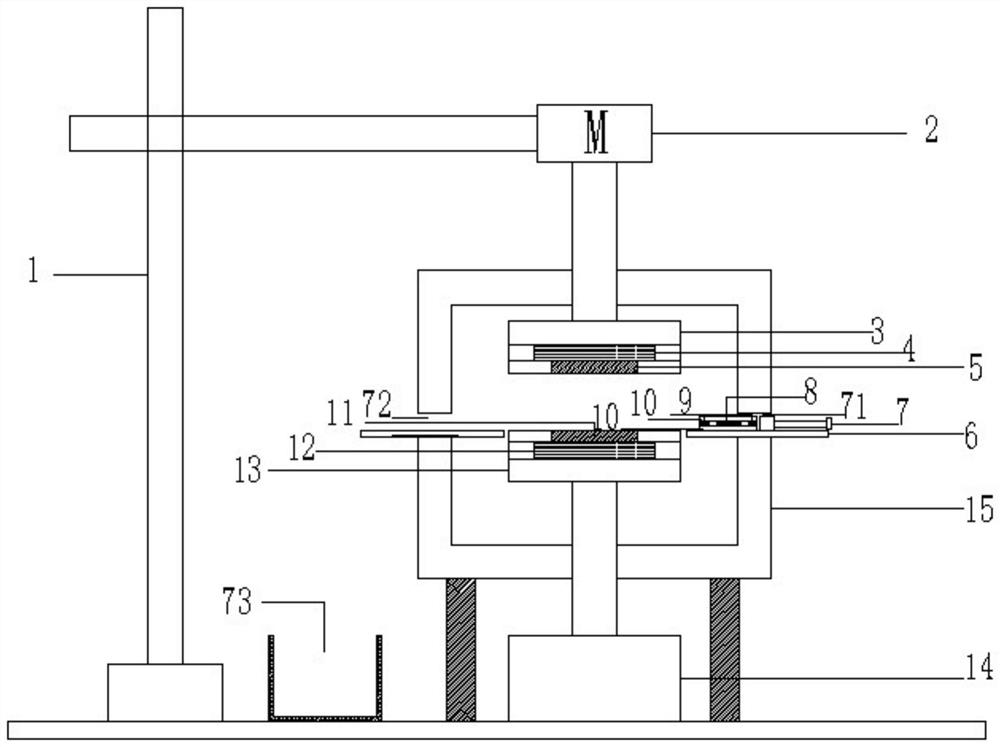

[0043] The device includes a single battery assembly system and a single battery electrical performance testing system, figure 1 Assemble the system for the single cell.

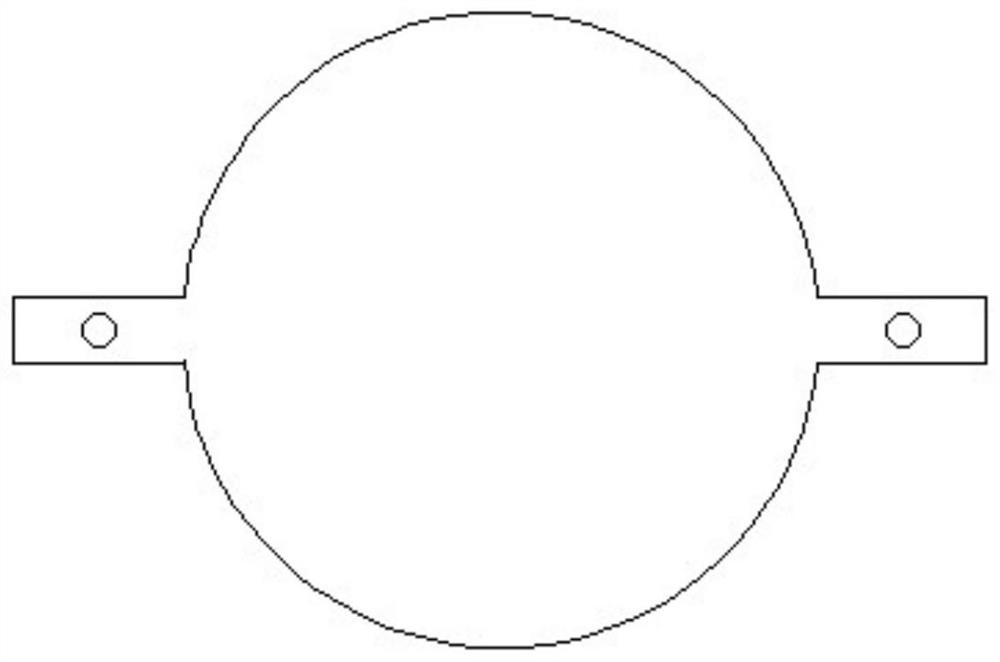

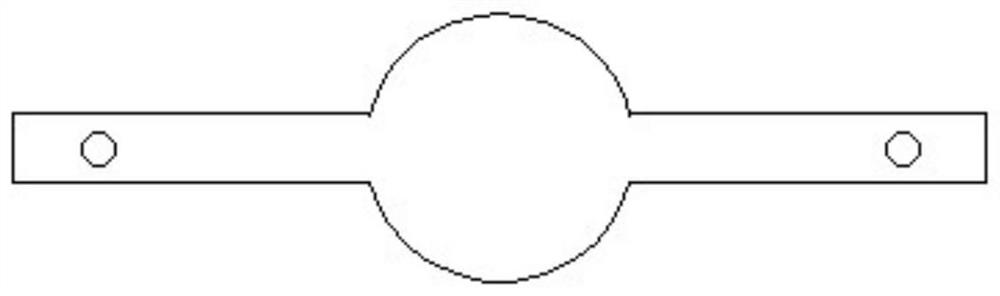

[0044] combine Figure 2-5 , it can be seen that the single battery assembly system includes a first stainless steel bracket 1, a motor 2, an upper pressure plate 3, an upper insulating sheet 4, and an upper current collecting sheet 5. The upper current collecting sheet 5, the upper insulating sheet The sheet 4 and the upper pressure plate 3 are a whole, and the upper pressure plate 3 is connected to the motor 2 through the top opening of the heating furnace 15 and is fixed on the first stainless steel bracket 1;

[0045] It also includes a second stainless steel bracket 6, a material pushing device 7, a single battery 8, an anti-overflow ring 9, a stainless steel sheet 10, a lower collector sheet 11, a lower insulating sheet 12, a lower pressure pla...

Embodiment 2

[0051] Example 2 A thermal battery cell testing device

[0052] In the thermal battery single cell testing device, the anti-overflow ring 9 is a perforated asbestos sheet or a mica sheet, and the bottom is fixed on the stainless steel sheet 10 . During the test, the single battery 8 is assembled into the inner hole of the anti-overflow ring 9 , and then the stainless steel sheet 10 is fixed on the top of the anti-overflow ring 9 .

[0053] In the thermal battery single cell testing device, the inner diameter of the anti-overflow ring 9 is larger than the diameter of the single cell 8, the outer diameter of the anti-overflow ring 9 matches the diameter of the stainless steel sheet 10, and the thickness of the anti-overflow ring 9 It matches the thickness of the unit cell 6 .

[0054] Specifically, the inner diameter of the overflow prevention ring 9 is 35 mm, the outer diameter is 45 mm, and the thickness is 0.8 mm, and the diameter of the stainless steel sheet 10 is 45 mm.

...

Embodiment 3

[0057] Example 3 Single battery

[0058] The single battery 8 in the present invention is formed by pressing the negative electrode material, the diaphragm material and the positive electrode material under the pressure of 3t-10t, and the negative electrode material is lithium boron alloy, lithium silicon alloy or lithium aluminum alloy; the diaphragm The material is a mixture of ternary all-lithium electrolyte LiF-LiCl-LiBr and MgO, and the cathode material is FeS 2 or CoS 2 , ternary all-lithium electrolyte LiF-LiCl-LiBr and Li 2 A mixture of O. The single cell 8 has a diameter of 32 mm and a thickness of 0.8 mm.

[0059] The preparation of the single cell 8 includes:

[0060] (1) Negative electrode material: the negative electrode material is preferably a lithium boron alloy;

[0061] (2) Diaphragm material: The diaphragm material is a mixture of ternary all-lithium electrolyte LiF-LiCl-LiBr and MgO, which is composed of 5% LiF, 10% LiCl, 35% LiBr and 50% MgO.

[0062...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com