Electronic control of automated assembly machine in production of printed circuit boards

A technology for printed circuit boards and assembly machines, applied in program control, comprehensive factory control, general control systems, etc., can solve problems such as inappropriateness and affect the production process, and achieve local resources, cost savings, and good line load utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

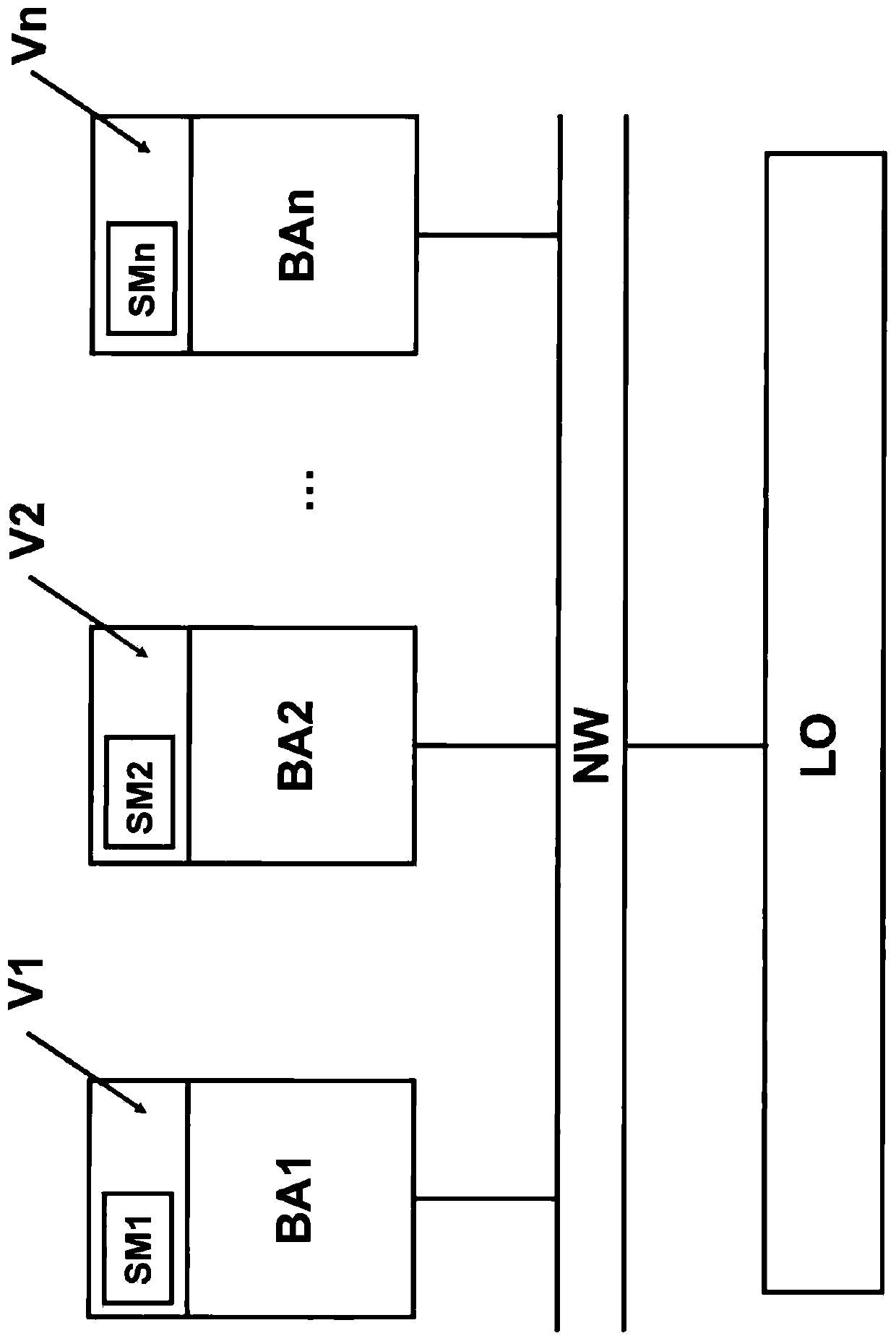

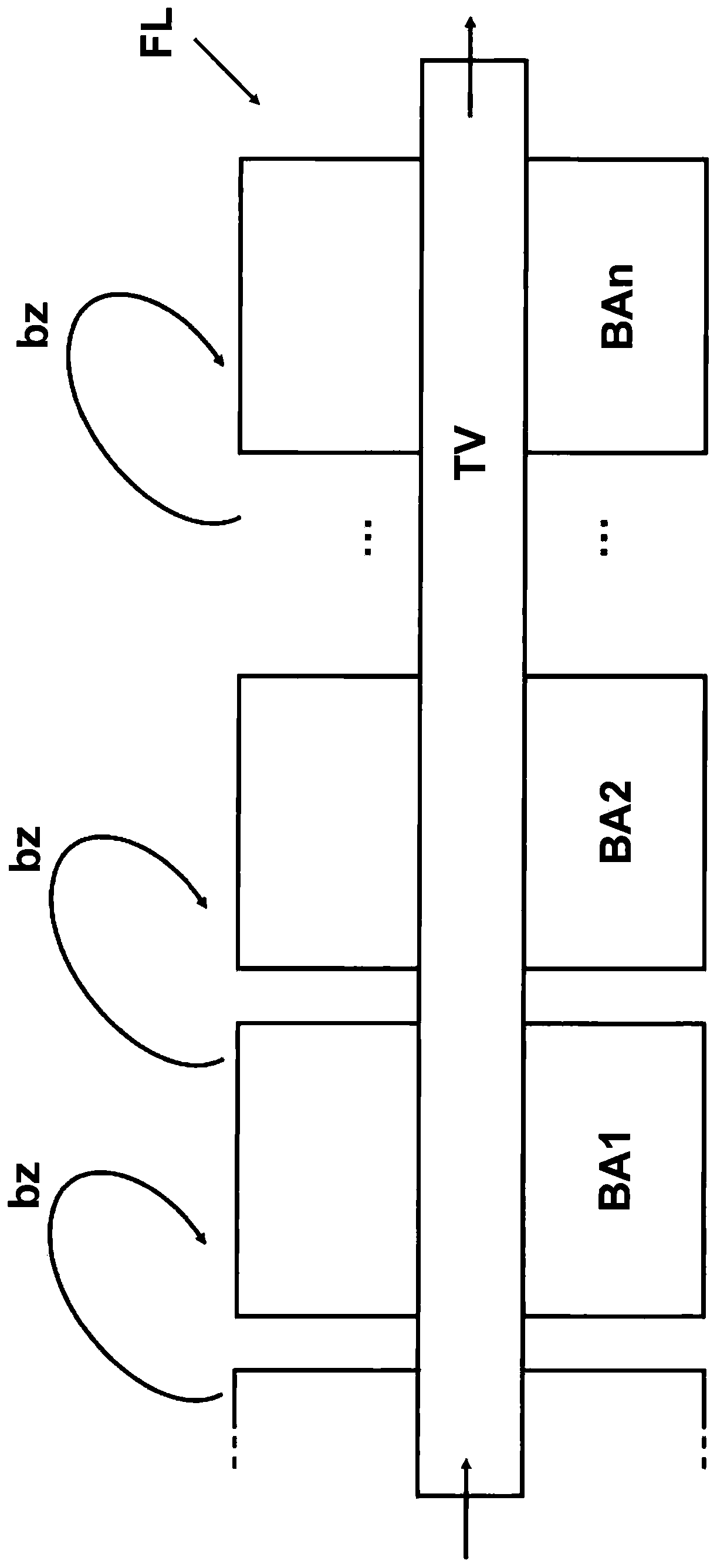

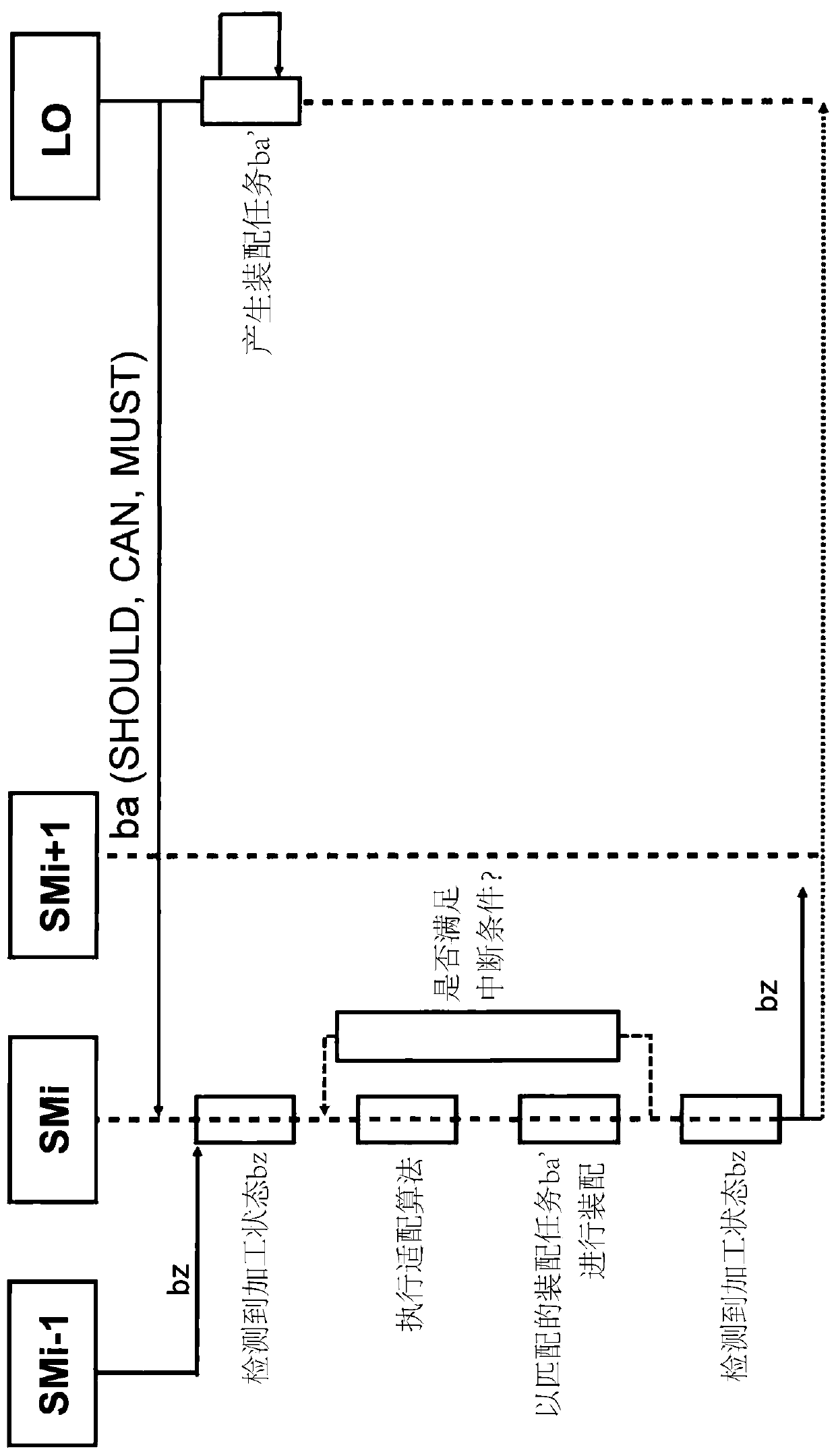

[0099] The invention serves for the local adaptation of centrally generated assembly tasks and is described below using the example of printed circuit board production. However, the invention can also be transferred to other components to be assembled.

[0100] The strict assignment of assembly tasks to assembly machines is relaxed. There are two types here:

[0101] 1. More assembly (DO MORE command)

[0102] When machine A completes its assembly procedure (synonymous with assembly task), but subsequent machine B has not yet signaled its readiness (due to a temporary failure, for example), machine A takes over for all subsequent machines C / D / … and A partial assembly program for the failed machine B, if components assembled in machine A are available for this. Information about the further assembly is transmitted to subsequent machines by means of the processing status (data indicating that additional assembly positions have been occupied). A network connection can be used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com