A continuous washing machine for waste plastic fragments

A technology for plastic fragments and waste plastics, which is applied in the field of continuous washing machines for waste plastic fragments to achieve the effect of convenient cleaning and replacement and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

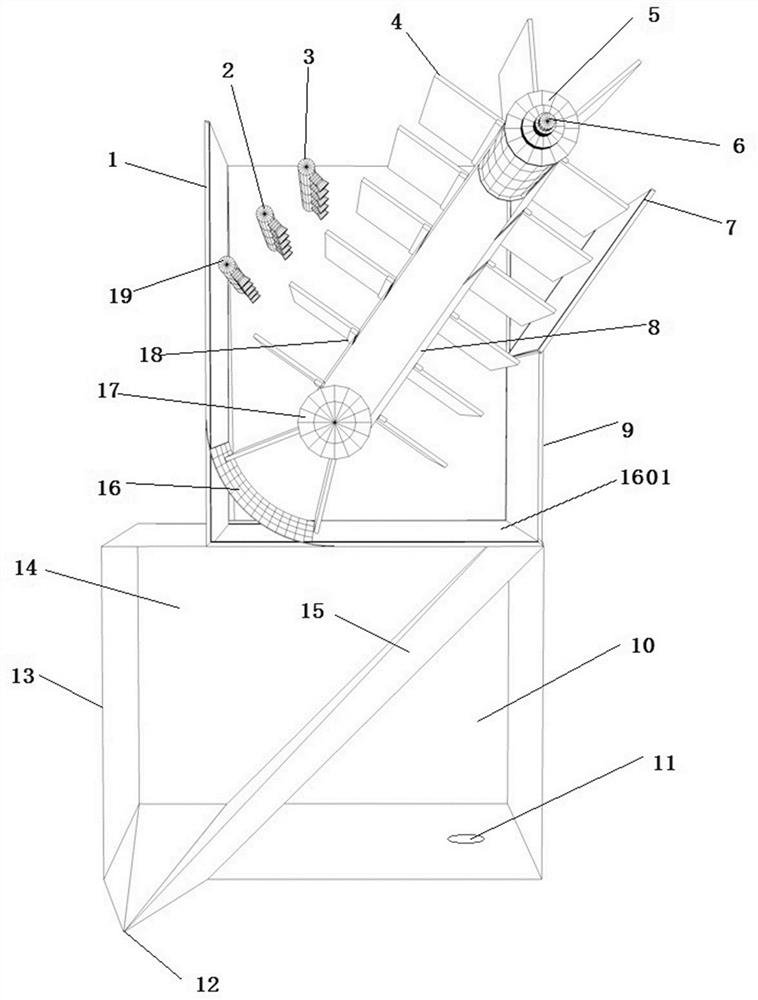

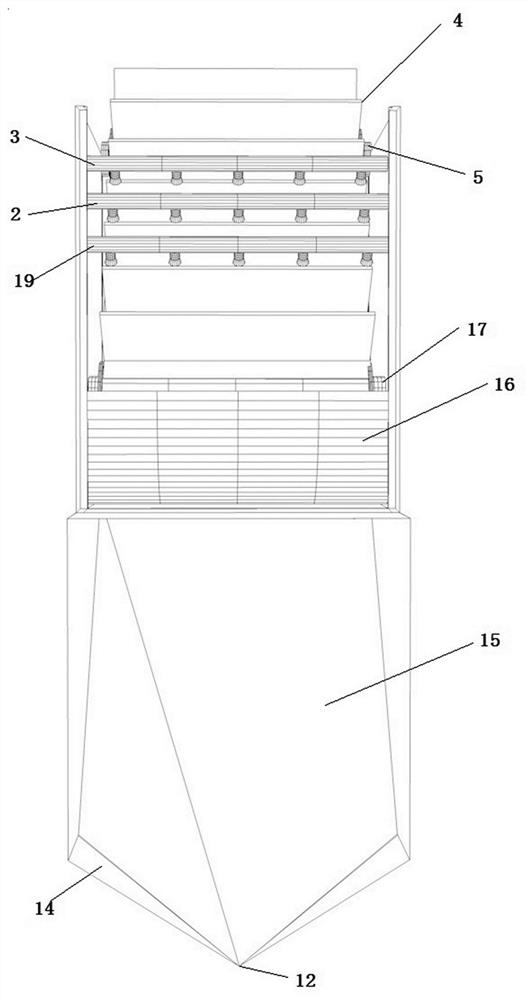

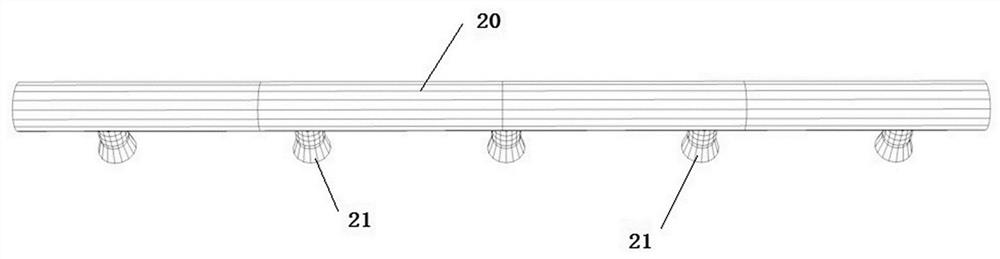

[0030]A continuous washing machine for waste plastic fragments, the structure of which is as follows Figure 1-Figure 5 As shown, it includes the main body 1, and also includes a waste plastic fragment conveying system that is arranged inside the main body 1 and cooperates with the main body 1. One side of the waste plastic fragment conveying system is provided with a high-pressure water spraying system, and the bottom end of the waste plastic fragment conveying system is provided with There is a water receiving and processing system; the waste plastic debris conveying system includes a driving shaft 5 arranged at the upper end of the main body 1 and a driven shaft 17 arranged at the lower end of the main body 1; a speed-regulating motor is arranged on the driving shaft 5, and the driving shaft 5 passes through The conveyor belt 8 is connected with the driven shaft 17, and the conveyor belt 8 is provided with a plurality of uniformly arranged plastic debris scrapers 4, and one ...

Embodiment 2

[0035] A continuous washing machine for waste plastic fragments, the structure of which is as follows Image 6 As shown, the difference from Embodiment 1 is that: a camber plate 1602 is provided on the top where the adapter plate 16 meets one side of the main body 1; by setting the camber plate 1602, the side of the main body 1 There is a large gap between the nozzle groups 19, 2, and 3, which facilitates the waste plastic fragments to fall to the adapter plate 16 through the gap, and reduces the waste plastic fragments to fall to the conveyor belt 8 through the gap between the nozzle groups 19, 2, and 3 It is possible to prevent waste plastic fragments from falling into the next process without repeated cleaning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com