U-shaped heat exchange pipe and pipe plate welding process and application thereof

A technology for tube-sheet welding and heat-exchanging tubes, applied in welding equipment, welding accessories, manufacturing tools, etc., can solve problems such as idle waste of equipment, gap corrosion, and reduction of material tensile strength, so as to reduce production costs and overcome tube spacing Small, the effect of ensuring the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

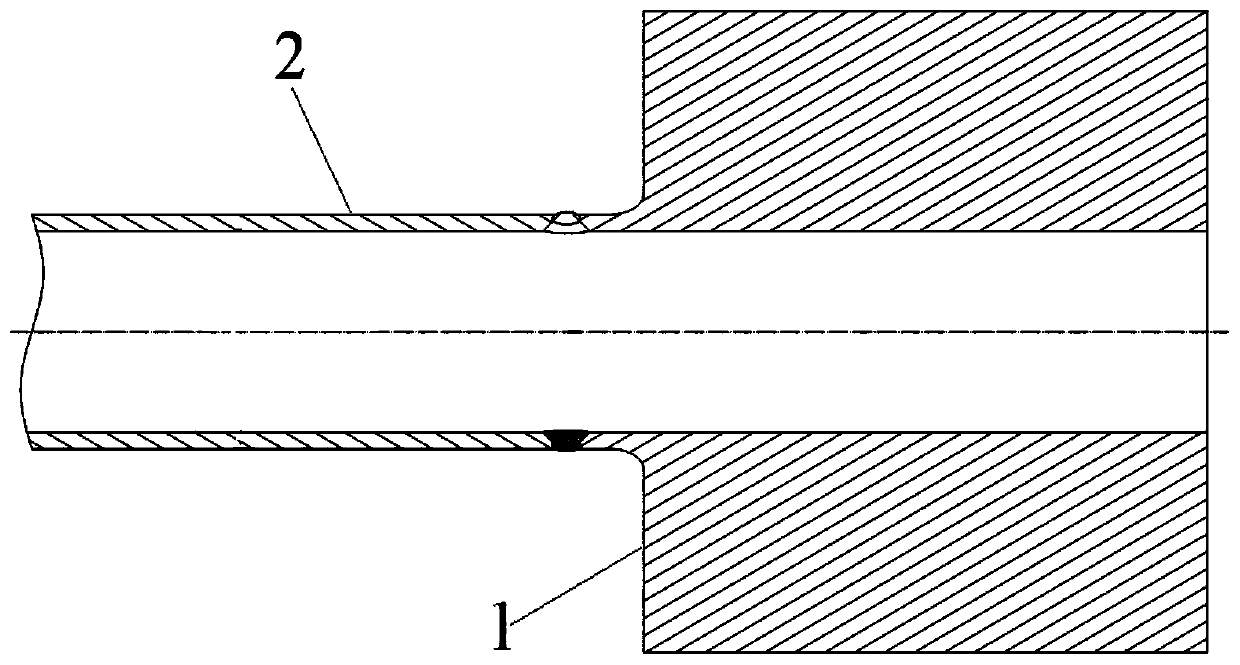

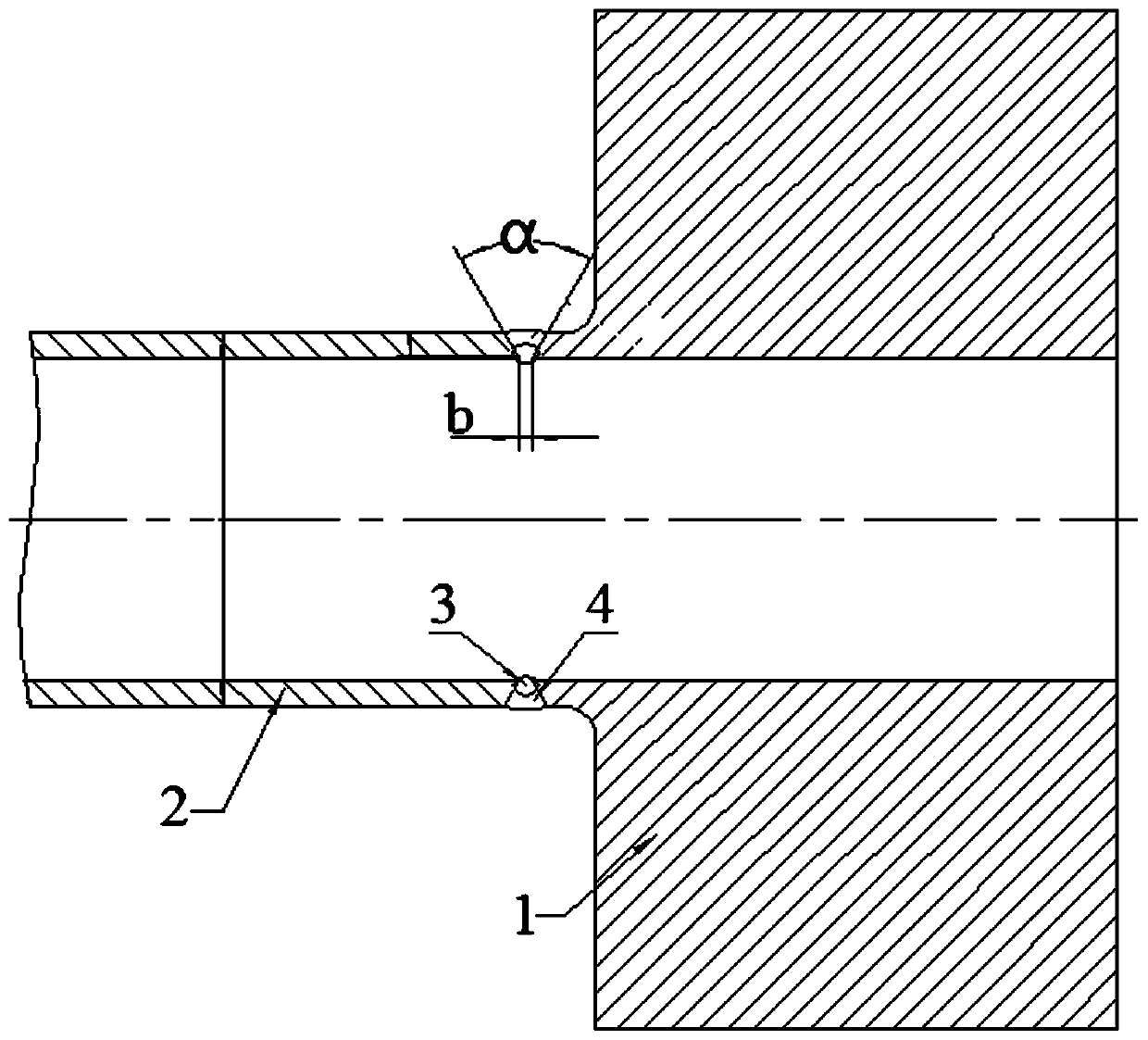

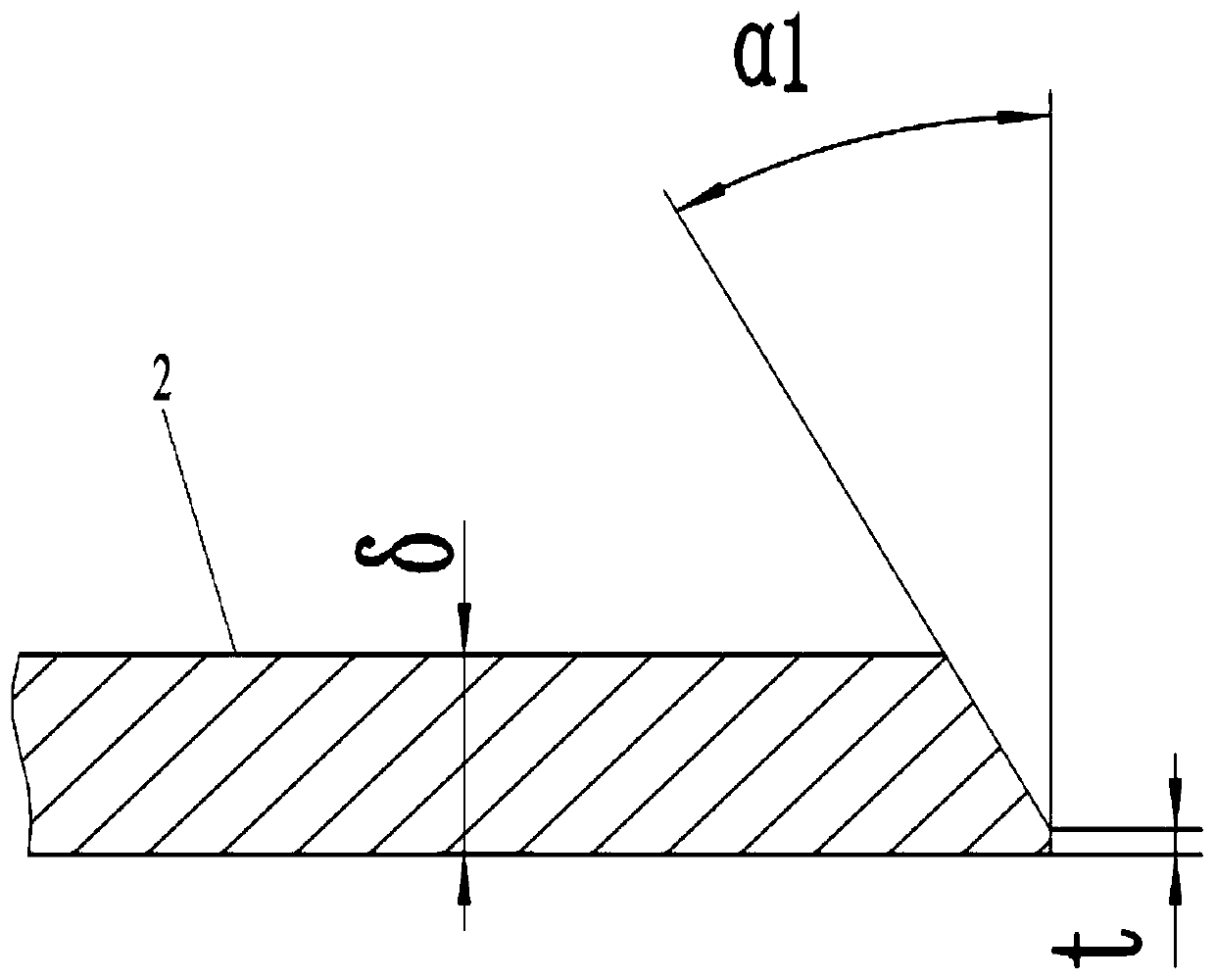

[0041] first embodiment , a U-shaped heat exchange tube and tube sheet welding process, refer to Figure 2-4 , the material of the tube sheet is 16MnⅢ forging, the thickness δ is 90mm, the material of the heat exchange tube is Q345D, and the specification is φ57×4mm, and the welding process includes the following steps:

[0042] (1) Thoroughly clean the rust and other impurities and dirt within 20mm of the welding end of the tube sheet 1 and heat exchange tube 2;

[0043] (2) Use a portable pipe beveling machine to process the convex edge of the welding hole on the tube sheet 1 and the welding end of the heat exchange tube 2 into a bevel. The mouth angle α1 is 28°.

[0044] (3) After the groove is processed, use a grinder to thoroughly clean the rust, burrs and other impurities and dirt within 20mm on both sides of the groove.

[0045] (4) After the cleaning is completed, the traditional method of threading the heat exchange tubes in columns is changed to threading the tub...

no. 2 example

[0051] second embodiment , a U-shaped heat exchange tube and tube sheet welding process, refer to Figure 2-4 , the material of the tube sheet is 16MnⅢ forging, the thickness δ is 90mm, the material of the heat exchange tube is Q345D, and the specification is φ57×4mm, and the welding process includes the following steps:

[0052] (1) Thoroughly clean the rust and other impurities and dirt within 20mm of the welding end of the tube sheet 1 and heat exchange tube 2;

[0053] (2) Use a portable pipe beveling machine to process the convex edge of the welding hole on the tube sheet 1 and the welding end of the heat exchange tube 2 into a bevel. Groove angle α1 is 25°.

[0054] (3) After the groove is processed, use a grinder to thoroughly clean the rust, burrs and other impurities and dirt within 20mm on both sides of the groove.

[0055] (4) After the cleaning is completed, the traditional method of threading the heat exchange tubes in columns is changed to threading the tubes...

no. 3 example

[0061] third embodiment , a U-shaped heat exchange tube and tube sheet welding process, refer to Figure 2-4 , the material of the tube sheet is 16MnⅢ forging, the thickness δ is 90mm, the material of the heat exchange tube is Q345D, and the specification is φ57×4mm, and the welding process includes the following steps:

[0062] (1) Thoroughly clean the rust and other impurities and dirt within 20mm of the welding end of the tube sheet 1 and heat exchange tube 2;

[0063] (2) Use a portable pipe beveling machine to process the convex edge of the welding hole on the tube sheet 1 and the welding end of the heat exchange tube 2 into a bevel. The mouth angle α1 is 30°.

[0064] (3) After the groove is processed, use a grinder to thoroughly clean the rust, burrs and other impurities and dirt within 20mm on both sides of the groove.

[0065] (4) After the cleaning is completed, the traditional method of threading the heat exchange tubes in columns is changed to threading in rows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com