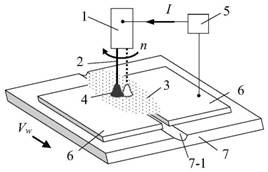

A rotary submerged arc high-speed welding method for thin plates

A welding method and submerged arc welding technology, applied in welding equipment, arc welding equipment, welding/welding/cutting articles, etc., can solve the problems of high deposition efficiency of submerged arc welding, complicated welding method implementation, and expensive welding equipment, etc. Achieve significant economic superiority, easy engineering promotion, and prevent weld penetration defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

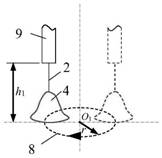

Method used

Image

Examples

Embodiment 1

[0046] Figure 8 Shown are the front and back weld formation photos of two thin plates 6 to be welded with a plate thickness δ of 2mm after high-speed rotary submerged arc butt welding. in, Figure 8 (a) and Figure 8 (b) are the assembly gap G 1 1mm, misalignment amount C 1 The front and back welding seam forming photos when it is 0.5mm, the width G of the forming groove 7-1 of the copper backing plate 7 used at this time 2 3mm, depth h 2 The set welding current I is 370A, the arc voltage is 35V, the arc rotation speed n is 4500r / min, the arc rotation radius r is 2mm, and the welding speed V w It is 2300mm / min. Figure 8 (c) and Figure 8 (d) are the assembly gap G 1 0mm, misalignment amount C 1 The front and back welding seam forming photos when it is 0.2mm, the width G of the forming groove 7-1 of the copper backing plate 7 used at this time 2 4mm, depth h 2 The set welding current I is 440A, the arc voltage is 36V, the arc rotation speed n is 6000r / min, the arc ...

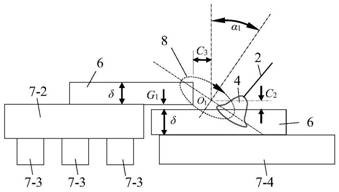

Embodiment 2

[0049] Such as Figure 4 As shown, the two thin plates 6 to be welded with the thickness δ of 3mm and 4mm are assembled into a lap groove form, and the assembly gap G 1 It is 0.5mm. Before welding, use a welding pressure plate to press the two thin plates 6 to be welded to be welded on the lifting backing plate 7-2 and the steel fixed backing plate 7-4 respectively. On the lifting backing plate 7-2 There are nine lifting platforms 7-3 evenly placed in three rows along the welding direction below. Before welding, adjust the torch inclination α of the rotary submerged arc welding torch 1 above the lap joint 1 30°, upper offset distance C 2 0mm, right offset distance C 3 is 0mm, the set welding current I is 350A, the arc voltage is 32V, the arc rotation speed n is 3000r / min, the arc rotation radius r is 2mm, and the welding speed V w It is 3000mm / min. After high-speed rotary submerged arc welding, a thin plate lap joint with good shape and meeting the requirements of use is ...

Embodiment 3

[0051] Such as Figure 5 As shown, the two thin plates 6 to be welded with a thickness δ of 5mm are assembled into a fillet groove form, and the assembly gap G 1 Before welding, use a welding pressure plate to press the two thin plates 6 to be welded on the copper backing plate respectively, and the four corners are respectively set with a width G along the welding direction. 2 3mm, depth h 2 1.5mm forming groove 7-1. Before welding, adjust the torch inclination α of the rotary submerged arc welding torch 1 above the fillet joint groove 1 60°, upper offset distance C 2 2.5mm, right offset distance C 3 The set welding current I is 500A, the arc voltage is 38V, the arc rotation speed n is 7200r / min, the arc rotation radius r is 4mm, and the welding speed V w It is 1000mm / min. After high-speed rotary submerged arc welding, a well-formed thin-plate fillet joint that meets the requirements of use is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com