A kind of combustion chamber thermal insulation layer vacuum patch automatic control system and operation method

A technology of automatic control system and heat insulation layer, which can be applied to household appliances, other household appliances, household components, etc., and can solve the problems of low automation and backwardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

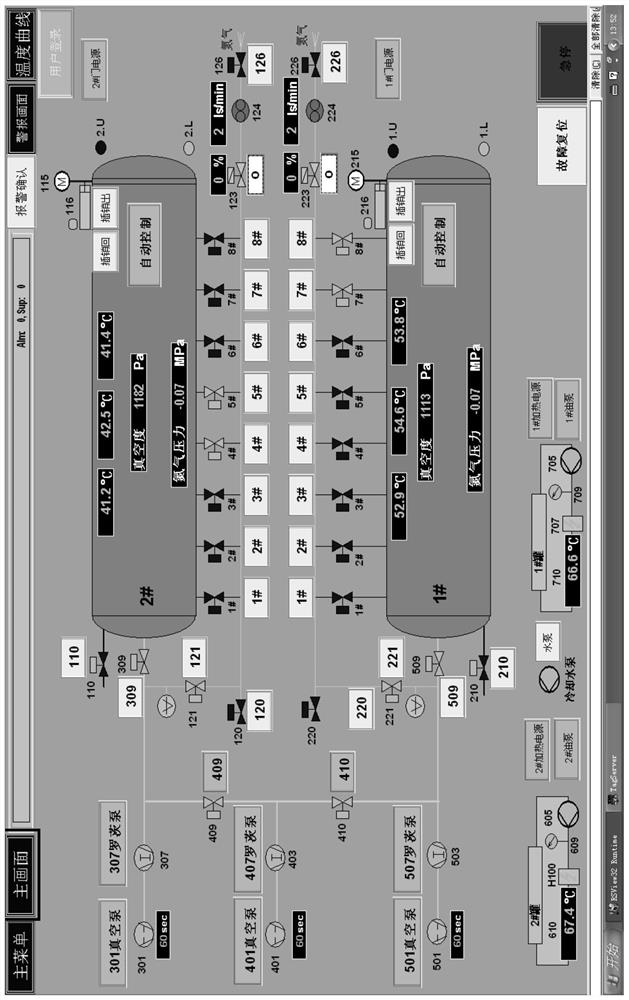

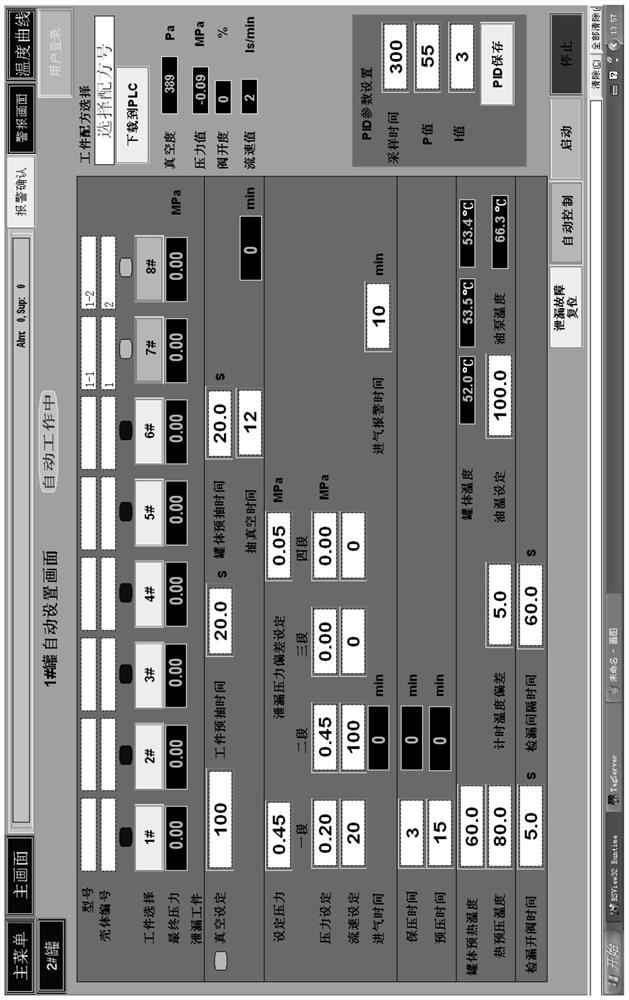

[0036] In order to make the above objects, features and advantages of the present invention more clearly understood, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

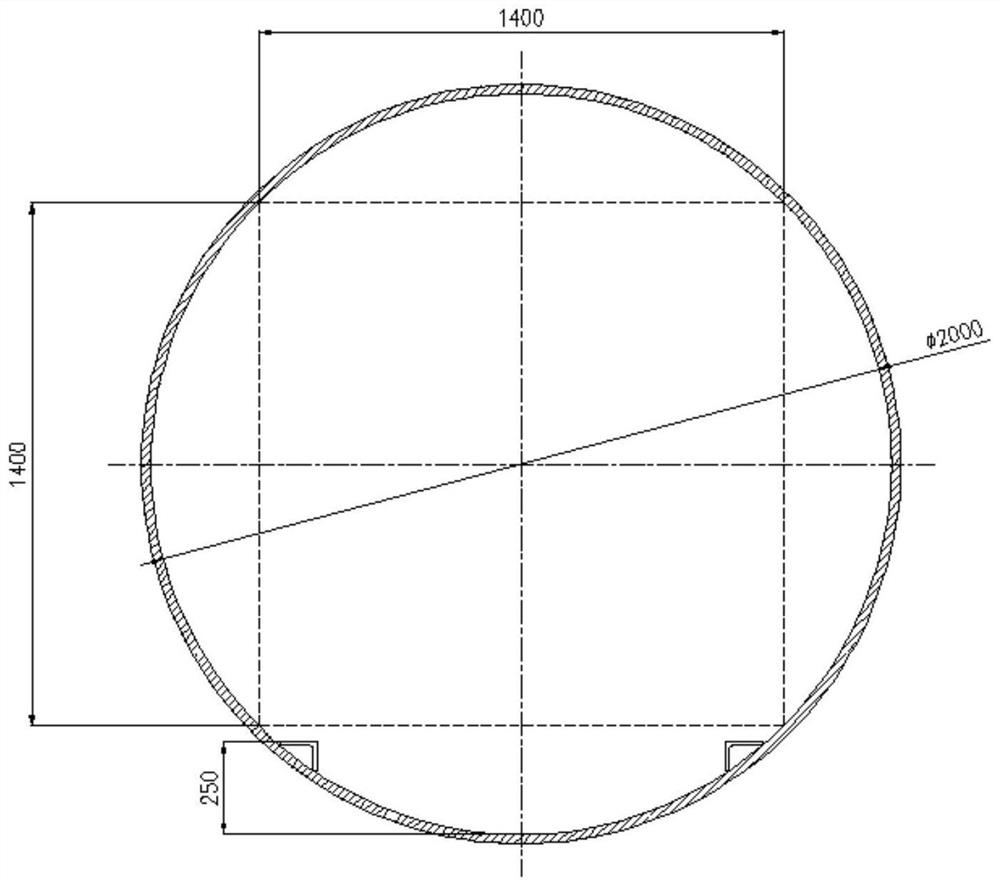

[0037] like figure 2 As shown, the solid rocket motor insulation layer vacuum patch automatic control system includes a large-scale temperature-controlled tank compartment. In the above large-sized temperature-controlled tank compartment, the effective working chamber size diameter mm × length 6000mm, the effective space in the tank is not less than 1400mm (length) × 1400mm (height) × 6000mm (depth), using unequal corners 100 × 80 × 10mm to weld inside the tank, as a trolley track base, length 6m .

[0038] Further, in the above-mentioned large-sized temperature-controlled tank cabin, the tank body is made of carbon steel, and the load weight of the tank body and rail: 2000kg; a spiral heat-conducting oil tank with a width o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com