Processing method of diffusion plate

A processing method and technology of diffuser plates, which are applied in applications, household appliances, flat products, etc., can solve problems such as inability to adapt to high-temperature environments, and achieve the effect of good impact resistance and not easy aging and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

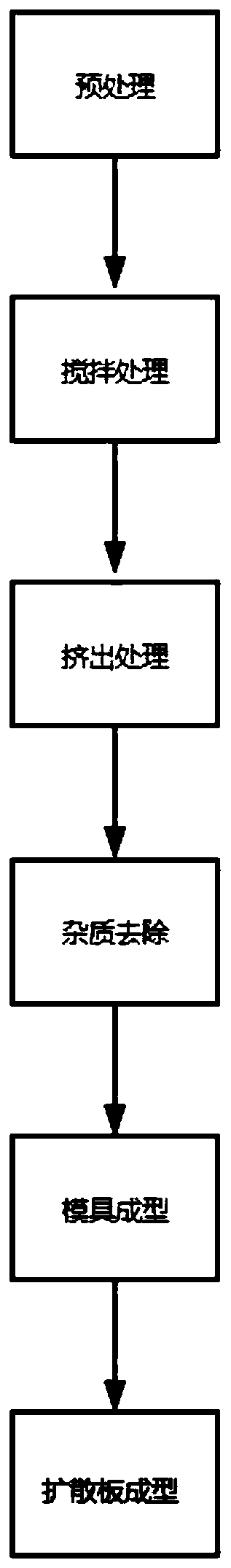

[0025] refer to figure 1 , a method for processing a diffusion plate in a preferred embodiment of the present invention, comprising the following steps,

[0026] Pretreatment: Dry polymethyl methacrylate and diffusing powder separately at 80°C;

[0027] Stirring treatment: Take 100KG of pretreated polymethyl methacrylate and 1.8KG of diffusion powder, and carry out mixing and stirring treatment at a stirring speed of 800r / min;

[0028] Extrusion treatment: When the temperature rises to 200°C-250°C, add the raw materials that have been uniformly stirred in the stirring treatment step into the extruder, and then melt the raw materials into a colloidal substance through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com