Continuous production system and method for producing low-water-content calcium sulfate from waste sulfuric acid

A production system and production method technology, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problem of high energy consumption and achieve the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

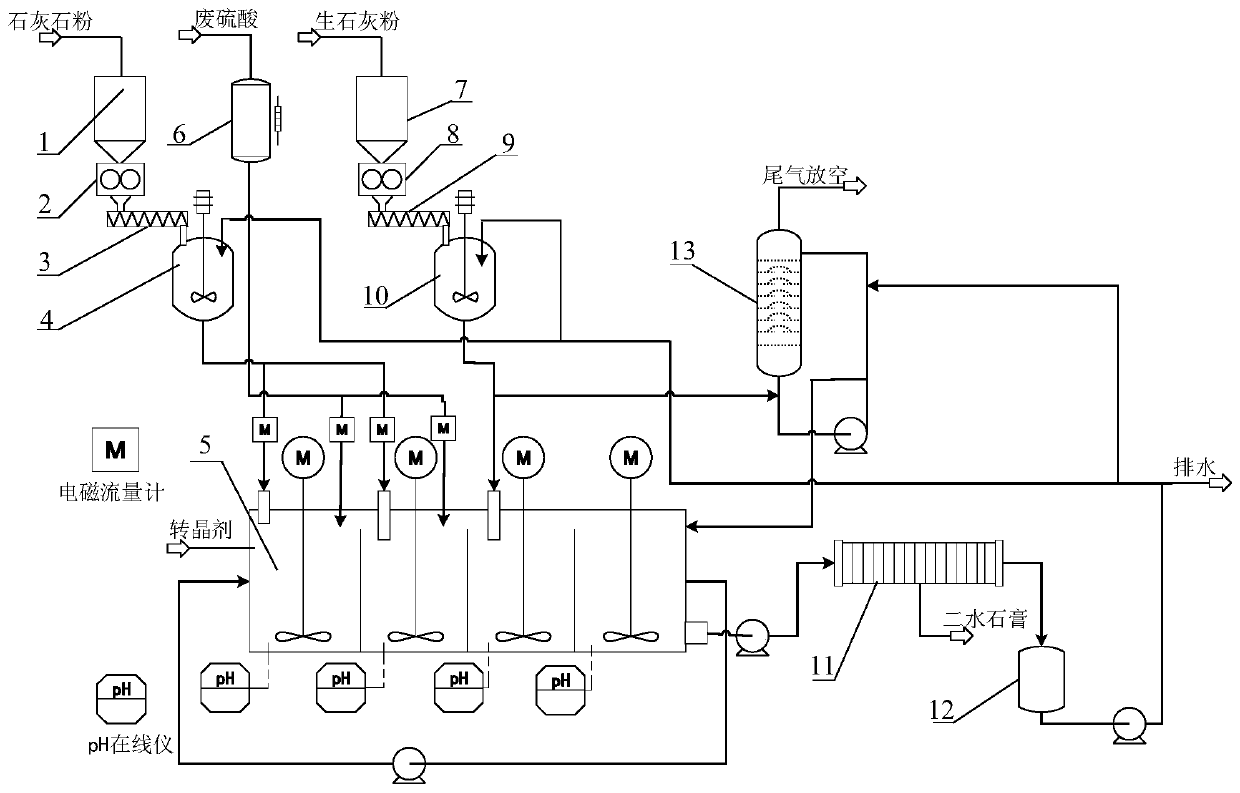

[0086] This embodiment provides a continuous production system for the production of low-water calcium sulfate from waste sulfuric acid. The structural schematic diagram of the continuous production system for the production of low-water calcium sulfate from waste sulfuric acid is figure 1 As shown, it includes a limestone slurry supply unit, a waste sulfuric acid supply unit, a quicklime slurry supply unit, a four-stage continuous reactor, a crystal modifier supply unit, a solid-liquid separation unit, and a tail gas absorption tower 13 .

[0087] The four-stage continuous reactor includes a first-stage reaction chamber, a second-stage reaction chamber, a third-stage reaction chamber and a fourth-stage reaction chamber arranged in sequence; the reactant in the first-stage reaction chamber flows to the second-stage reaction chamber , the reactant material in the second-stage reaction chamber flows to the third-stage reaction chamber, the reactant material in the third-stage rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com