A kind of preparation method of high-efficiency and environment-friendly dual-monomer solid-phase grafted PP

A solid-phase grafting and environment-friendly technology is applied in the field of preparation of dual-monomer solid-phase grafted PP, which can solve the problems of many side reactants, long time, cumbersome preparation method of solid-phase grafted PP, etc., and achieves good appearance, Avoid black spots and yellow grains, the effect of low reaction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

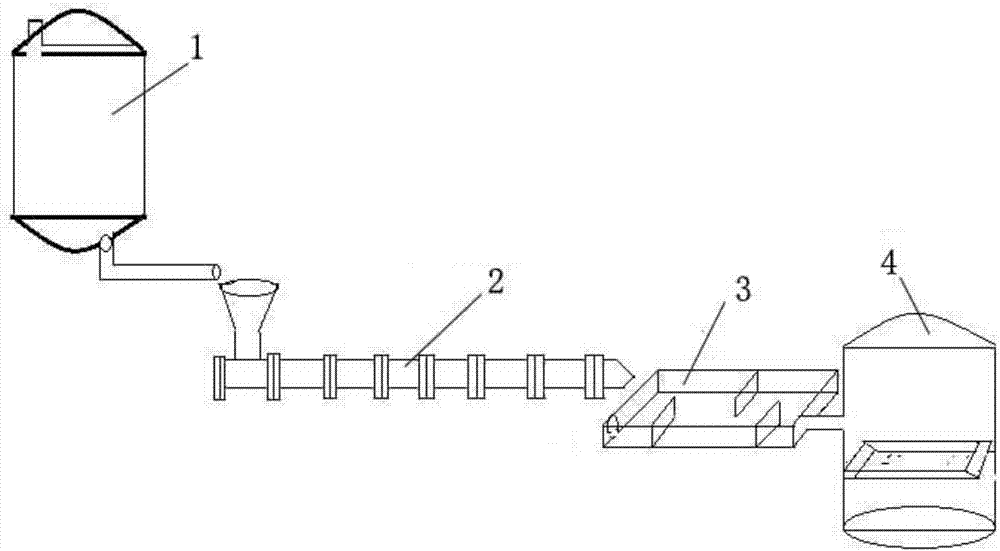

[0019] The invention provides a kind of high-efficiency and environment-friendly preparation method of dual-monomer solid-phase grafted PP comprising the following steps, combining figure 1 Shown:

[0020] Reaction mixture: prepare raw materials with the following proportions by weight: 100 parts of polypropylene powder, 1.0 to 2.0 parts of glycidyl methacrylate, 0.8 to 1.5 parts of maleic anhydride, 1.0 to 1.5 parts of benzoyl peroxide, and The above raw materials are introduced into the mixing tank 1 to obtain a uniformly mixed reaction mixture, wherein the mixing power and time can be manually set according to the actual situation;

[0021] Pre-grafting: Set the temperature in the mixing tank 1 to 50°C to 60°C, and heat for 0.5h to 1.0h; the monomer can be turned into a molten state, which can not only be coated on the outer surface of PP powder, but also act To infiltrate and swell PP, increase the reaction interface, and with the extension of swelling time, the monomer p...

Embodiment 1

[0025] Prepare the raw materials that parts by weight are the following ratios: the parts by weight of glycidyl methacrylate, maleic anhydride, and benzoyl peroxide are respectively 1.6 parts, 1.2 parts, and 1.2 parts, and the above-mentioned raw materials are imported in the mixing tank 1 Low mixing to obtain a uniformly mixed reaction mixture;

[0026] Pre-grafting: Set the temperature in the mixing tank 1 to 50°C and heat for 1.0h; the monomer can be turned into a molten state, which helps to increase the grafting rate;

[0027] Preparation of solid-phase grafted PP: import the pre-grafted reaction material into the screw extruder 2, remove the initial reaction product at the discharge port, and start grafting after 5 minutes when the appearance is stable; the temperature in the reaction zone is 130°C, and the temperature in the discharge zone 0°C, adjust the process parameters to 50r / min after starting up, and adjust the feeding according to the current;

[0028] Post-tre...

Embodiment 2

[0030] The difference with embodiment 1 is:

[0031] Prepare raw materials with the following ratios in parts by weight: the parts by weight of glycidyl methacrylate, maleic anhydride, and benzoyl peroxide are respectively 1.42 parts, 1.16 parts, and 1.42 parts;

[0032] Pre-grafting: set the temperature in mixing tank 1 to 55°C and heat for 0.8h;

[0033] Post-treatment of grafted products: wash the reaction product with water at 20° C. for 10 minutes in the serpentine water tank 3 .

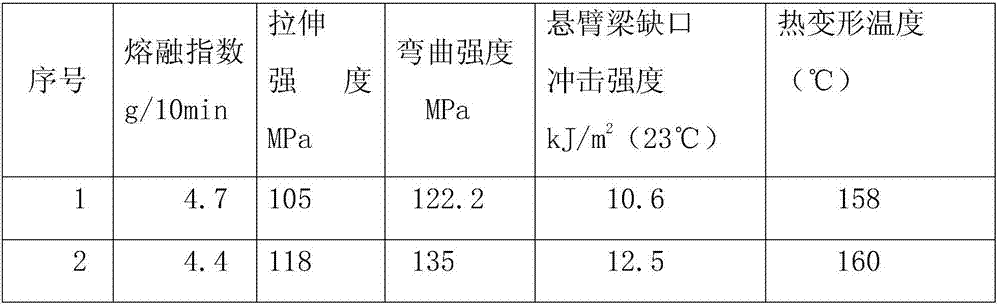

[0034] Embodiment 1 and Embodiment 2 are preferred embodiments of the present invention. The grafted PP obtained in the above two embodiments is mixed evenly with PPT30S and glass fiber 635B respectively, and the ratio is 1:13:6, which is reinforced by 1#35 The twin-screw extruder was extruded and granulated when the process parameters were 240°C / 400rpm / 7Hz, and then injected into the national standard B1-type spline through a 68 injection molding machine. After standing at 25°C for 48 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com