MVR multi-effect evaporation condensate recycling system

A technology of multi-effect evaporation and condensing water, applied in multi-effect evaporation, heating water/sewage treatment, etc., can solve the problem of ineffective use of energy, save energy and water resources, improve energy utilization, and avoid energy loss wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

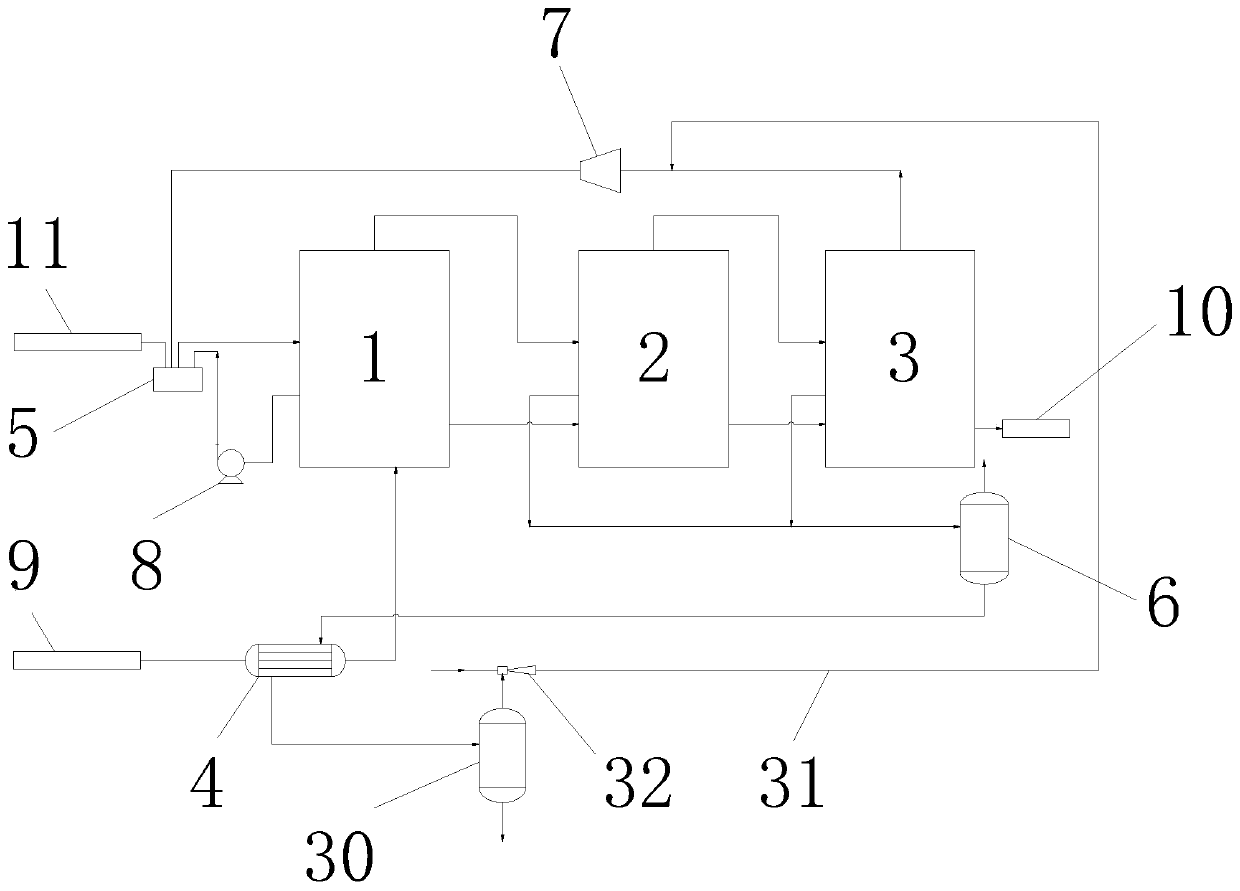

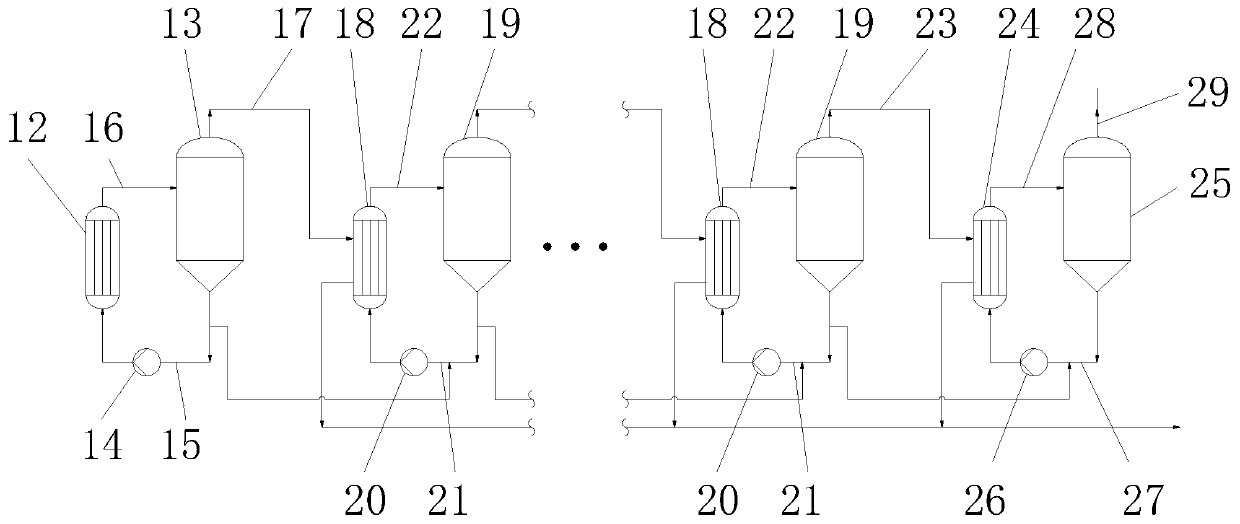

[0020] Embodiment 1 of the present invention: as figure 1 As shown, a condensed water recycling system of MVR multi-effect evaporation includes a first-effect evaporation group 1, a group of intermediate evaporation groups 2, a tail-effect evaporation group 3, a preheater 4, a steam saturator 5, a condensed water tank 6, Compressor 7, condensate pump 8, raw material liquid pipeline 9, concentrated liquid pipeline 10 and raw steam pipeline 11, the first effect evaporation group 1, the middle effect evaporation group 2 and the tail effect evaporation group 3 are connected in series in sequence, and the raw steam pipeline 11 is connected to the steam saturator 5, and the steam saturator 5 is also connected to the first-effect evaporation group 1 through pipelines. The condensed water produced by the first-effect evaporation group 1 enters the steam saturator 5 through the pipeline and the condensate pump 8, and the middle evaporation group 2 and the tail The condensed water produ...

Embodiment 2

[0024] Embodiment 2 of the present invention: as figure 1 As shown, a condensed water recycling system of MVR multi-effect evaporation includes a first-effect evaporation group 1, a group of intermediate evaporation groups 2, a tail-effect evaporation group 3, a preheater 4, a steam saturator 5, a condensed water tank 6, Compressor 7, condensate pump 8, raw material liquid pipeline 9, concentrated liquid pipeline 10 and raw steam pipeline 11, the first effect evaporation group 1, the middle effect evaporation group 2 and the tail effect evaporation group 3 are connected in series in sequence, and the raw steam pipeline 11 is connected to the steam saturator 5, and the steam saturator 5 is also connected to the first-effect evaporation group 1 through pipelines. The condensed water produced by the first-effect evaporation group 1 enters the steam saturator 5 through the pipeline and the condensate pump 8, and the middle evaporation group 2 and the tail The condensed water produ...

Embodiment 3

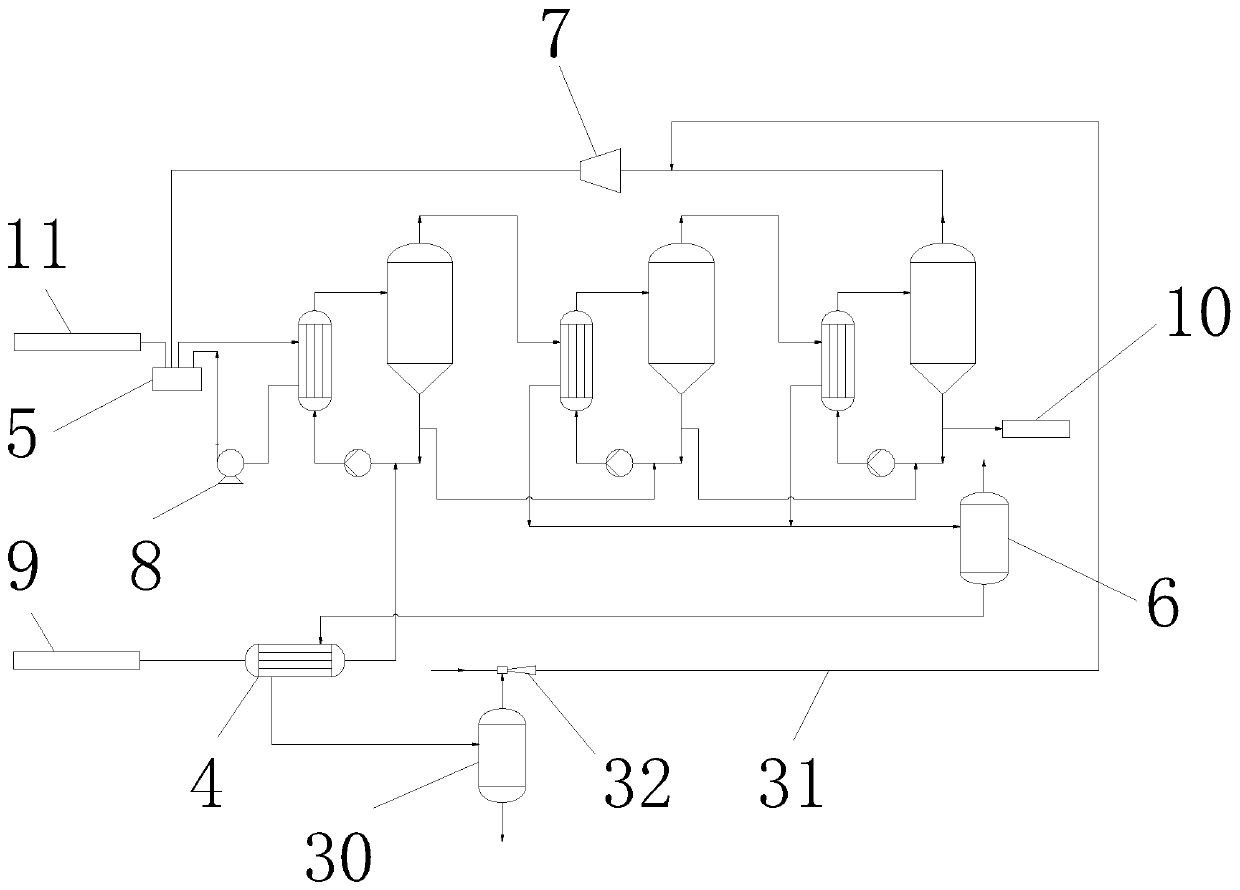

[0029] Embodiment 3 of the present invention: as figure 1 As shown, a condensed water recycling system for MVR multi-effect evaporation includes a first-effect evaporation group 1, two intermediate evaporation groups 2, a tail-effect evaporation group 3, a preheater 4, a steam saturator 5, a condensed water tank 6, Compressor 7, condensate pump 8, raw material liquid pipeline 9, concentrated liquid pipeline 10 and raw steam pipeline 11, the first effect evaporation group 1, the two intermediate evaporation groups 2 and the tail effect evaporation group 3 are connected in series in sequence, close to the first effect The middle evaporation group 2 of the evaporation group 1 is the second evaporation group, and the middle evaporation group 2 close to the tail effect evaporation group 3 is the third evaporation group. The raw steam pipeline 11 is connected with the steam saturator 5, and the steam saturator 5 is also passed through The pipeline is connected to the first effect ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com