Reflective grating gradient color explosion-proof membrane and preparation method thereof

An explosion-proof film, gradient color technology, applied in diffraction grating, optics, optical components, etc., can solve the problem of difficult product appearance uniformity, and achieve the effect of being conducive to industrialized mass production, good consistency, and reducing production scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

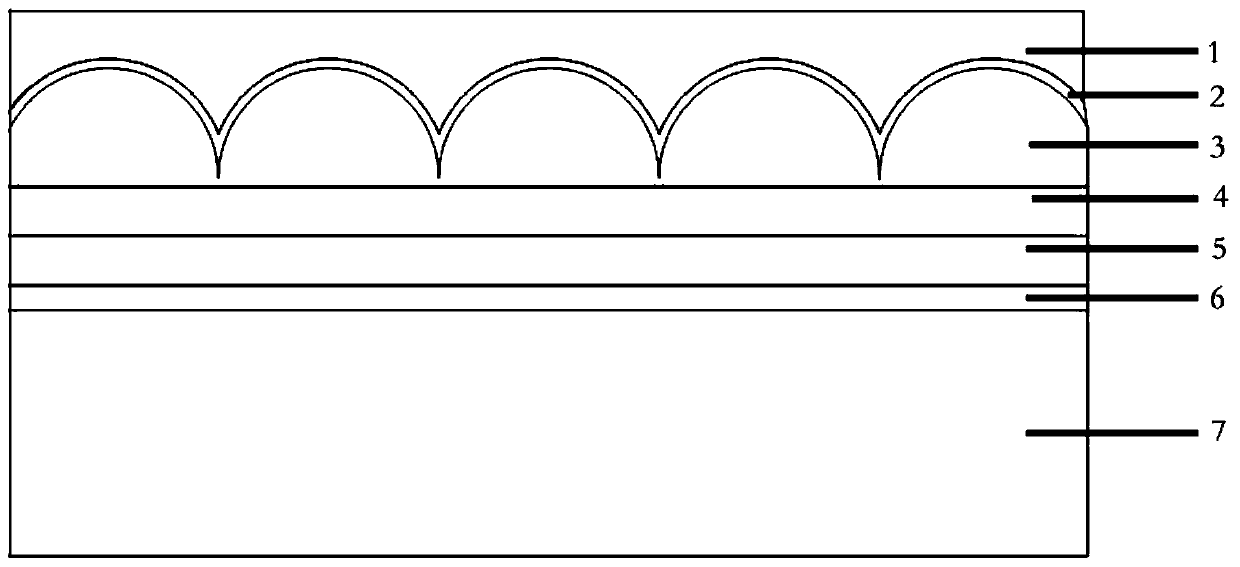

[0031] refer to Figure 1-2 , a reflective grating gradient color explosion-proof film in this embodiment, including an ink layer 1, a reflective layer 2, a UV structure layer 3, a PET explosion-proof film layer 4 and a multi-color printing layer 5 arranged sequentially from top to bottom, the ink Layer 1 is formed by printing with silk screen printing equipment, the reflective layer 2 is formed by coating with a coating machine, the UV structure layer 3 is formed by curing UV glue, the UV structure layer 3 is a lenticular structure, and the multi-color printing layer 5 is formed by printing with a high-precision printing machine.

[0032] The ink layer 1 is used to protect the reflective layer 2 and further prevent light leakage; the reflective layer 2 is used to reflect light; the UV structural layer 3 is used to reflect the color of the printing layer through the lenticular grating of the UV structural layer 3; the PET explosion-proof film layer 4 is used as the carrier of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com