Fully-prefabricated hybrid bearing house and construction method

A load-bearing and housing technology, applied in building components, walls, buildings, etc., to achieve the effects of reasonable stress, short construction period and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

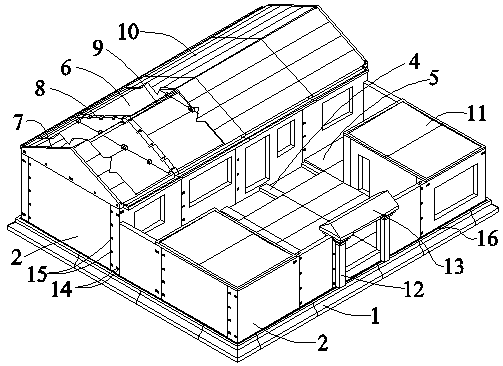

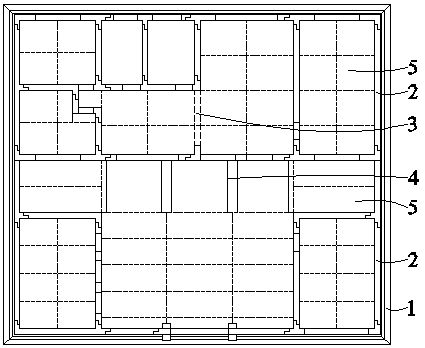

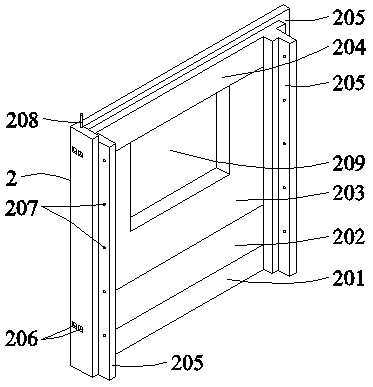

[0030] Such as Figure 1-Figure 2As shown, a fully prefabricated mixed load-bearing house consists of a strip foundation (1), mixed wall panels (2), beams (3), ground beams (4), floor panels (5), ceiling panels (6), Gable board (7), mid-wall board (8), steel support (9), roof board (10), platform board (11), door stack (12), gate tower (13), finish-rolled rebar (14), Composed of bolts (15) and fine stone concrete (16); the strip foundation is prefabricated in sections (1), with a long groove in the middle; the mixed wall panel (2) is inserted in the groove of the strip foundation (1), and the mixed wall The gap between the slab (2) and the strip foundation (1) is filled with fine stone concrete (16), the two mixed wall panels (2) are connected by bolts (15), and multiple mixed wall panels (2) form The full-length wall is compacted by applying pre-compression stress through the finished rolled rebar (14), and the nuts are tightened to connect it as a whole; the beam (3) is pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com