Drying device for air pipeline of paving material combustion test device

An air pipeline and combustion test technology, which is applied in the direction of chemical analysis, material analysis, and measuring devices by means of combustion, can solve the problems of long air compressor pipelines, air detection, and large gas consumption, so as to increase the flow distance and save energy. space, effect of increased contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

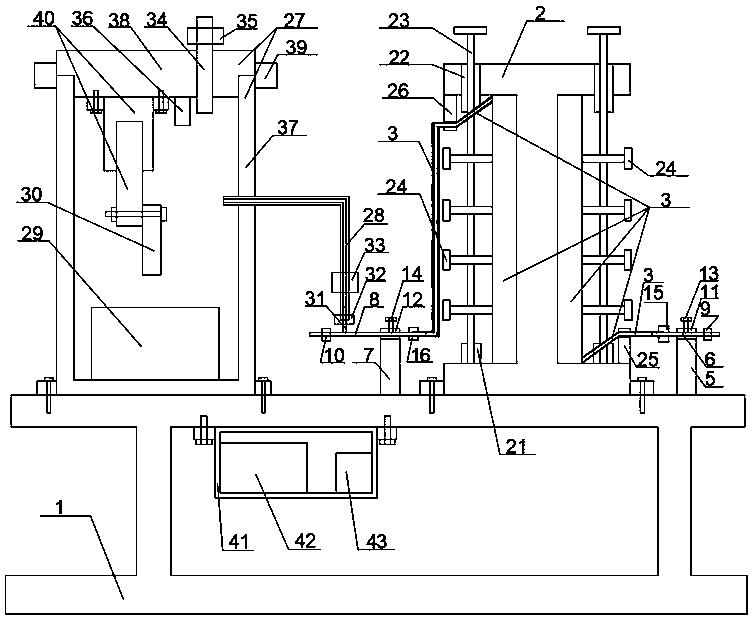

[0037] like Figure 1-7 As shown, a drying device for the air pipeline of the flooring material combustion test device, including a fixed frame 1, a drying module arranged at the right end of the fixed frame 1, and a detection module arranged at the left end of the fixed frame 1 and connected to the drying module ;

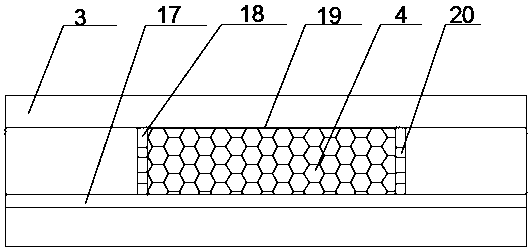

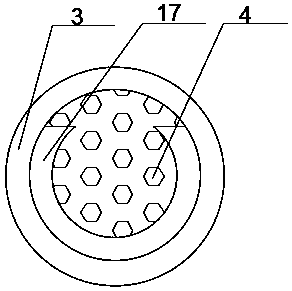

[0038] The drying module includes a wheel 2 arranged at the top right end of the fixed frame 1, an air duct 3 wound on the wheel 2, a desiccant 4 arranged in the air duct 3, and a top right end arranged at the top of the fixed frame 1 and located at The first mounting frame 5 on the right side of the wheel disc 2, the air intake pipe 6 arranged in the first mounting frame 5, the second mounting frame 7 arranged at the top right end of the fixed frame 1 and positioned at the left side of the wheel disc 2, and the second mounting frame 7 arranged on the left side of the wheel disc 2. The air outlet pipe 8 in the second installation frame 7;

[0039]One end of the ...

Embodiment 2

[0074] The difference between this embodiment and Embodiment 1 is that: the first valve switch 9 , the second valve switch 10 , the third valve switch 33 , and the fourth valve switch 35 are all one-way valve switches.

[0075] Through the first valve switch 9, the air can only flow from the air intake pipe 6 to the air guide pipe 3, but cannot flow from the air guide pipe 3 to the air intake pipe 6, thereby preventing the dried air from being re-humidified;

[0076] Through the second valve switch 10, the air produced by the air compressor can only flow from the air outlet pipe 8 to the flooring material combustion experimental device, and cannot flow in the opposite direction, thereby avoiding the dried air from being re-wetted or polluted;

[0077] Through the third valve switch 33, the dried air can only flow from the air outlet pipe 8 to the exhaust branch pipe 31 and then to the extension pipe 28, and cannot flow in the opposite direction, thereby preventing the dried air f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com