Novel optical mask plate with different light transmission properties

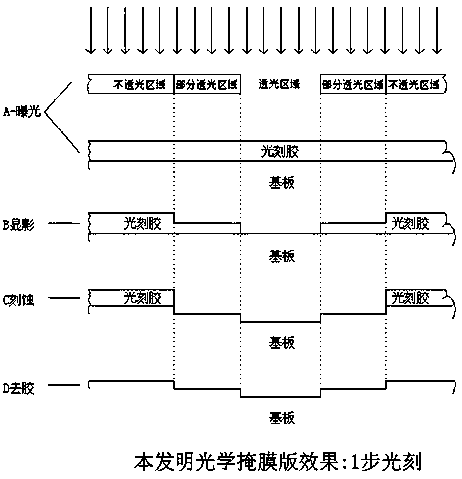

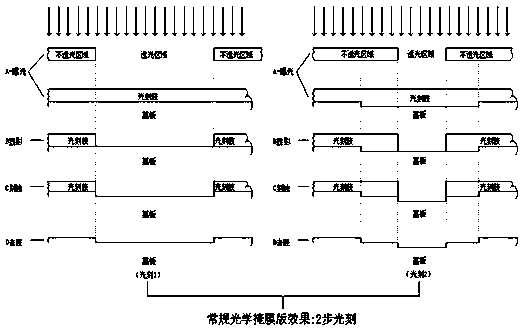

An optical mask and light transmittance technology, applied in the field of lithography, can solve the problems of cumbersome preparation process, reduce lithography steps, achieve the effect of size and height, and meet the requirements of lithography masks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

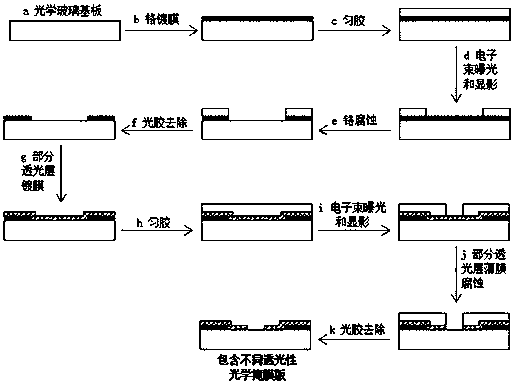

[0036] A novel optical mask comprising different light transmittances, the preparation method of which comprises the following steps:

[0037] a. Select optical glass with high transmittance in the ultraviolet band as the substrate of the optical mask;

[0038] b. Coating a layer of chromium metal film on the surface of the glass substrate;

[0039] c. Uniformly coat a layer of photoresist on the glass substrate coated with chrome film;

[0040] d. Set the photoresist in the pattern area by electron beam exposure to make it react, and then develop it with a developer to finally form a glass substrate with a photoresist pattern;

[0041] e. Soak the etching solution to remove the chromium film in the area not covered by the photoresist, and keep the rest;

[0042] f. Remove the remaining photoresist to form a glass substrate with fully transparent and fully blocked light design graphics;

[0043] g. Continue to coat a layer of partially light-transmitting film on the glass s...

Embodiment 2

[0061] A novel optical mask comprising different light transmittances, the preparation method of which comprises the following steps:

[0062] a. Select optical glass with high transmittance in the ultraviolet band as the substrate of the optical mask;

[0063] b. Coating a layer of chromium metal film on the surface of the glass substrate;

[0064] c. Uniformly coat a layer of photoresist on the glass substrate coated with chrome film;

[0065] d. Set the photoresist in the pattern area by electron beam exposure to make it react, and then develop it with a developer to finally form a glass substrate with a photoresist pattern;

[0066] e. Soak the etching solution to remove the chromium film in the area not covered by the photoresist, and keep the rest;

[0067] f. Remove the remaining photoresist to form a glass substrate with fully transparent and fully blocked light design graphics;

[0068] g. Continue to coat a layer of partially light-transmitting film on the glass s...

Embodiment 3

[0082] A novel optical mask comprising different light transmittances, the preparation method of which comprises the following steps:

[0083] a. Select optical glass with high transmittance in the ultraviolet band as the substrate of the optical mask;

[0084] b. Coating a layer of chromium metal film on the surface of the glass substrate;

[0085] c. Uniformly coat a layer of photoresist on the glass substrate coated with chrome film;

[0086] d. Set the photoresist in the pattern area by electron beam exposure to make it react, and then develop it with a developer to finally form a glass substrate with a photoresist pattern;

[0087] e. Soak the etching solution to remove the chromium film in the area not covered by the photoresist, and keep the rest;

[0088] f. Remove the remaining photoresist to form a glass substrate with fully transparent and fully blocked light design graphics;

[0089] g. Continue to coat a layer of partially light-transmitting film on the glass s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com