Printing ink traceability production process method based on block chain

A technology of printing ink and production process, which is applied in the field of traceable production process of printing ink based on blockchain, can solve the problems of ink falling off, not reaching, filling and packaging damage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

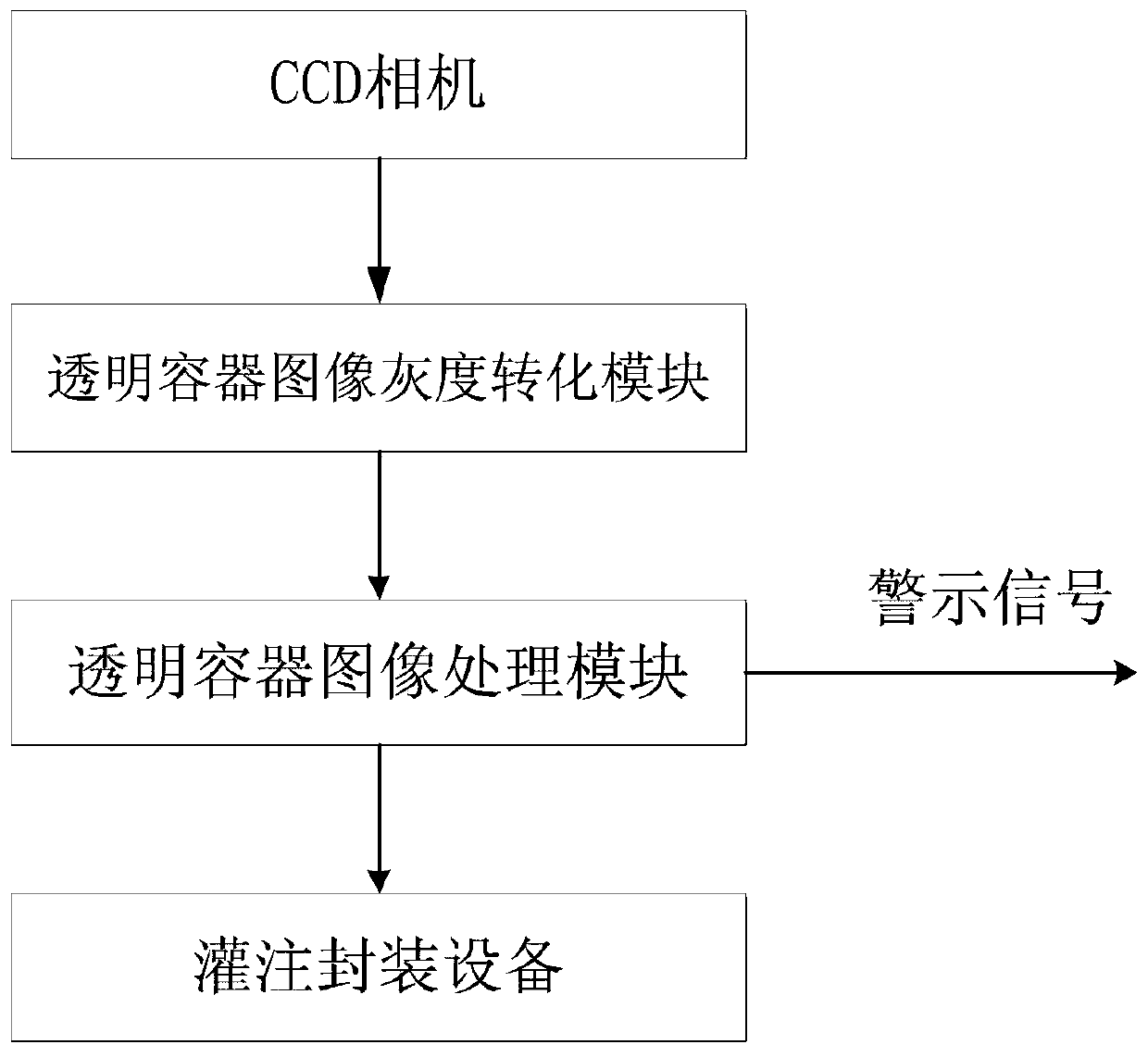

[0046] refer to figure 1 , the present embodiment provides a blockchain-based printing ink traceability production process method, comprising the following steps:

[0047] S1: uniformly mix 1-2 parts of acetic acid and 28-33 parts of water-based saturated polyester resin solution by weight to obtain a first mixed solution, and make the pH of the first mixed solution between 7.6-8.3;

[0048] S2: Mix 0.2-0.4 parts of beeswax, 6-9 parts of low-odor slow-drying emulsion and 0.6-1.4 parts of antifoaming agent in parts by weight to obtain a second mixed solution, and then add the second mixed solution to the first Mix evenly in the mixed solution and perform emulsification treatment to obtain an emulsion;

[0049] S3: Mix 25-29 parts of low-odor quick-drying emulsion, 31-35 parts of color paste and 4-6 parts of varnish in parts by weight to obtain a third mixed liquid, and then add the third mixed liquid to the Mix evenly in the emulsion, and make the pH between 7.2 and 7.9 to ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com