Integrated machine for reducing barrel plate of packaging barrel

A technology of packaging barrels and an all-in-one machine, which is applied to shearing devices, accessories of shearing machines, metal processing machinery parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

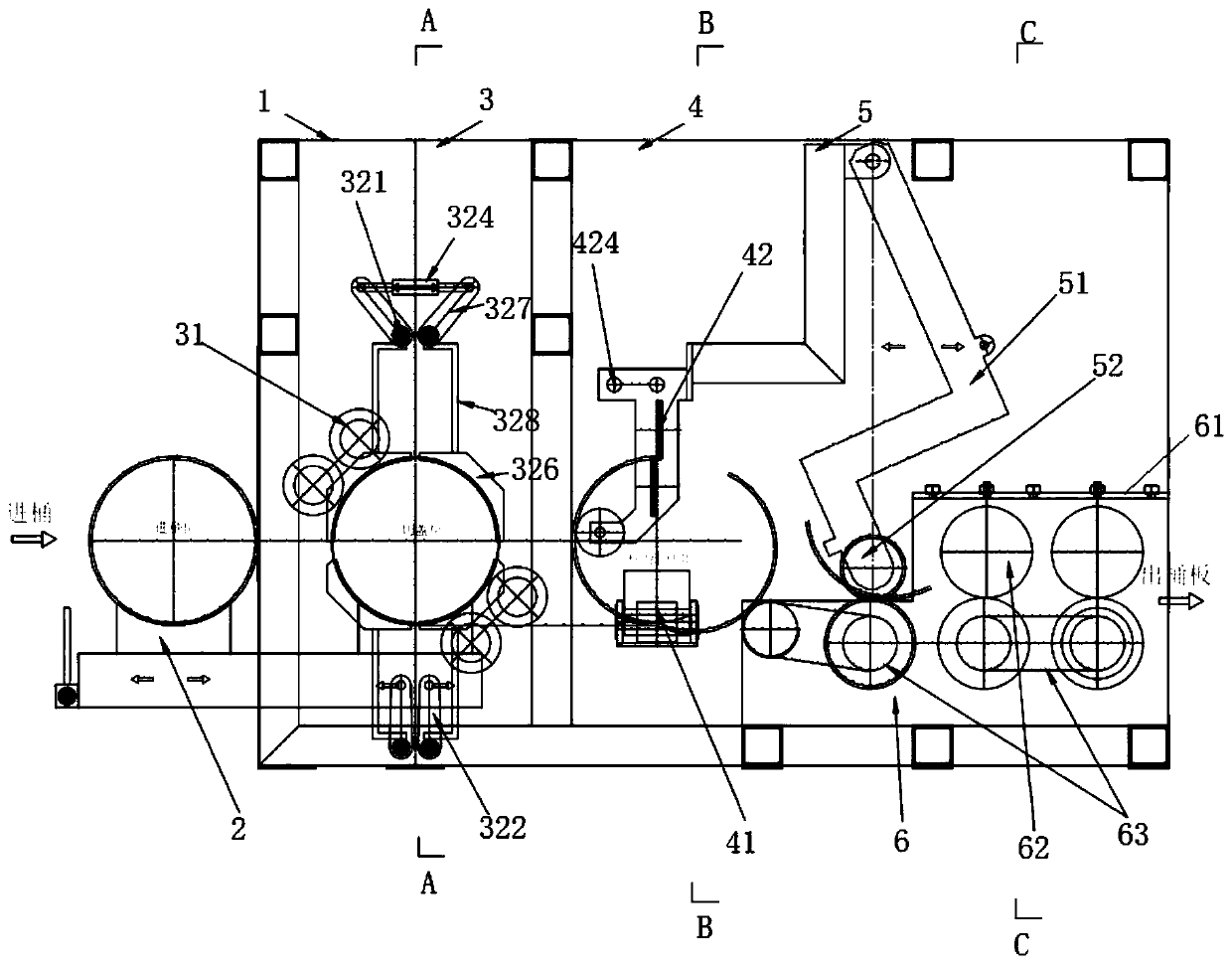

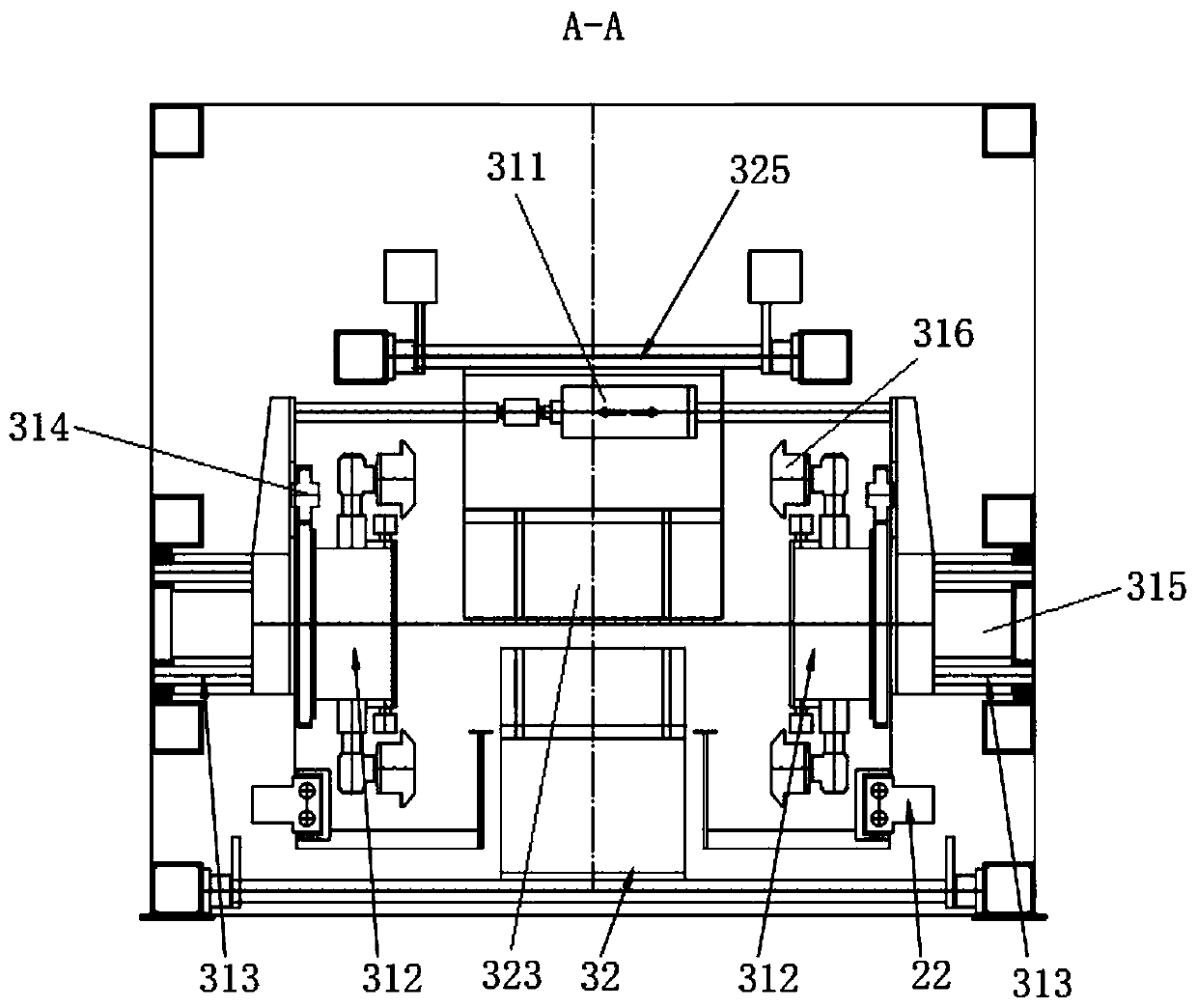

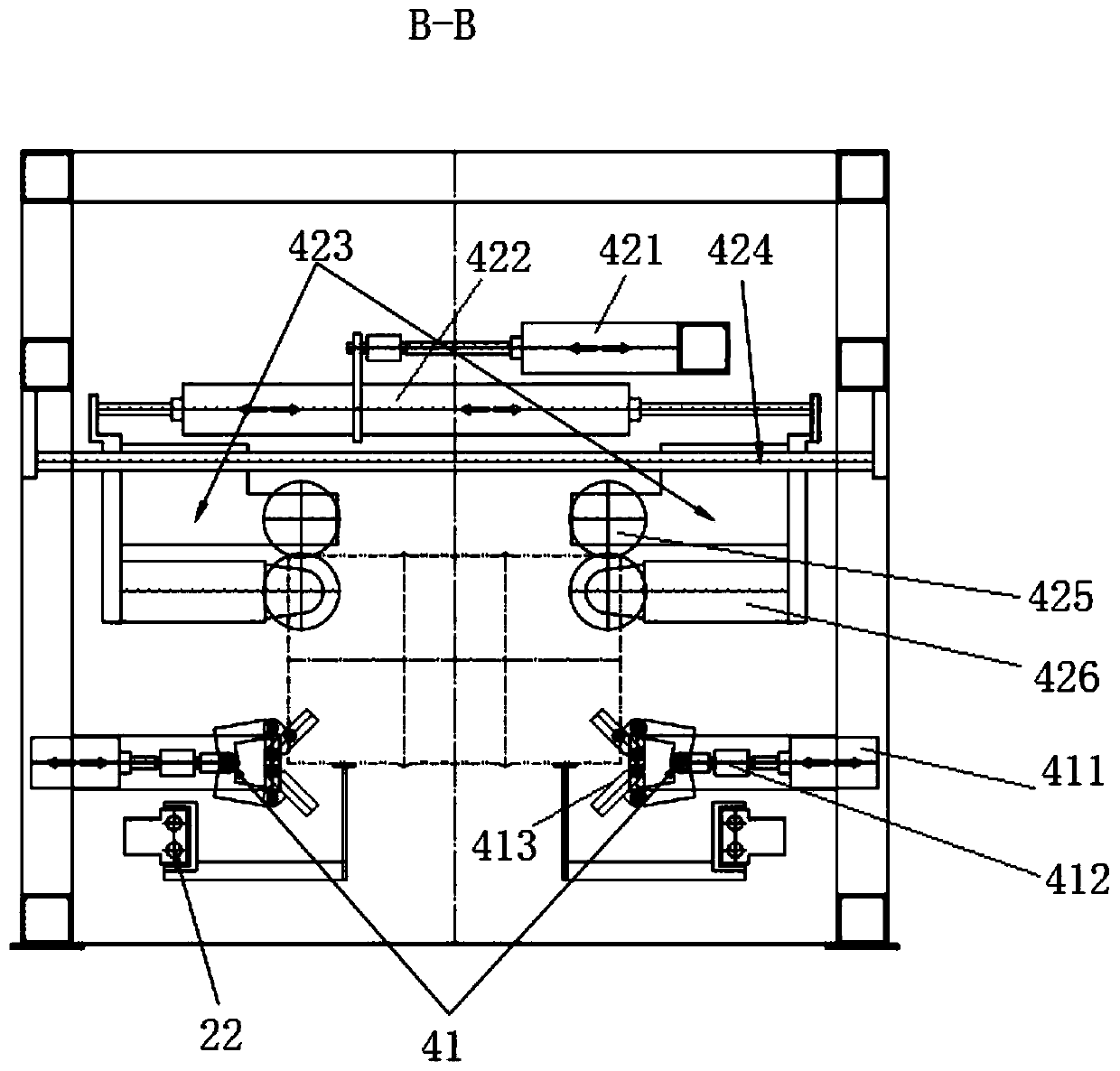

[0040] Such as Figure 1-6 As shown, this embodiment provides an integrated machine for reducing barrels and staves of packaging barrels, including a closed overall frame 1, a barrel feeding mechanism 2 integrated on the overall frame 1, a lid cutting mechanism 3, and a longitudinal cutting mechanism for barrels. Mechanism 4, iron sheet unfolds feeding mechanism 5 and iron sheet unfolds plate mechanism 6. in:

[0041] Such as figure 1 , 5, 6, the bucket feeding mechanism 2 is arranged at the bottom of one side of the overall frame 1, and two arc-shaped bucket positions are arranged side by side on the station plate 23, namely the first bucket position 24 and the second bucket position 25 In most cases, the first barrel position 24 is positioned as the barrel-in position, and the second barrel position 25 is the cover-cutting position, which overlaps with the cover-cutting mechanism 3 .

[0042] In this embodiment, the vertical displacement transmission device 21 only moves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com