Anti-skid, oil-stain-resistant and high-temperature-resistant double-pneumatic gripper device

A gripper device and high-temperature-resistant technology, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of separation of cold and hot ends without grippers, no protection, gripper corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

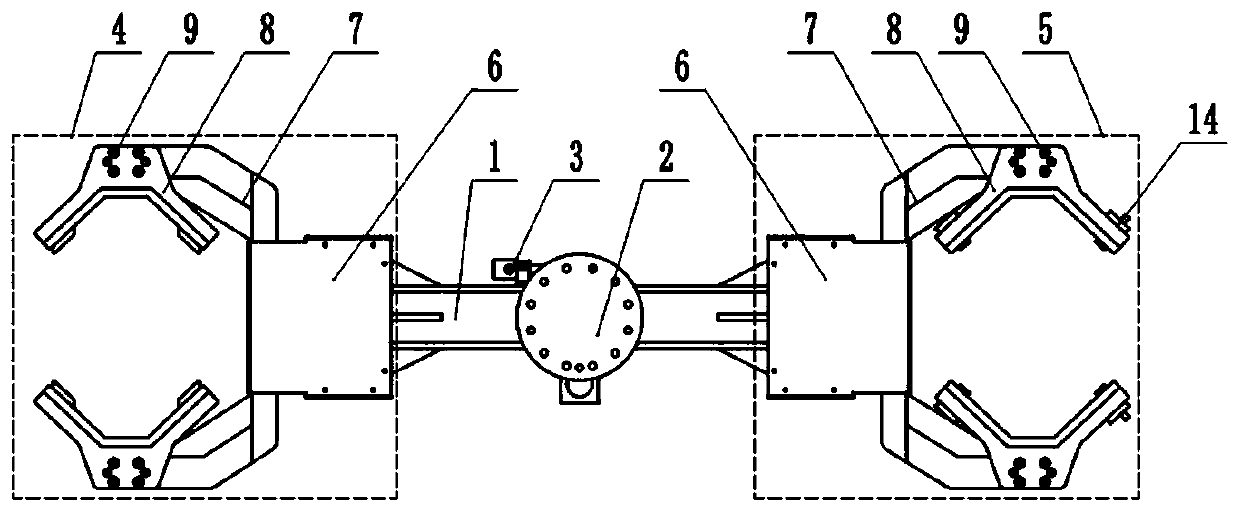

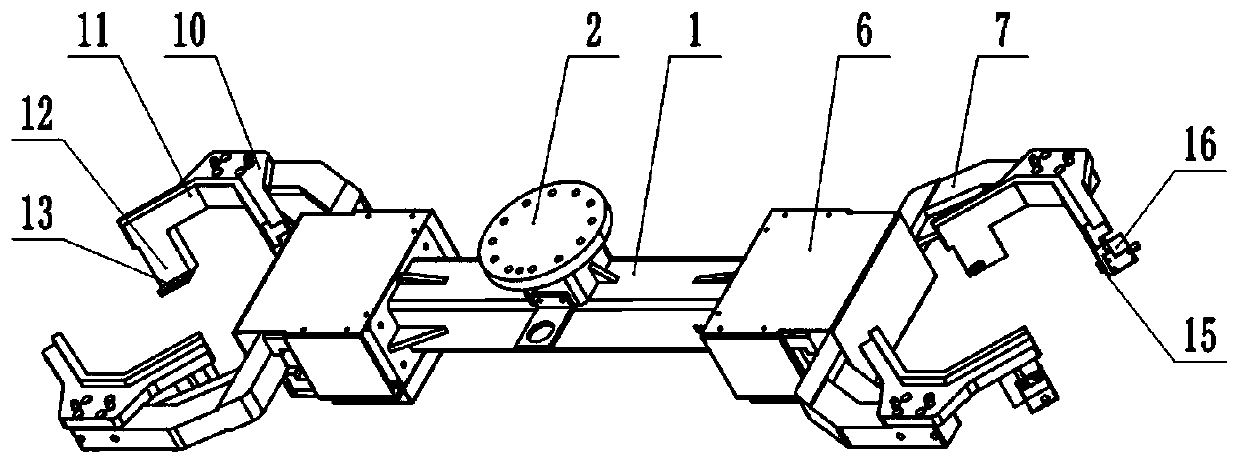

[0025] Basic as attached figure 1 , attached figure 2 Shown: a non-slip, anti-oil and high-temperature-resistant double pneumatic gripper device, including a beam 1, a pipeline connection seat 2, a cooling gun 3, and a hot end gripper 4 and a cold end gripper 5 fixed at both ends of the crossbeam 1, The pipeline connection seat 2 is fixed on the middle part of the beam 1.

[0026] Both the hot end gripper 4 and the cold end gripper 5 include a cylinder, two gripper connecting blocks 7 and two V-shaped fingers 8, the V-shaped fingers 8 are made of high temperature resistant stainless steel, and the gripper connecting blocks 7 are made of Made of aviation aluminum alloy material. The cylinder is fixed on the crossbeam 1, and the cylinder protective cover 6 is arranged outside the cylinder, and the two gripper connection blocks 7 are fixedly connected with the output end of the cylinder, and the two gripper connection blocks 7 are arranged symmetrically; the two V-shaped finge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com