An industrial wastewater treatment device

A technology for treatment device and industrial wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problem of inability to put chemicals in proportion and improve filtration efficiency. , the effect of reducing the time interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

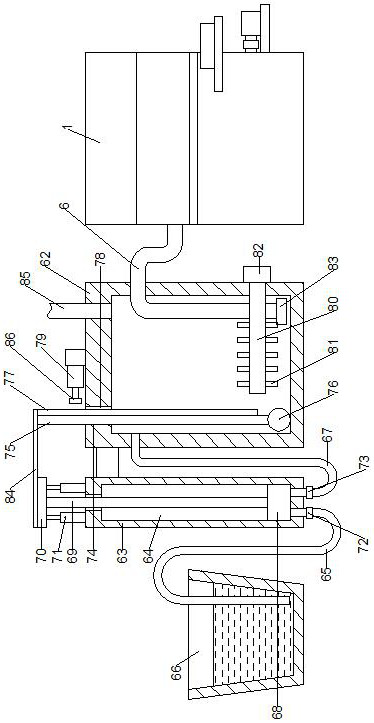

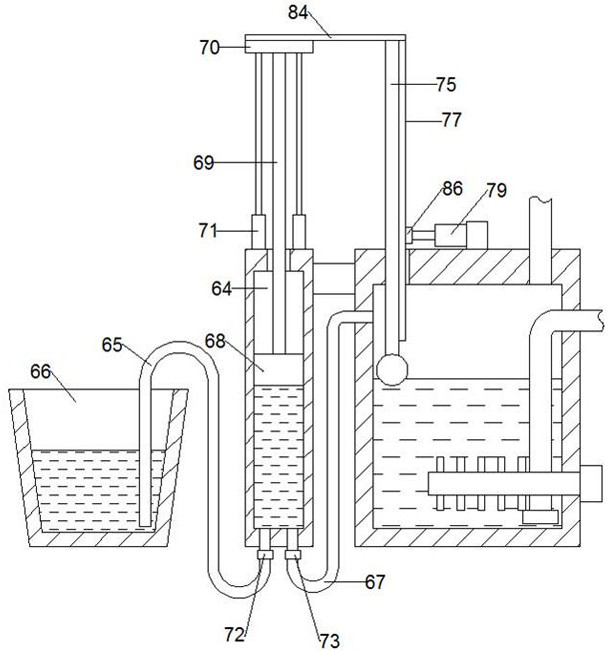

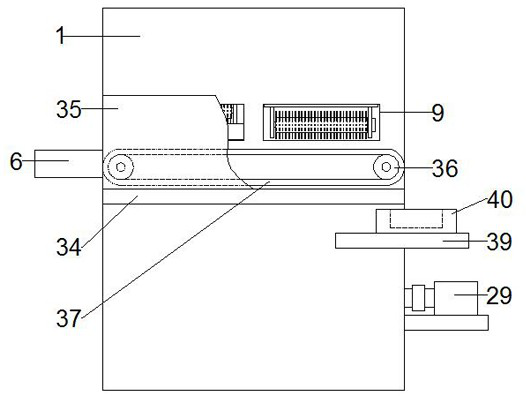

[0028] Such as Figure 1 to Figure 7 As shown, an industrial wastewater treatment device includes a first box body 62, the first box body 62 is provided with a sewage inlet pipe 85 and a sewage discharge pipe 6, and the first box body 62 is provided with a dosing mechanism, so A stirring mechanism is also provided in the first casing 62, and the sewage pipe 6 is connected with a secondary treatment mechanism; the dosing mechanism includes a side dosing box 63 fixedly installed on the first casing 62, so that The dosing box 63 is provided with a dosing chamber 64 extending vertically, the bottom of the dosing chamber 64 is connected with a medicine supply barrel 66 through a first flexible pipe 65, and the bottom of the dosing chamber 64 is also passed through a second hose. The hose 67 is connected with the first box body 62; a piston 68 is movable up and down in the dosing chamber 64, and a vertically extending piston rod 69 is fixedly mounted on the piston 68, and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com