Calcium vanadate slurry filtering system and method for realizing filtration by using same

A calcium vanadate and slurry technology, applied in the field of vanadium chemical industry, can solve the problems of high water inclusion in the filter residue, slow down the filtration speed, slow filtration speed, etc., and achieve the effects of controlling the filtration temperature, avoiding waste and fast filtration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This example provides a method for filtering using a calcium vanadate slurry system for filtering.

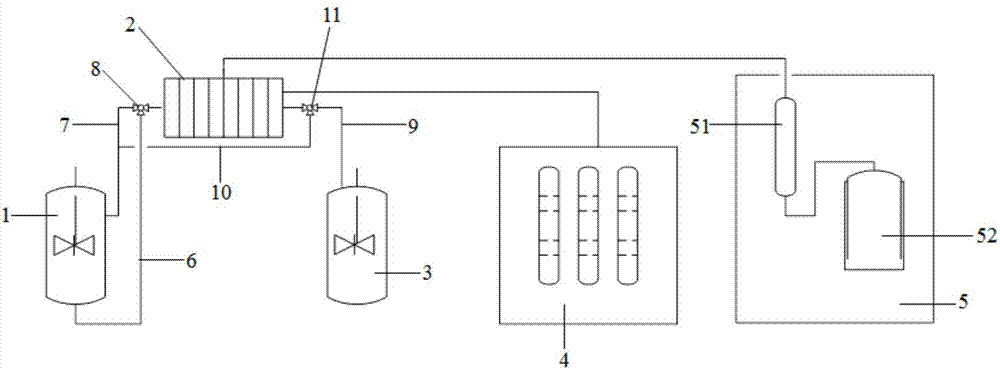

[0062] Among them, the structural schematic diagram of the calcium vanadate slurry system is as follows: figure 1 As shown, it includes a slurry pretreatment device (1), a filter device (2), a storage device (3), a washing device (4) and a backflushing device (5). The slurry pretreatment device is a slurry treatment tank, the filter device is a single disc vacuum filter, the storage device is a filtrate buffer tank, the washing device is a three-stage countercurrent scrubber, and the back blowing device includes a pressure tank (51) and an air storage tank ( 52).

[0063] The discharge port of the slurry pretreatment device (1) is communicated with the feed inlet of the filter device (2) through the first conveying pipeline (6), and the upper part of the slurry pretreatment device (1) is provided with a return port, and the return port is connected to the The first ret...

Embodiment 2

[0070] This example provides a method for filtering using a calcium vanadate slurry system for filtering.

[0071] Wherein, the calcium vanadate slurry filtering system includes a slurry pretreatment device, a filtering device, a storage device, a washing device and a backflushing device. The slurry pretreatment device is a slurry treatment tank, the filter device is a single-disc vacuum filter, the storage device is a filtrate buffer tank, the washing device is a three-stage countercurrent scrubber, and the back blowing device includes a pressure tank and an air storage tank.

[0072] The discharge port of the slurry pretreatment device is connected with the feed port of the filter device through the first conveying pipeline. A delivery pipeline is commonly connected to the feed port of the filter device through the first three-way valve. The discharge port of the filter device is connected with the feed port of the storage device through the second conveying pipe, and a sec...

Embodiment 3

[0079] This example provides a method for filtering using a calcium vanadate slurry system for filtering.

[0080] Wherein, the calcium vanadate slurry filtering system includes a slurry pretreatment device, a filtering device, a storage device, a washing device and a backflushing device. The slurry pretreatment device is a slurry treatment tank, the filter device is a single-disc vacuum filter, the storage device is a filtrate buffer tank, the washing device is a three-stage countercurrent scrubber, and the back blowing device includes a pressure tank and an air storage tank.

[0081]The discharge port of the slurry pretreatment device is connected with the feed port of the filter device through the first conveying pipeline. A delivery pipeline is commonly connected to the feed port of the filter device through the first three-way valve. The discharge port of the filter device is connected with the feed port of the storage device through the second conveying pipe, and a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com