A kind of purposes of pyrogallic acid in silicon dioxide polishing

A technology of pyrogallic acid and silicon dioxide, applied in polishing compositions containing abrasives, etc., can solve the problems of inability to play butterfly defects, increase the production cost of polishing liquid, etc., achieve quality improvement, avoid damage, prolong shelf life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

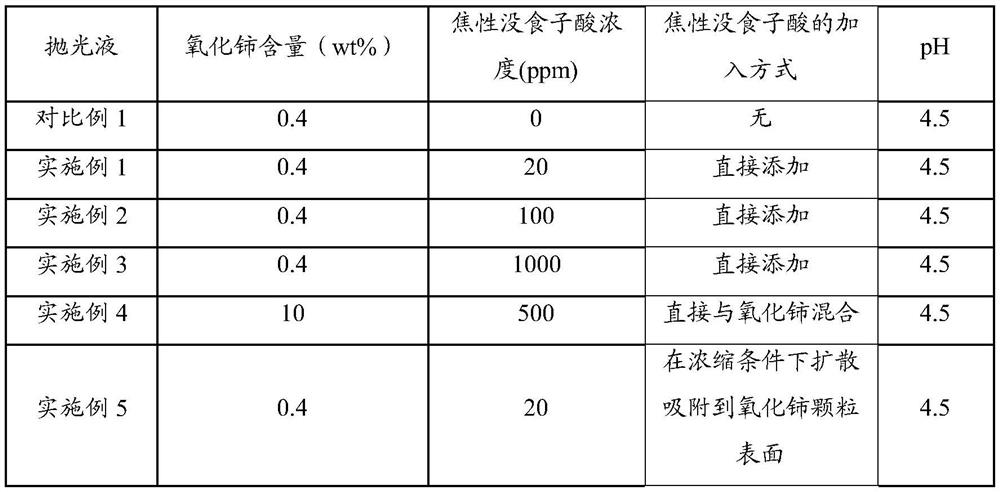

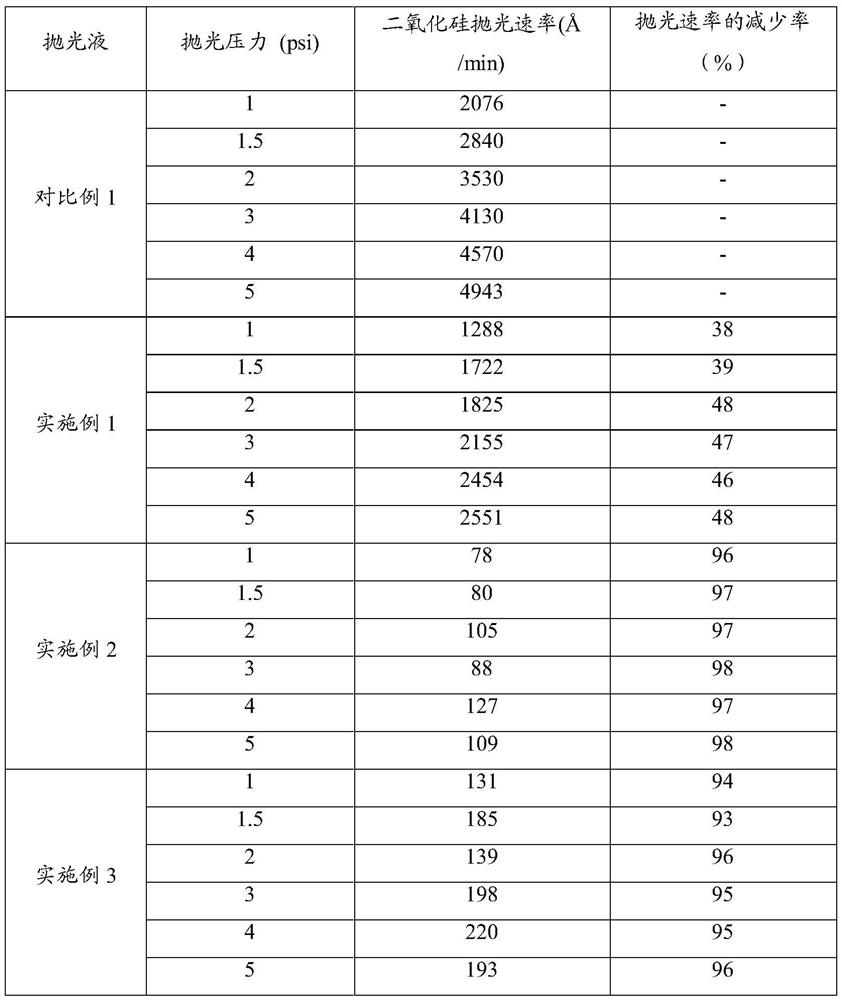

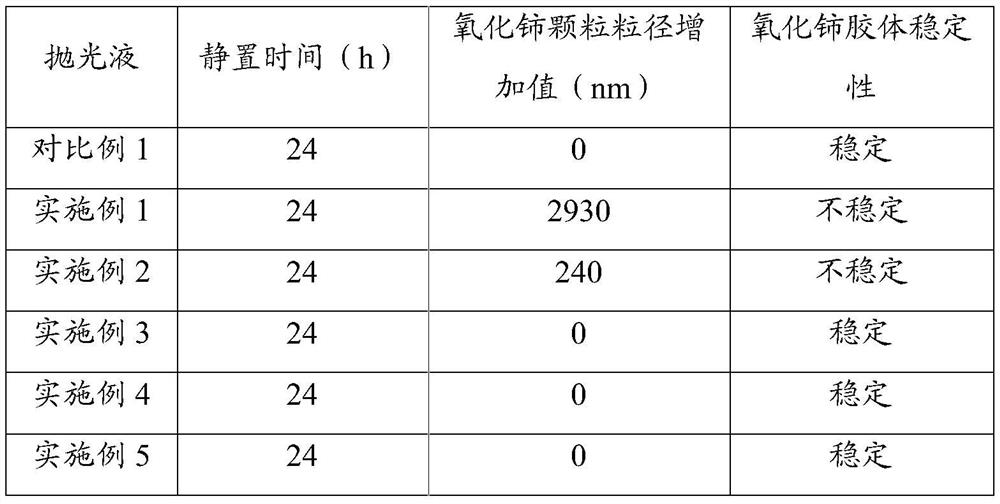

[0022] However, it can be seen from Examples 1-3 of the present invention that based on Comparative Example 1, the present invention adds pyrogallic acid to the polishing liquid, and the polishing rate of the polishing liquid on silicon dioxide is significantly inhibited. Only add 20ppm pyrogallic acid in the polishing liquid of embodiment 1, and the polishing rate of polishing liquid to silicon dioxide, under the polishing pressure of 1-5psi, has reduced about 35%-50% respectively, and polishing liquid is to silicon dioxide The polishing rate of silicon is reduced from high rate to medium rate. In embodiment 2, the content of pyrogallic acid is further increased to 100ppm, and the polishing rate of the polishing liquid to silicon dioxide is reduced by more than 95% under different polishing pressures, and the polishing rate of the polishing liquid to silicon dioxide is further reduced. to low rate; when embodiment 3 continued to increase the content of pyrogallic acid to 1000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com