Device for cooling silicon core drawing area during silicon core drawing

A technology of silicon core and cooling gas, which is applied in the direction of protecting fluid, crystal growth, single crystal growth, etc. It can solve the problems of silicon core scrapping, affecting the quality of silicon core, and unable to cool the plate valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples;

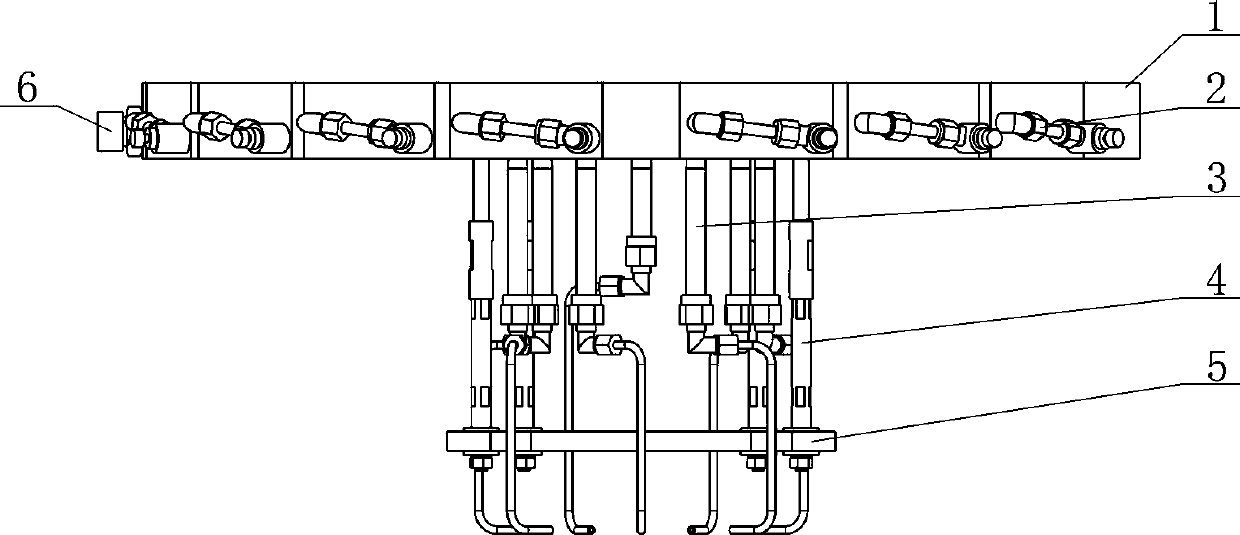

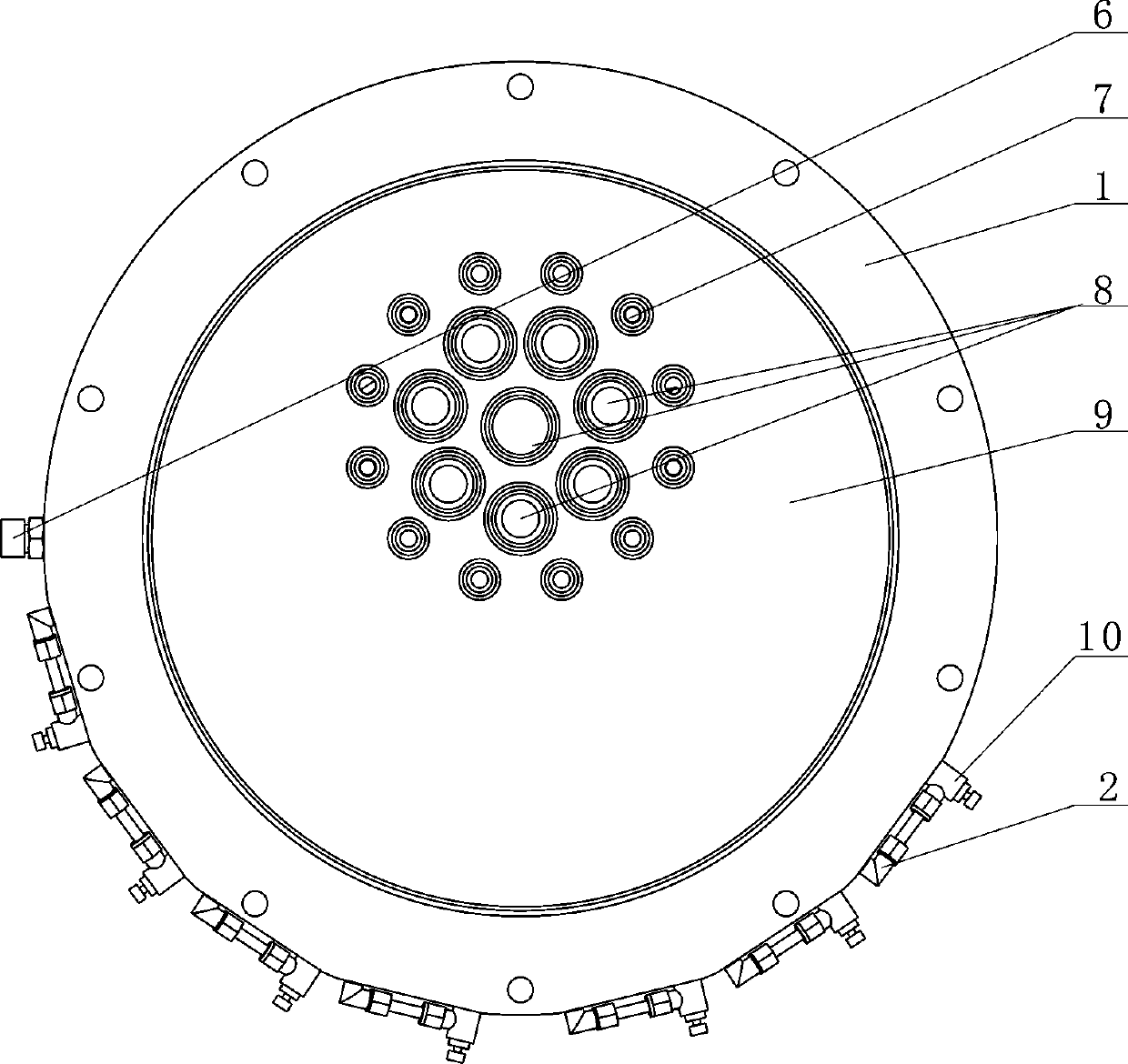

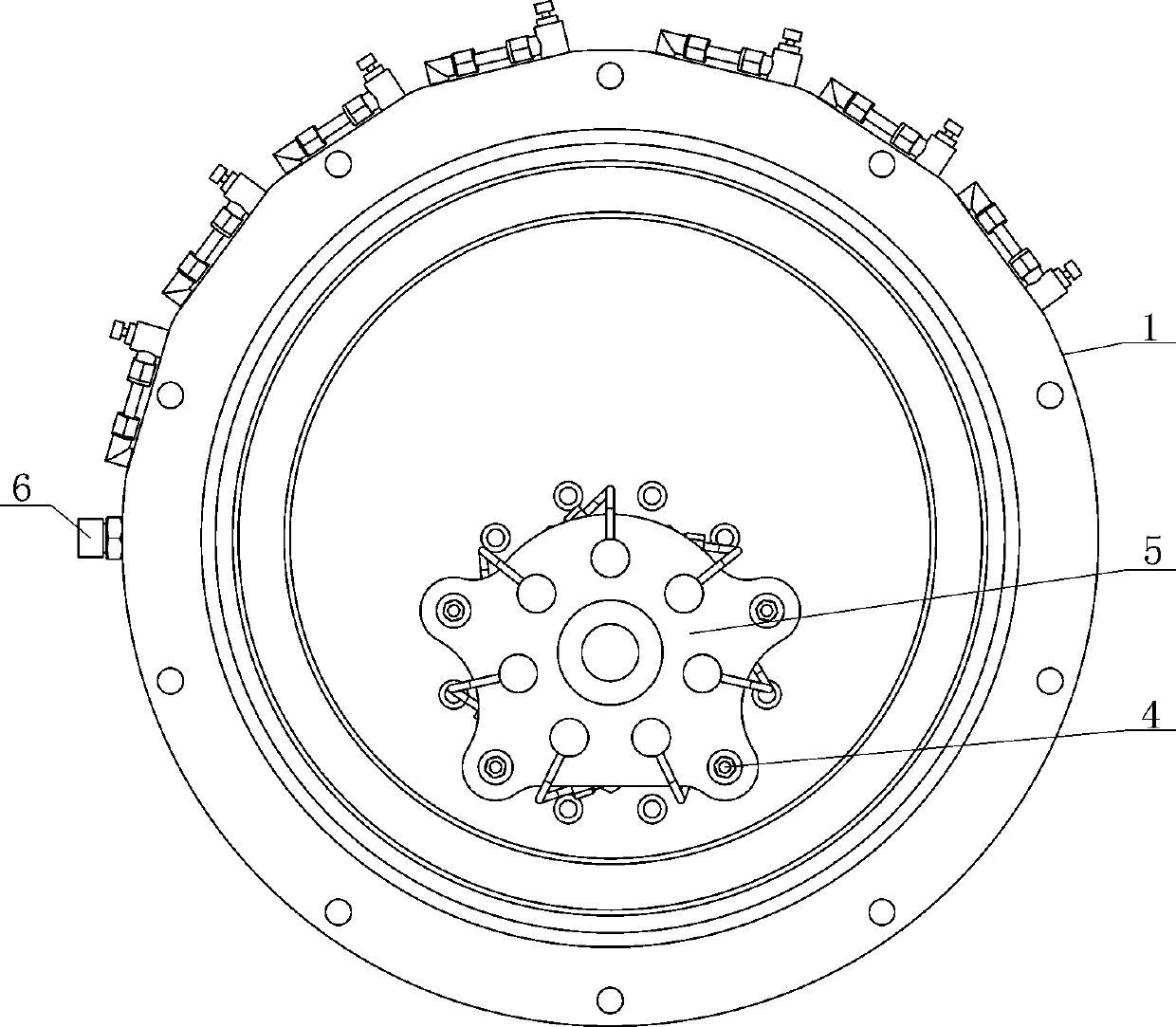

[0030] combined with Figure 1-7 A device for cooling the silicon core drawing area during silicon core drawing described in , comprising a plate body 1 and an air blowing pipe 3, and a downwardly recessed upper groove is provided on the top of the plate body 1 , the shape of the upper groove is a circular structure, and a plurality of silicon core perforated fixing columns extending upwards are arranged at intervals on the upper part of the bottom surface of the upper groove, and the layout of the plurality of silicon core perforated fixing columns is that a silicon core is arranged in the middle. core perforated fixing columns, and the rest of the silicon core perforated fixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com