Glutinous rice cake and preparation method thereof

A technology of glutinous rice cake and a main body is applied in the field of glutinous rice cake and its preparation, which can solve the problems of difficult production, unsuitable for industrial production, greasy taste and the like, and achieves the effects of avoiding mutual adhesion, avoiding singleness and crisp skin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

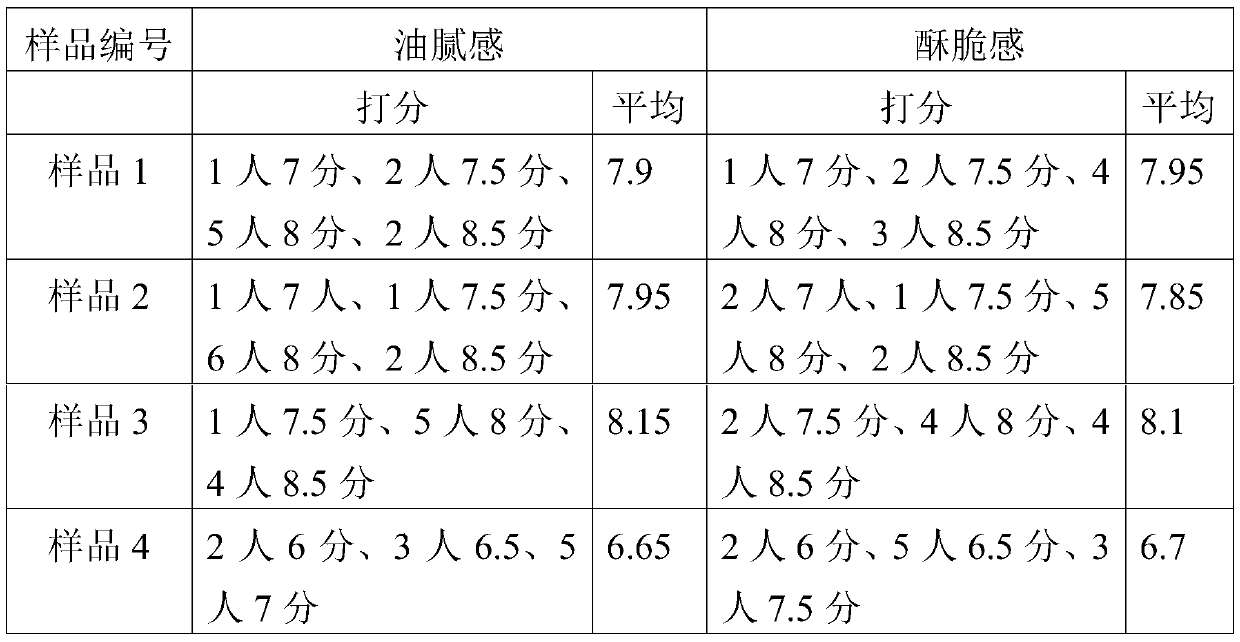

Embodiment 1

[0055] Weigh 30 parts of glutinous rice flour, 22 parts of drinking water, 4.3 parts of edible oil, 8 parts of white sugar, 4 parts of glutinous rice wine, 32 parts of compound stabilizer, and 1.28 parts of rice flour according to the ingredients. After 20 minutes, the dough was added into a forming machine to form a strip, and then the outer surface of the strip-shaped glutinous rice cake was wrapped with bread crumbs, and put into the quick-freezer for quick freezing at -18°C for 10 minutes to finalize the shape, and the glutinous rice cake was obtained, which was recorded as sample 1.

Embodiment 2

[0057] Weigh 60 parts of glutinous rice flour, 45 parts of drinking water, 8.6 parts of edible oil, 15 parts of white granulated sugar, 8 parts of glutinous rice wine, 45 parts of compound stabilizer, and 5.8 parts of rice flour according to the ingredients, add them into the dough mixer and stir at room temperature After kneading for 20 minutes, put the dough into the forming machine and form it into strips, then wrap the outer surface of the strip-shaped glutinous rice cakes with bread crumbs, put them into the quick-freezer for quick freezing at -18°C for 10 minutes to finalize the shape, and obtain the glutinous rice cakes, which are recorded as sample 2.

[0058] Washing the soybeans with drinking water, draining the water, frying the soybeans at an oil temperature of 60°C-80°C until they are crispy, cooling them in the air, crushing them, and sieving them to obtain the soybean powder.

[0059] When eating, directly take the deep-fried glutinous rice cake and dip it in soy...

Embodiment 3

[0062] Weigh 60 parts of glutinous rice flour, 45 parts of drinking water, 8.6 parts of edible oil, 15 parts of white sugar, 12 parts of glutinous rice wine, 45 parts of compound stabilizer, 1.58 parts of rice flour, 2 parts of black sesame, and add to the dough according to the ingredients. Stir and knead the dough in the machine at room temperature for 20 minutes, put the dough into the molding machine and shape it into strips, then put it into a container to wrap the outer surface with bread crumbs, put it in the quick freezer for 10 minutes at -18°C and freeze it for 10 minutes to get the glutinous rice cake, which is recorded as a sample 3.

[0063] Washing the soybeans with drinking water, draining the water, frying the soybeans at an oil temperature of 60°C-80°C until they are crispy, cooling them in the air, crushing them, and sieving them to obtain the soybean powder.

[0064] Add brown sugar into the pot, heat and stir at 100°C to make syrup, filter, fill to obtain b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com