A casting system and casting method with intelligent cooling function

A functional and intelligent technology, which is applied to casting equipment, manufacturing tools, and mold handling equipment, can solve the problems of casting falling, inconvenient fixed operation, and affecting the safety of surrounding personnel, etc., and achieve the effect of reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following content describes the specific implementation manner of the present invention in detail in conjunction with the accompanying drawings.

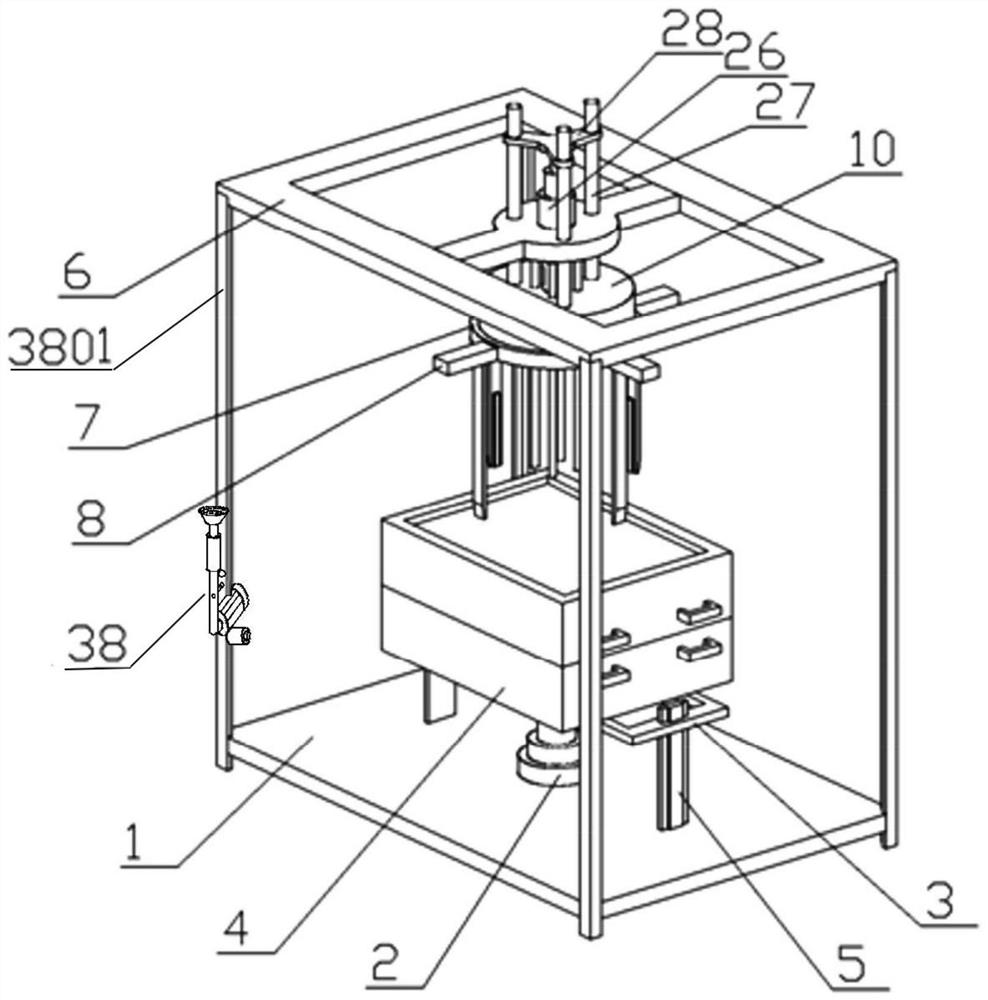

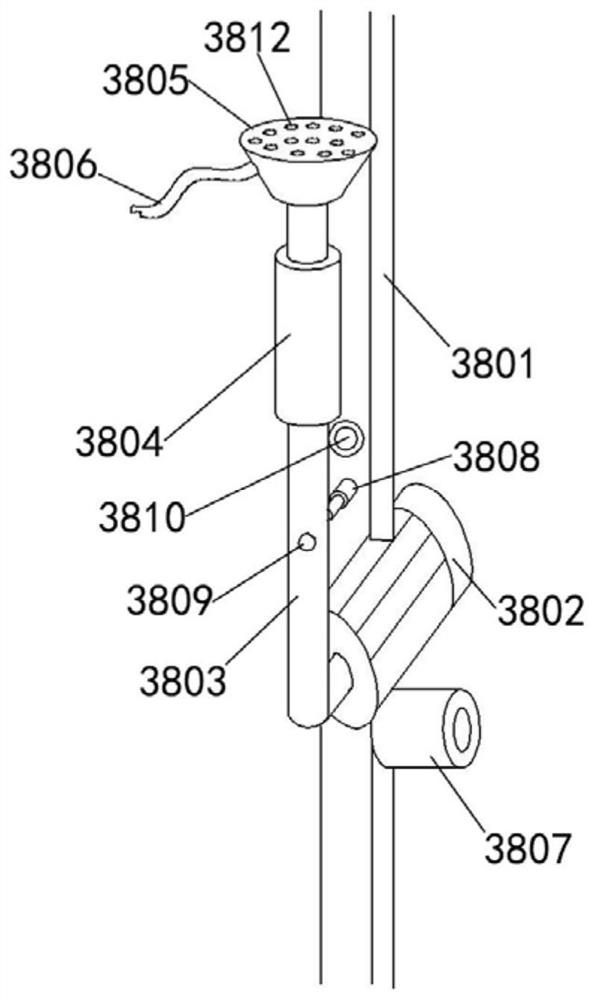

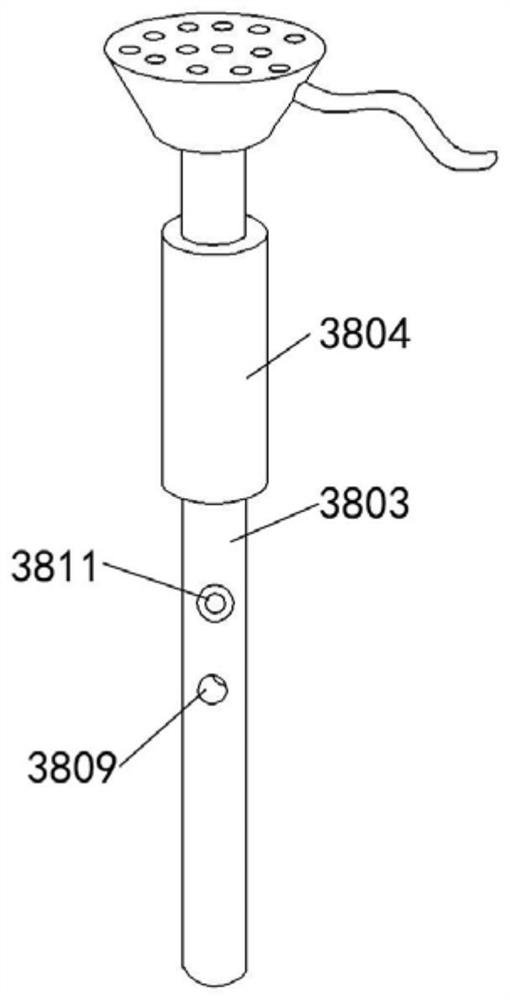

[0024] see Figure 1-10 A casting system with intelligent cooling function is shown, including the base body 1, the casting mold box 4 hydraulic rod I2, the hydraulic rod II26 and the drive motor 37, the base body 1 is provided with the hydraulic rod I2, and the upper side of the hydraulic rod I2 A bracket I3 is provided, and the upper side of the bracket I3 is provided with a molded box 4, the molded box 4 includes an upper box and a lower box, and the left and right sides of the hydraulic rod I2 are provided with a support rod I5, and the upper end of the support rod I5 penetrates and engages in the On the bracket I3, the upper end of the base body 1 is connected with a bracket II6. Also includes a cooling component 38, the cooling component 38 includes a positioning motor 3802 embedded in the column 3801, the output s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com