A welding machine for mask ear loops

A technology for welding machines and earbands, which is applied to sewing tools, protective clothing, and other household appliances, etc. It can solve the problems of low welding efficiency of earbands, complicated earband shearing mechanism, and large mechanism size, etc., and achieves reduction Moving action, high synchronization, and the effect of increasing the feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

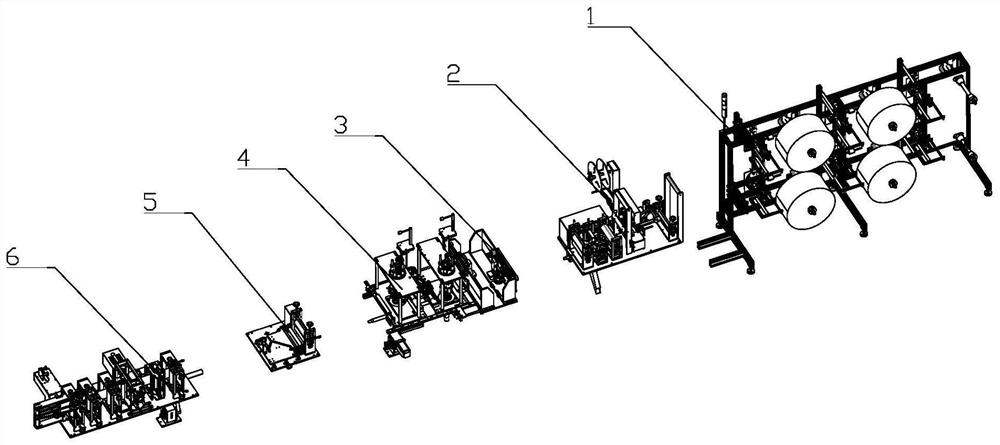

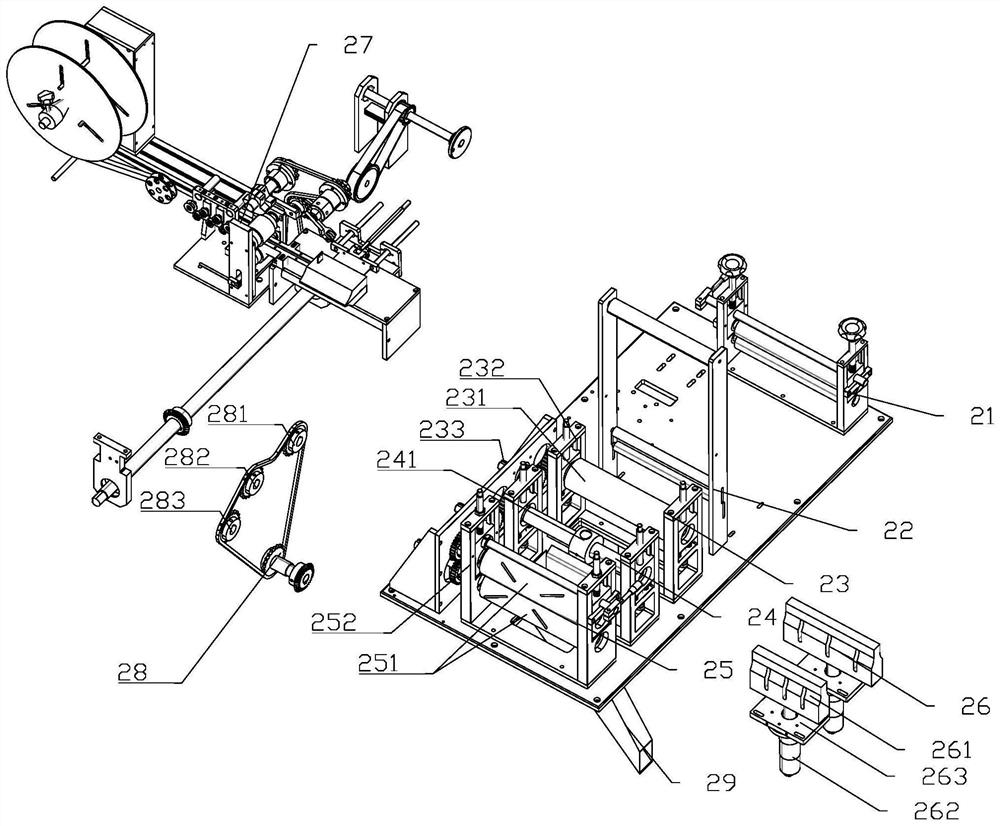

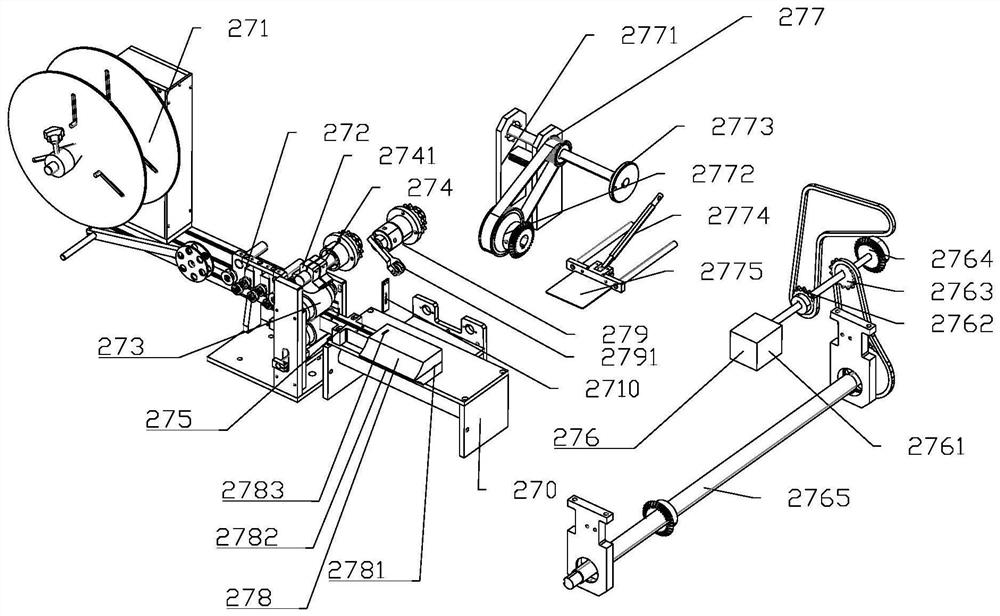

[0034] Such as figure 1 As shown, a fully automatic mask production system includes a cloth feeding device 1, a welding device 2, a pad printing device 3, a mask earband welding machine 4, a creasing device 5 and a die-cutting setting device 6; along the direction of processing, all The above-mentioned cloth feeding device 1, welding device 2, pad printing device 3, mask earband welding machine 4, creasing device 5 and die-cutting and shaping device 6 are successively connected.

[0035] The cloth feeding device 1 is used to convey the cloths of various materials, and the welding device 2 is used to weld the multi-layer cloths together and weld the nose strips on the mask surface; the pad printing The device 3 is used to print corresponding patterns on the mask surface; the mask ear strap welding machine 4 is used to weld two ear straps on both sides of the mask, and the creasing device 5 is used to crimp the mask, The die-cutting and shaping device 6 is used for shaping and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com