A high-precision material receiving device and method

A material receiving device and accurate technology, which is applied in the direction of packaging material feeding device, packaging, transportation packaging, etc., can solve the problems of rising labor costs, increased labor costs, and inability to increase production capacity, etc., and achieve faster switching speed and saving Labor cost, the effect of avoiding wastage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing.

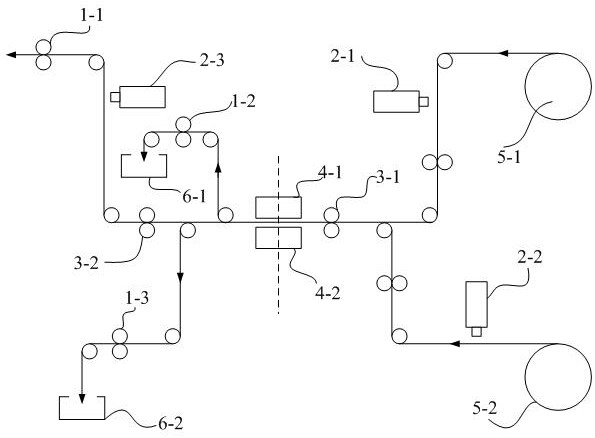

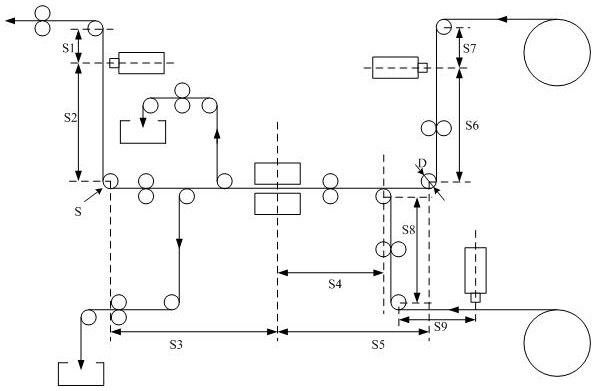

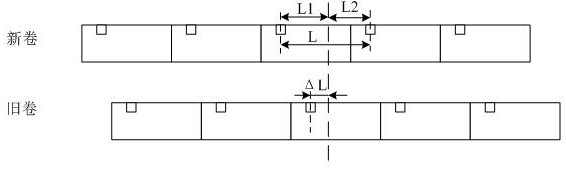

[0040] Such as figure 1 As shown, this embodiment includes material rolls 5-1, 5-2, three photoelectric positioning sensors 2-1, 2-2, 2-3, front pressure roller pair 3-1, rear pressure roller pair 3- 2. Cutting and pasting mechanism 4-1, 4-2, traction servo motor 1-1, 1-2, 1-3, material receiver 6-1, 6-2.

[0041] The new material of the new material roll passes through the first photoelectric positioning sensor 2-1 or 2-2, the front pressure roller pair 3-1, the cutting and pasting mechanism 4-1, 4-2, and then receives the material on the new material roll. Feeder 6-1 or 6-2.

[0042] The old material of the old material roll is connected to the subsequent In the station, there is a material redundancy mechanism in the follow-up station, so that when the traction servo motor 1-1 is suspended, the follow-up station can operate normally when the machine does not stop.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com