Efficient and economic airlift type self-circulation granular sludge bed nitrogen removal reactor and method

A granular sludge and reactor technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve problems such as unfavorable sludge separation and sedimentation, sludge running, etc., to strengthen the ability of sludge-water separation , improve stability, improve the effect of volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

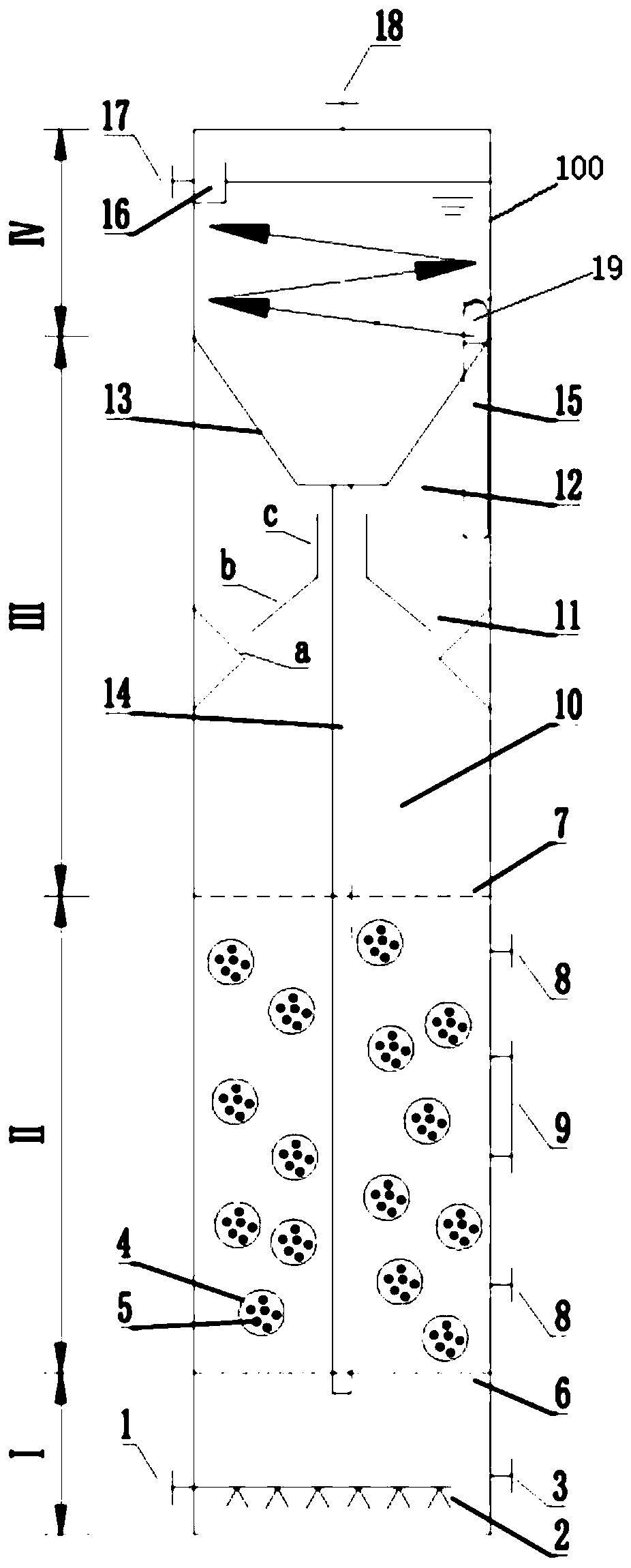

[0023] Please refer to figure 1 , the present embodiment is a high-efficiency and economical air-lift self-circulating granular sludge bed denitrification reactor, which includes a reactor body 100 forming a closed cavity structure, and water inlets arranged sequentially along the reactor body 100 from bottom to top. Water distribution area I, biological reaction area II, three-phase separation area III and cyclone separation area IV, the bottom of water inlet water distribution area I is closed, the top of said cyclone separation area IV is closed, water inlet water distribution area I, biological reaction The height ratio of zone II, three-phase separation zone III and cyclone separation zone IV is 1: (5~9): (2~5): (2~3), and they are connected in sequence to form the reactor body 100 .

[0024] The water inlet and water distribution area I is located at the bottom of the reactor, and mainly includes the water inlet 1 on one side, the water distribution pipe 2 connected with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com