Autotrophic nitrogen removal device for high-ammonia nitrogen

A technology of autotrophic denitrification and high ammonia nitrogen, applied in water treatment parameter control, sustainable biological treatment, water pollutants, etc. The effect of increasing system biomass, reducing system biomass loss and improving system denitrification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

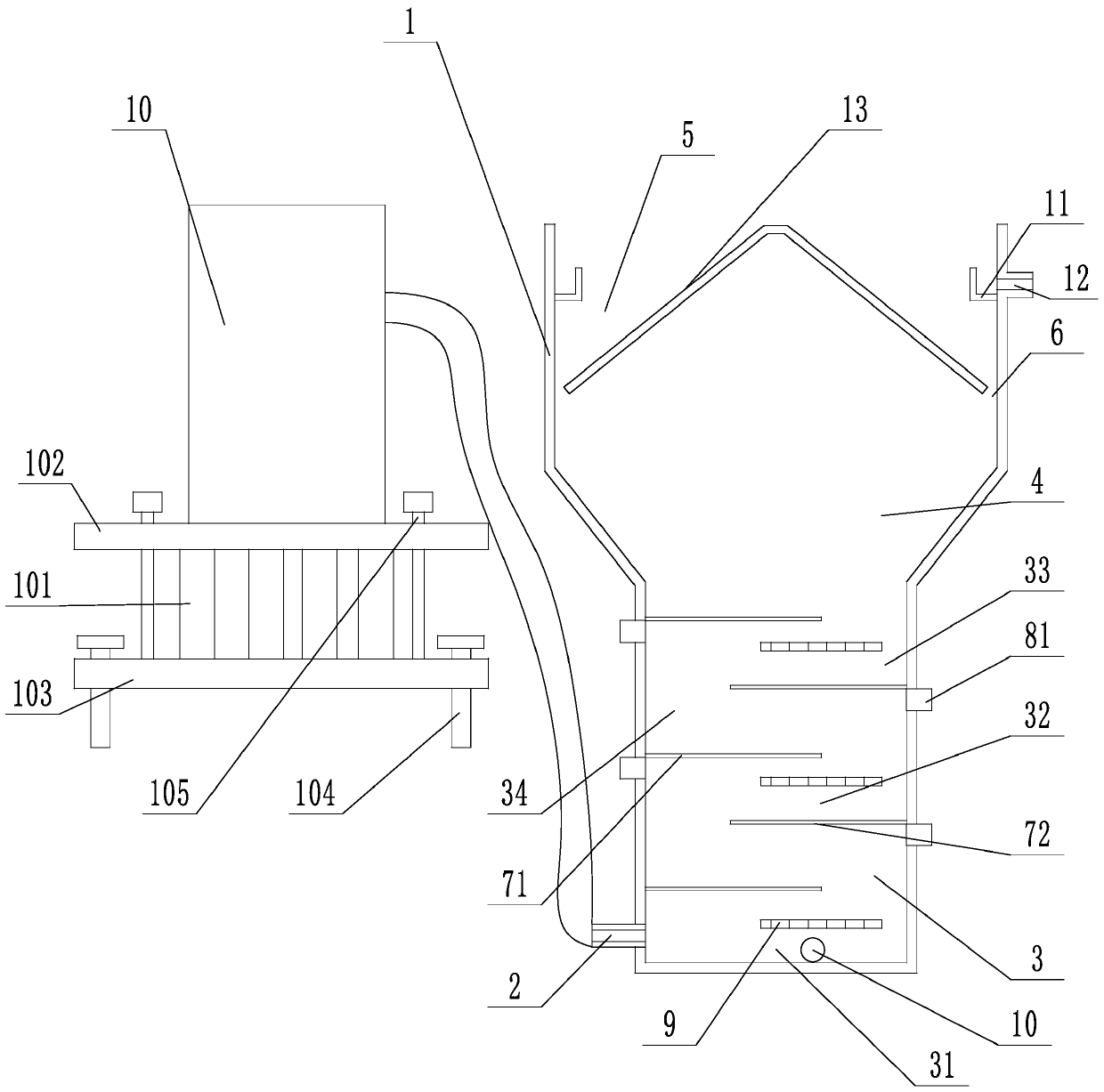

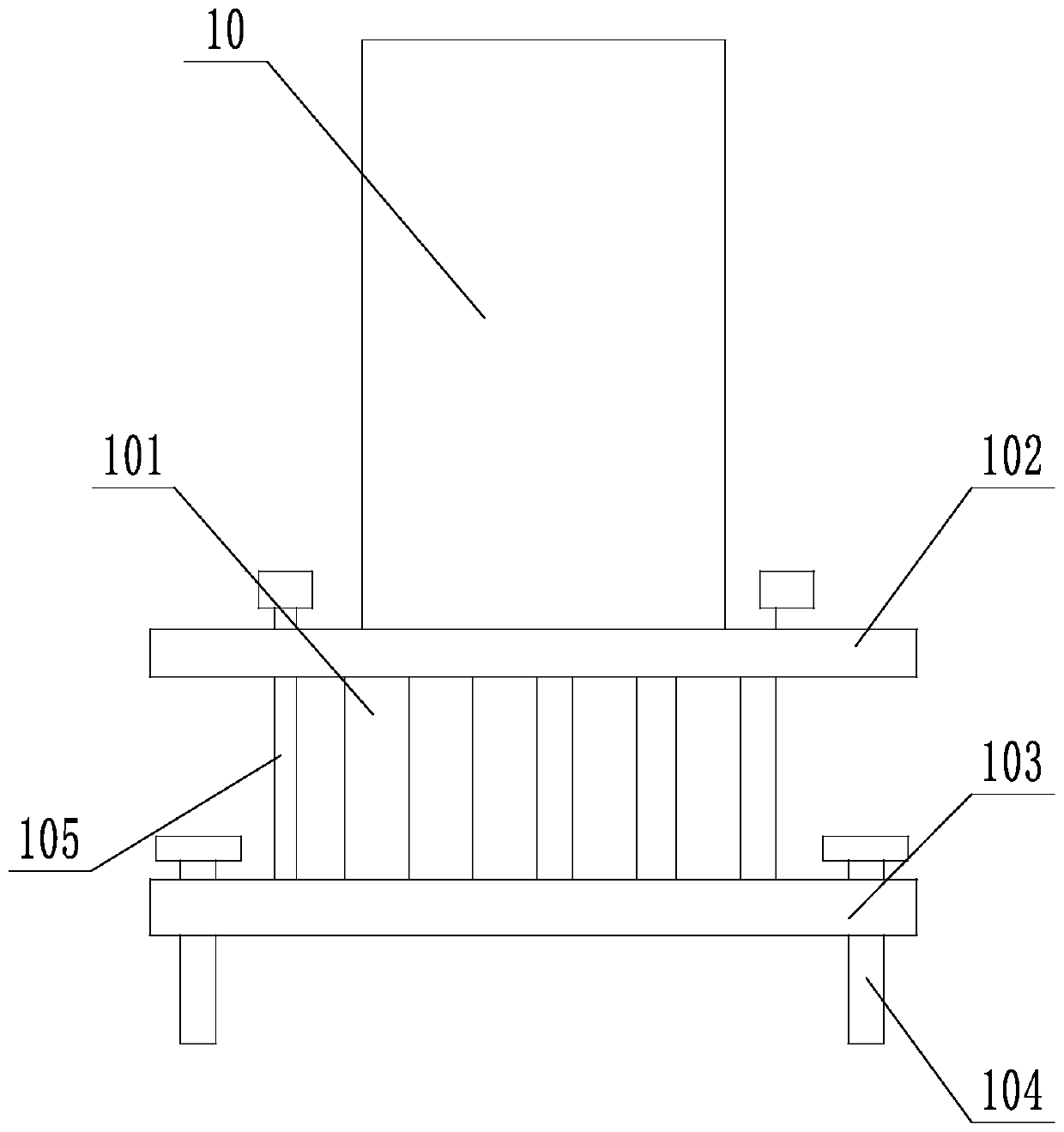

[0032] A high ammonia nitrogen autotrophic denitrification device, such as figure 1 As shown, the reaction device body 1 is included, and the reaction device body 1 includes the reaction zone 3, the precipitation zone 4, and the gas outlet zone 5 from bottom to top: the reaction zone includes aeration chambers formed by a number of semi-open deflectors and partitions , the fixed ends of the deflector and the partition are relatively arranged on the inner wall of the reaction device body 1, the deflector 71 and the partition 72 are arranged at intervals, and an aeration tube 9 is arranged in the aeration chamber on one side of the partition, A water inlet 2 for water intake is provided at the bottom of the reaction zone; a three-phase separator 13 is provided between the sedimentation zone 4 and the gas outlet zone 5, and the three-phase separator 13 is two mudguards inclined downward, and the two mudguards The gap between the fenders and the gap between the fender and the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com