Device and method for pretreating phosphogypsum by using magnesium hydroxide

A technology of magnesium hydroxide and a treatment method, which is applied in the application field of phosphogypsum, can solve the problems of poor cleaning effect, low strength, and many cleaning times, and achieves the effects of simple and easy method, good operability, and reduction of times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

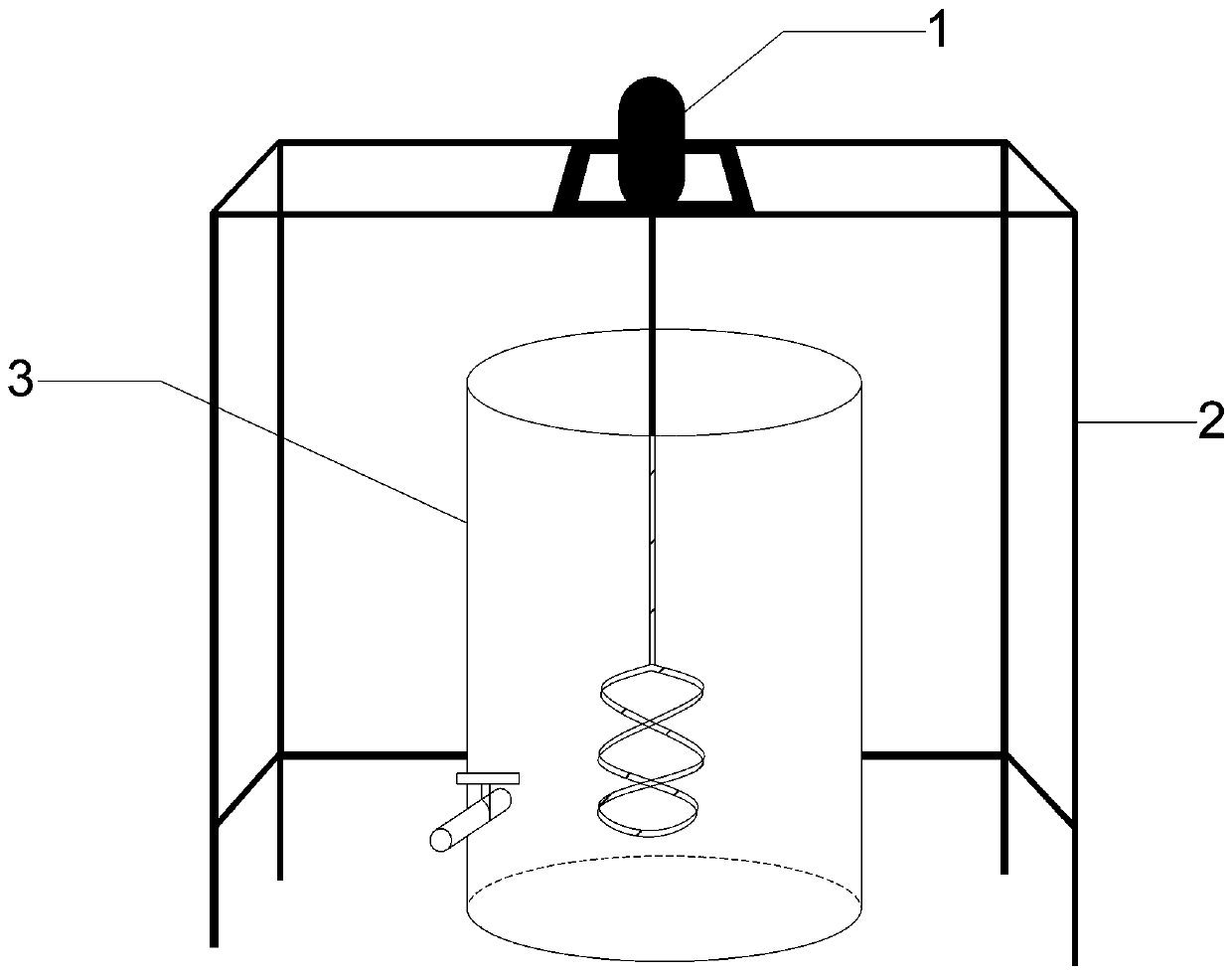

[0031] see figure 1 , a device for pretreating phosphogypsum with magnesium hydroxide, which includes a mixing bucket support frame 2, the top support of the mixing bucket support frame 2 is equipped with an agitator 1, and the bottom of the agitator 1 is provided with a Mixing cylinder 3 for materials to be processed. By adopting the device with the above structure, it can be used for preliminary cleaning treatment of phosphogypsum.

[0032] Further, the mixing cylinder 3 is provided with a valve. Through the above-mentioned valve, the waste water generated in the treatment process can be conveniently discharged.

[0033] Further, the device also includes a portable pH meter for measuring pH value. The above-mentioned portable pH meter can be used to measure the pH value during the cleaning process.

Embodiment 2

[0035] The treatment method of the device of pretreatment phosphogypsum with magnesium hydroxide, it comprises the following steps:

[0036] Step 1: Fix the support frame 2 of the mixing tank, erect the agitator 1 on the top of the support frame 2 of the mixing tank, and extend the stirring blade of the agitator 1 into the inside of the mixing cylinder 3;

[0037] Step 2: Take a certain amount of phosphogypsum and pour it into the inside of the mixing cylinder 3, and pour water into the inside of the mixing cylinder 3 according to the ratio of phosphogypsum to water as A;

[0038] Step 3: start the agitator 1, and fully stir and mix the water and phosphogypsum inside the mixing cylinder 3 through the agitator 1;

[0039] Step 4: Pour the magnesium hydroxide powder whose total amount is 0.01%~0.05% of the phosphogypsum mass into the bucket, and make it fully mix with the phosphogypsum body;

[0040] Step 5: start the agitator 1, stir the phosphogypsum added with magnesium hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com