Building solid waste regenerated composite roadbed filler and preparation method thereof

A technology of composite roadbed and roadbed filler, applied in the field of roadbed filling, can solve the problems of shortage of natural fillers, occupying land, polluting the environment, etc., and achieve the effects of controlling costs, reducing construction costs, and alleviating resource shortages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

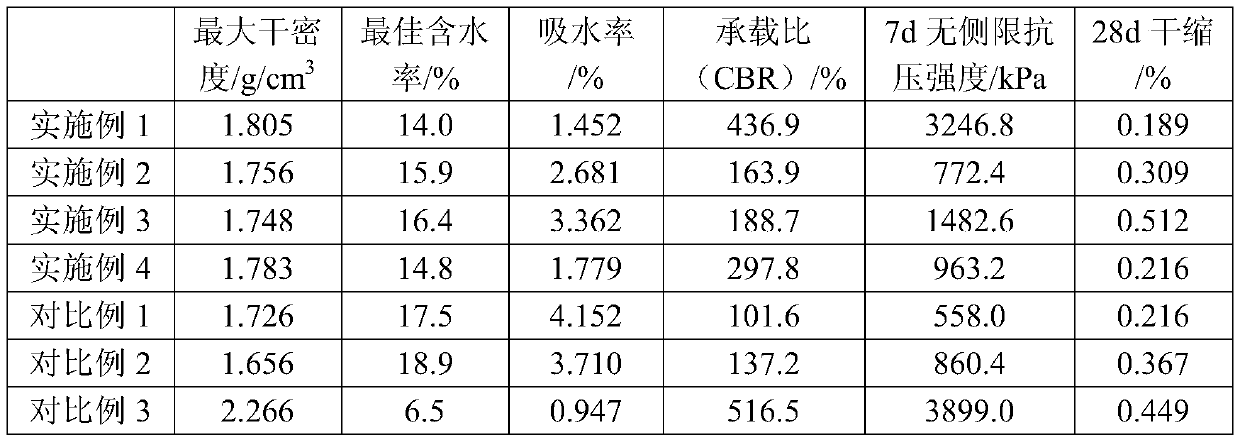

Examples

Embodiment 1

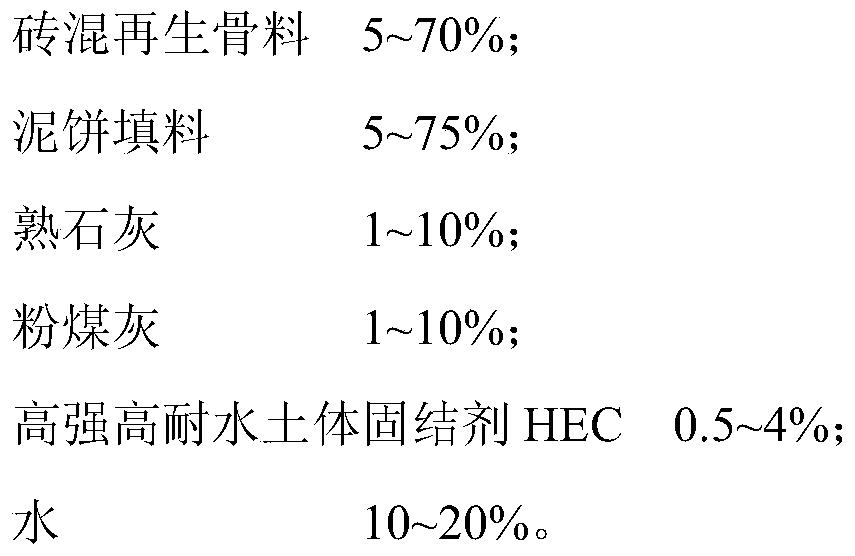

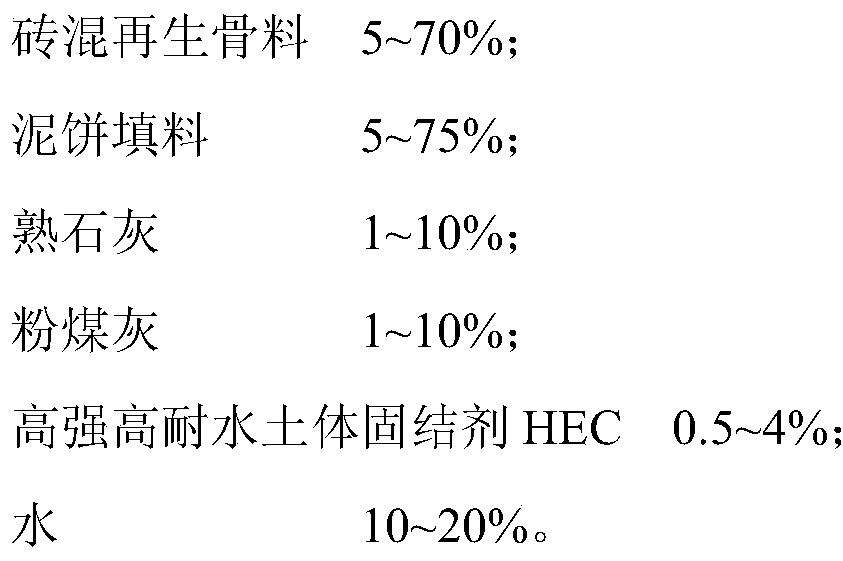

[0030] The construction solid waste recycled composite subgrade filler is composed of the following materials by mass percentage: 66.2% of brick-concrete recycled aggregate, 7.4% of mud cake filler, 1.8% of grade II calcareous slaked lime, 8.8% of grade II fly ash, 3.5% of HEC, water 12.3%; the mass percentage of water is determined through heavy-duty compaction tests according to the standard JTG E40-2007 "Highway Soil Test Regulations", the same below.

Embodiment 2

[0032] Construction solid waste recycled composite subgrade filler is composed of the following materials by mass percentage: brick-concrete recycled aggregate 22.0%, mud cake filler 51.4%, grade II calcareous slaked lime 4.3%, grade II fly ash 8.1%, HEC 0.5%, water 13.7%.

Embodiment 3

[0034] The construction solid waste recycling composite subgrade filler is composed of the following materials by mass percentage: 7.8% of brick-concrete recycled aggregate, 70.3% of mud cake filler, 1% of grade II calcareous slaked lime, 4.2% of grade II fly ash, 2.6% of HEC, water 14.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com