Carbon dioxide response type intelligent gel channeling sealing agent and preparation method and application thereof

An intelligent gel sealing agent and intelligent gel sealing technology are applied in the field of wellbore sealing to achieve the effects of low viscosity, strong fluidity and good injectability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

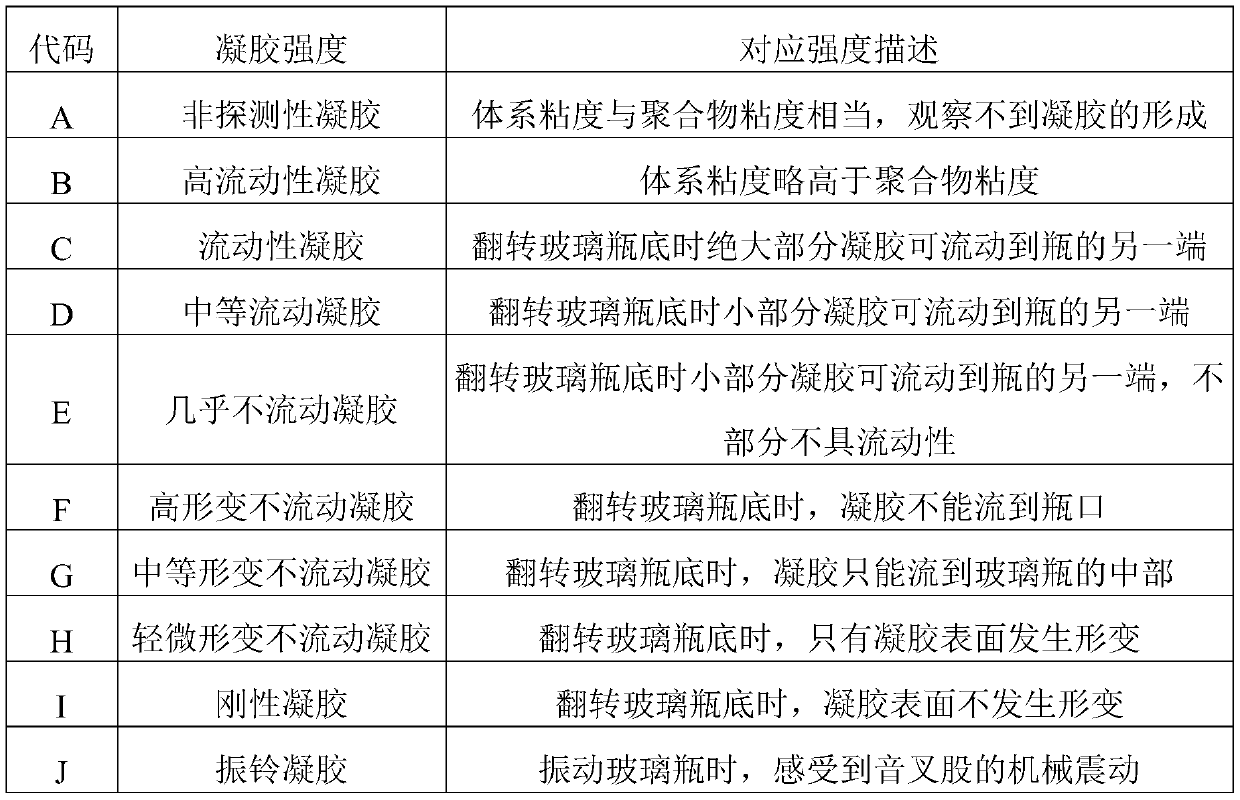

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a CO 2 Responsive smart gel channeling agent, which is prepared through the following steps:

[0032] Dissolve polyacrylamide, xanthan gum, and cationic starch with a degree of hydrolysis of 30% in deionized water to form three solutions with a weight concentration of 0.5%, 0.5%, and 0.5%, respectively. Take a certain amount of each solution and place it in the reaction Stir uniformly in the device, and simultaneously feed nitrogen into the system to remove oxygen for 30 minutes. While stirring, slowly add aluminum citrate and nanoclay with a mass concentration of 1.5% to the system successively (3 drops / second), and then Stir for more than 120 minutes, put the reactor into a 60°C constant temperature water bath, pass nitrogen into the reactor to remove oxygen, and when the temperature of the aqueous solution in the reactor reaches 60°C, continue to stir for more than 120 minutes to obtain a water-soluble sol.

[0033] Continuously inject CO in...

Embodiment 2

[0040] This embodiment provides a CO 2Responsive smart gel channeling agent, which is prepared through the following steps:

[0041] Dissolve polyacrylamide, xanthan gum, and cationic starch with a degree of hydrolysis of 30% in deionized water to form three solutions with a mass concentration of 1.5%, 1.5%, and 1.5%, and each take a certain amount of solution and place it in the reactor Stir uniformly inside the system, and at the same time pass nitrogen to the system to remove oxygen for 30 minutes. While stirring, slowly add aluminum citrate and nanoclay with a mass concentration of 1.5% respectively (4 drops / second) into the system successively, and then stir After more than 120 minutes, put the reactor into a constant temperature water bath at 60°C, pass nitrogen into the reactor to remove oxygen, and when the temperature of the aqueous solution in the reactor reaches 60°C, continue to stir for more than 120 minutes to obtain a water-soluble sol. Continuously inject CO i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com