Device for reducing spring rate of backfilled and sprayed concrete

A rebound rate, No. 1 technology, applied in the field of rebound rate devices, can solve the problems of waste, scattered in the tunnel, increased construction cost of injection concrete, etc., to achieve the effect of convenient disassembly and installation, and reduce the rebound rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

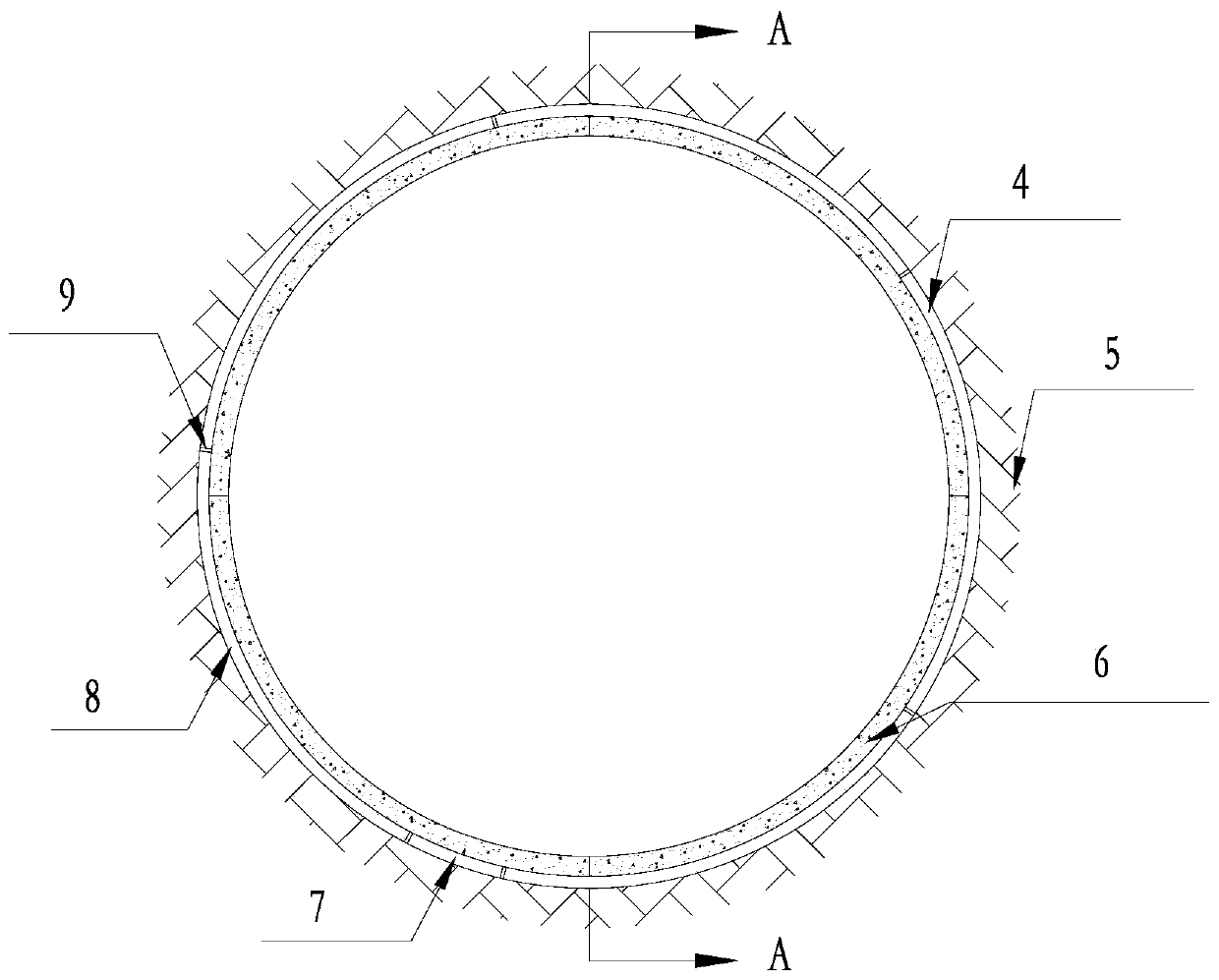

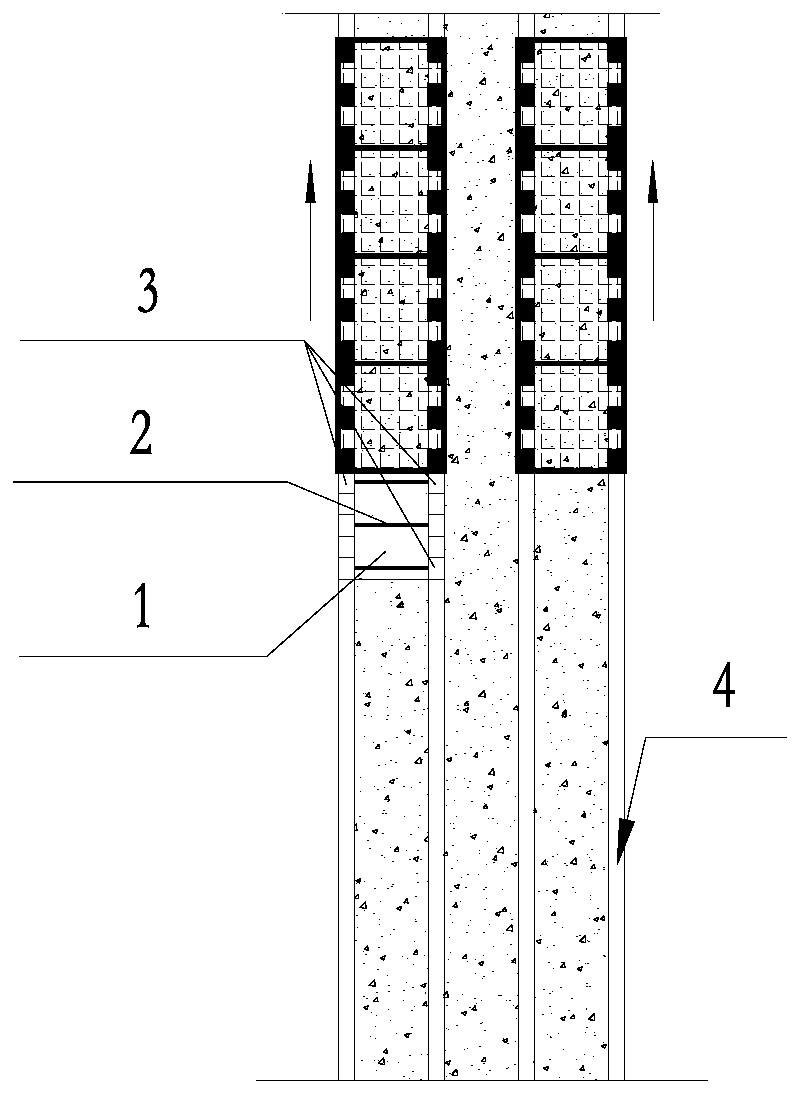

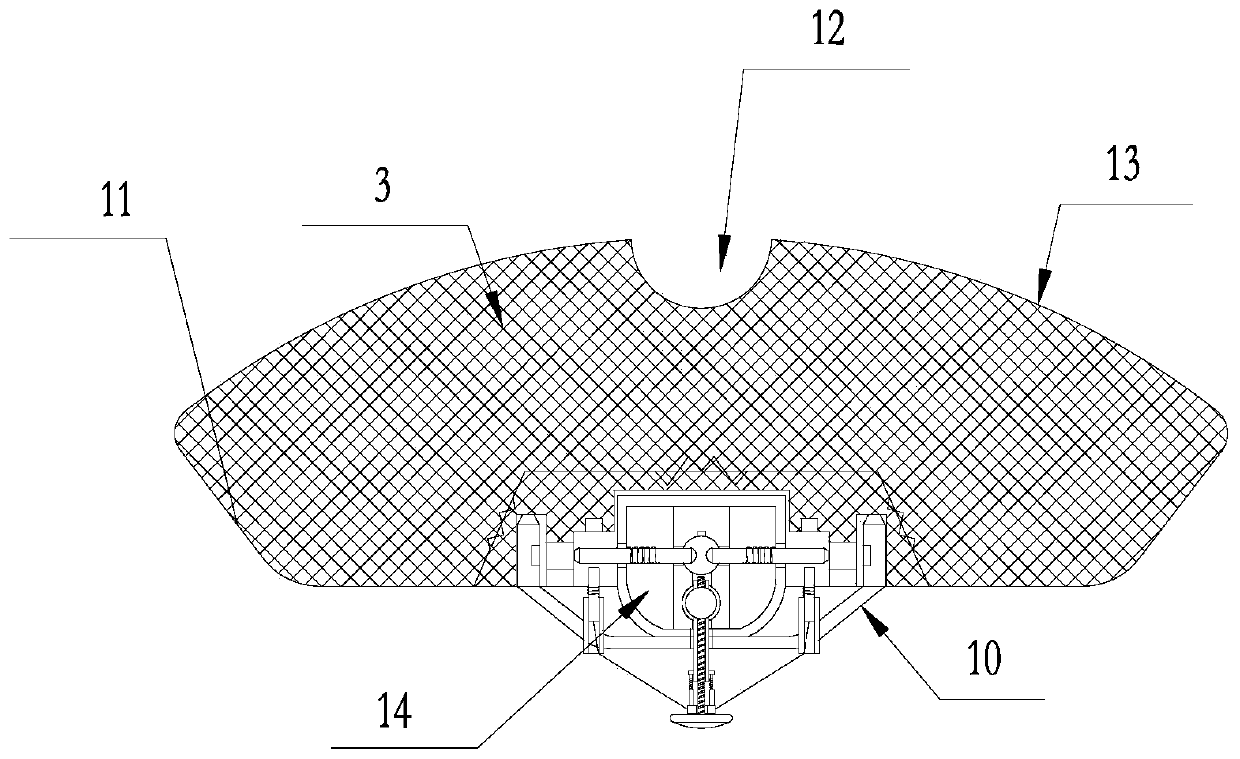

[0037] Attached below Figure 1-6 The present invention is further described with embodiment:

[0038] A device for reducing the rebound rate of backfilled sprayed concrete, including a steel arch 4, which is composed of a wedge-shaped block arch 7 and a standard block arch 8, and the wedge-shaped block arch 7 and the standard block arch 8 are placed between two The bolts 9 of the arch frame are connected, the steel arch frame 4 acts as a support for the surrounding rock of the tunnel 5, and the combination of the steel arch frame 4, the wedge block arch frame 7 and the standard block arch frame 8 is provided with a second liner of reinforced concrete 6 , the steel arch 4 is provided with a PVC endurance board 1, a crosspiece 2 and a powerful electromagnet 3, wherein the crosspiece 2 is provided with three pieces, the strong electromagnet 3 is provided with six pieces, and the crosspiece 2 is connected with the strong electromagnet 3 , and the PVC endurance board 1, the crosspi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com