Composite heat exchanging device with grooved convex spherical surfaces and fins distributed alternately

A technology of heat exchange device and convex spherical surface, applied in lighting and heating equipment, heat transfer modification, heat exchange equipment, etc., can solve the problems of high flow rate, high heat flux density, small size, etc., and achieve enhanced flow heat transfer ability, improving the convective heat transfer coefficient, and the effect of good longitudinal disturbance ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

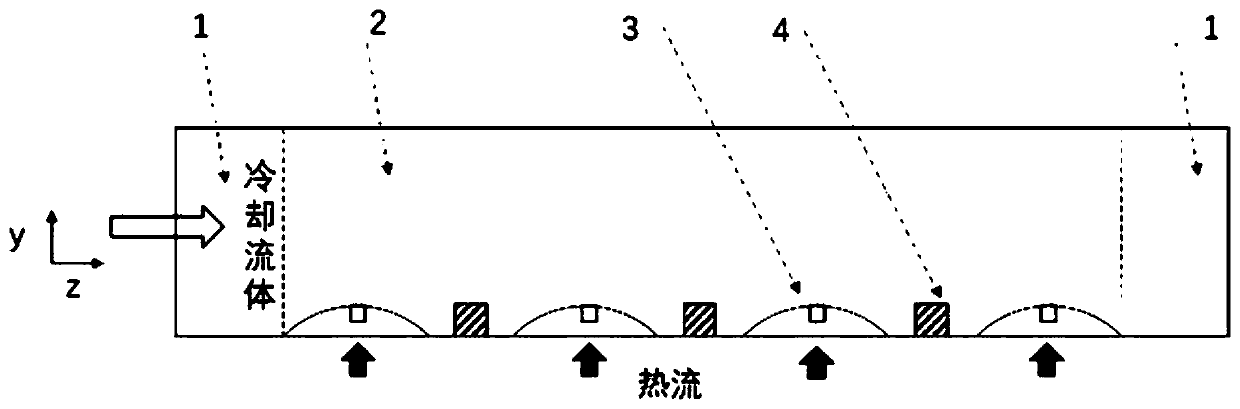

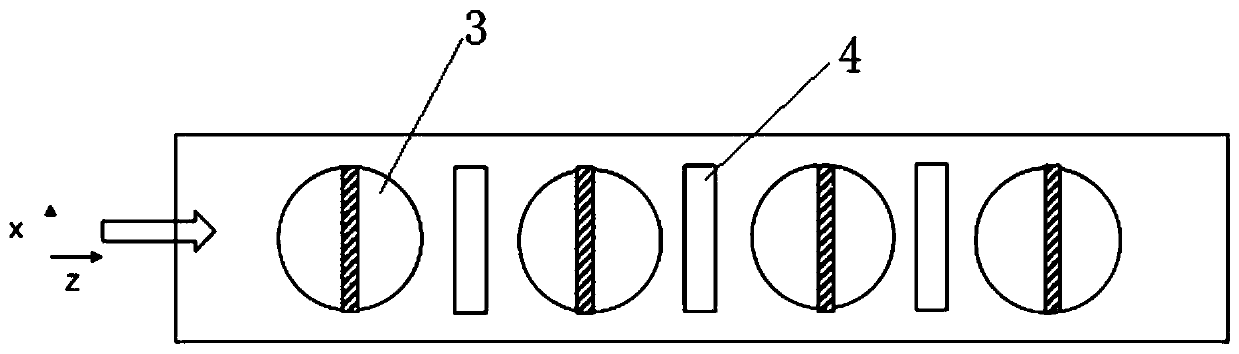

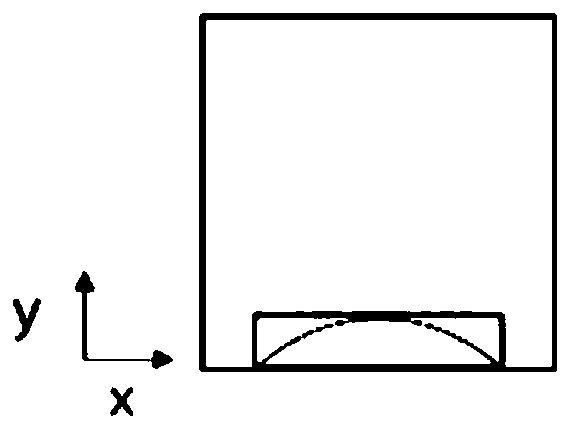

[0020] combine Figure 1-3 , a composite heat exchange device with grooved convex spherical surfaces and fins distributed in a distributed manner, including a plurality of convex spherical surfaces 3 and fins 4 arranged on the bottom surface of the cooling pipe, the plurality of convex spherical surfaces 3 and fins 4 Arranged at intervals in sequence, grooves are opened on the surface of the convex spherical surface 3 , the area where the convex spherical surface 3 and the fins 4 are provided is the flow disturbance area 2 , and the front and rear flow development area 1 .

[0021] Preferably, the opening direction of the groove is perpendicular to the flow direction of the fluid.

[0022] Preferably, the height of the convex spherical surface 3 is 10% of the equivalent diameter of the cooling pipe.

[0023] Preferably, the depth of the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com