Circuit board temperature distribution rapid test method based on small amount of measurement point data

A technology of temperature distribution and measuring point data, which is applied in the direction of electronic circuit testing, thermometers and thermometers using electric/magnetic elements that are directly sensitive to heat, and can solve problems such as low efficiency, large measurement errors, difficulty in measurement or large measurement errors, etc. problem, achieve the effect of reducing cost, improving test efficiency, and obtaining complete information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

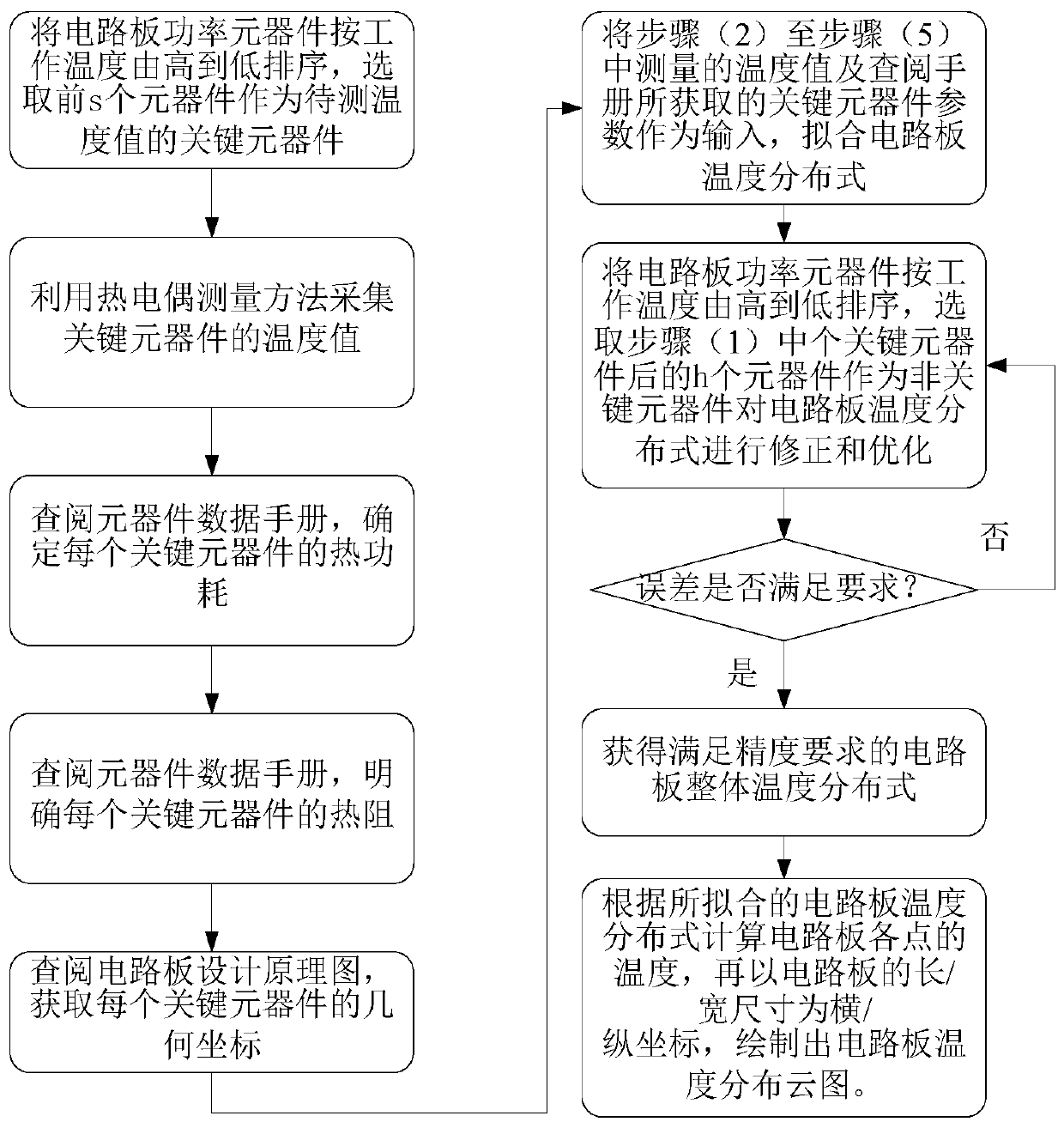

[0034] In order to make the features and advantages of the present invention more clearly understood, the following combination figure 1 The present invention is described in detail as follows:

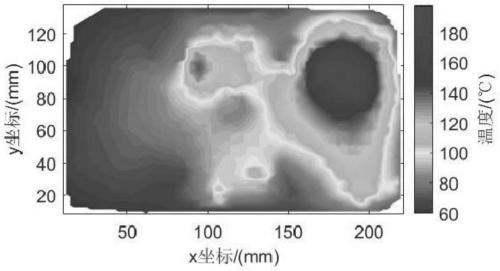

[0035] The specific implementation steps of a kind of circuit board temperature distribution rapid test method based on a small amount of measuring point data of the present invention are:

[0036] Step (1): Sort the circuit board components in descending order of operating temperature, and select the first s components as key components for the temperature value to be measured.

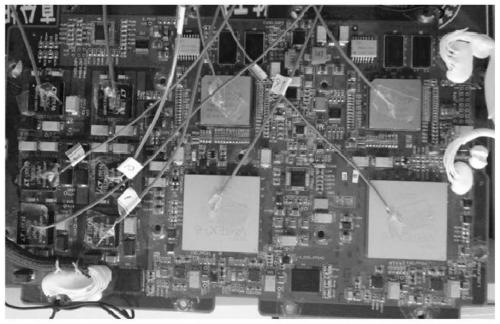

[0037] For the circuit board to be tested, considering the distribution of high-power and high-temperature components and the heat dissipation capability of the components, the components of the circuit board are sorted according to their operating temperature, and the first s components with higher temperature are selected as key components. In the example, the circuit board to be tested (such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com