Anti-shielding photovoltaic assembly with high system power generation efficiency

A technology of power generation efficiency and photovoltaic modules, which is applied in the field of high system power generation efficiency and anti-shading photovoltaic modules, can solve the problems of reduced power generation efficiency of modules, increased cell spacing, and difficult operation, so as to improve power generation efficiency, reduce quantity, and improve The effect of power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

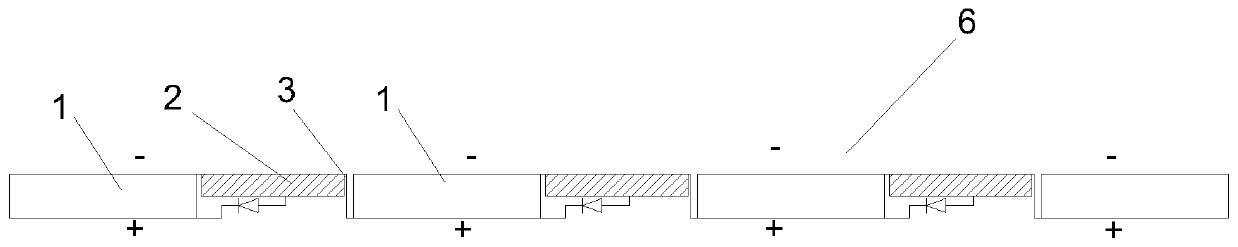

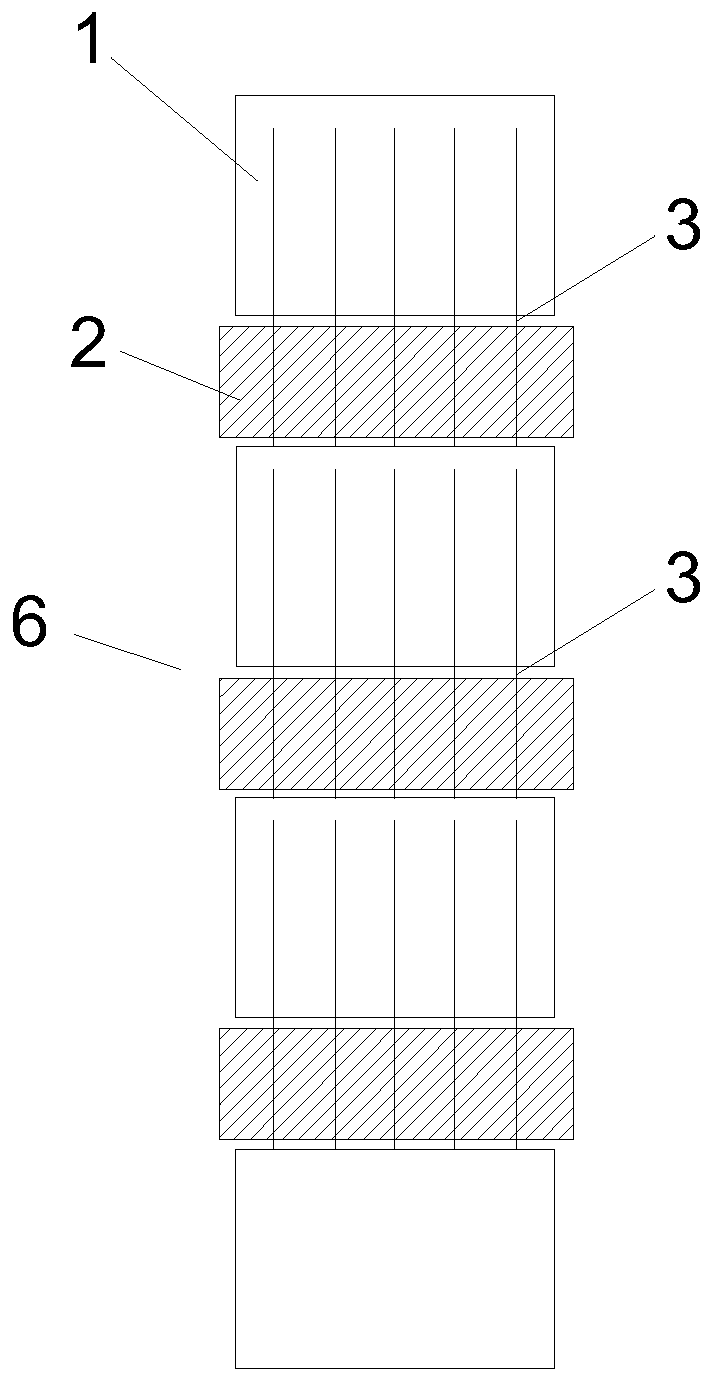

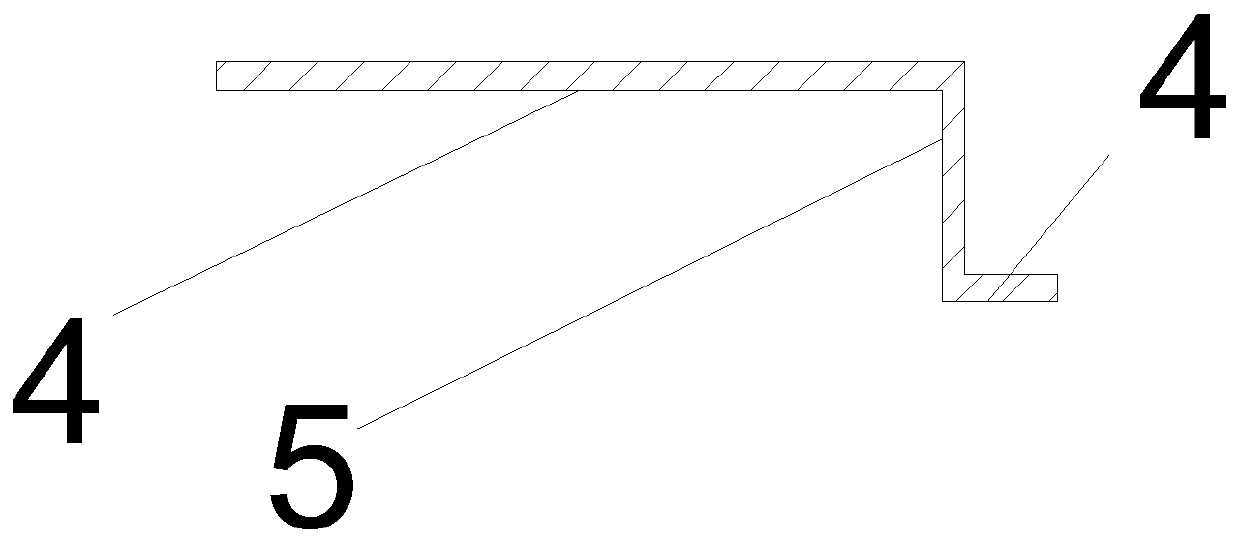

[0023] As shown in the figure, a string welding structure of solar cell components includes solar cell components, the solar cell components are composed of several strings of battery strings 6 arranged in matrix in series, and the battery strings 6 of several strings are composed of several battery sheets 1 in series, in the same string of battery strings 6, two adjacent battery pieces 1 are connected in series through interconnection bars 3, and a conductor 2 is provided in the gap between two adjacent battery pieces 1, and the The conductor 2 is electrically connected to the interconnection bar 3 located in the gap, the conductor 2 is provided with a light-reflecting structure, and each conductor 2 is provided with a diode 7 on the side facing away from the light. 7 is electrically connected with the battery sheet 1 . The interconnection bar 3 is composed of several wires, and the interconnection bar 3 connects several battery slices 1 in series. The upper surface of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com