Improved P-type PERC (Passivated Emitter Rear Contact) two-sided solar cell and preparation method thereof

A solar cell and an improved technology, applied in the field of solar cells, can solve problems such as high cost and complicated process, and achieve the effect of low equipment investment cost, simple preparation process, and suitable for wide promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

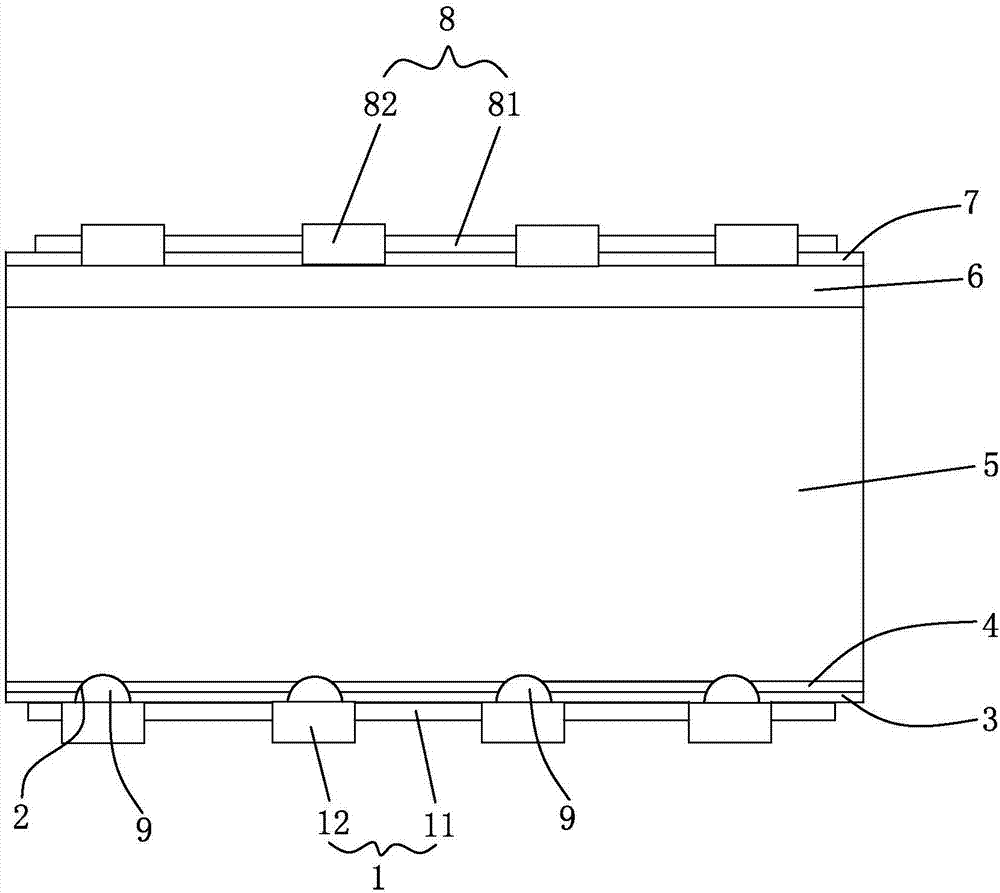

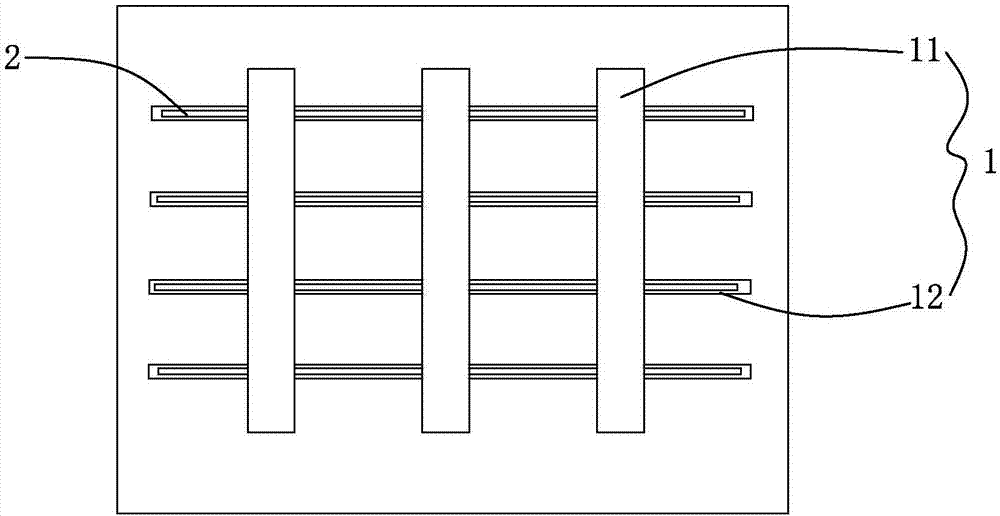

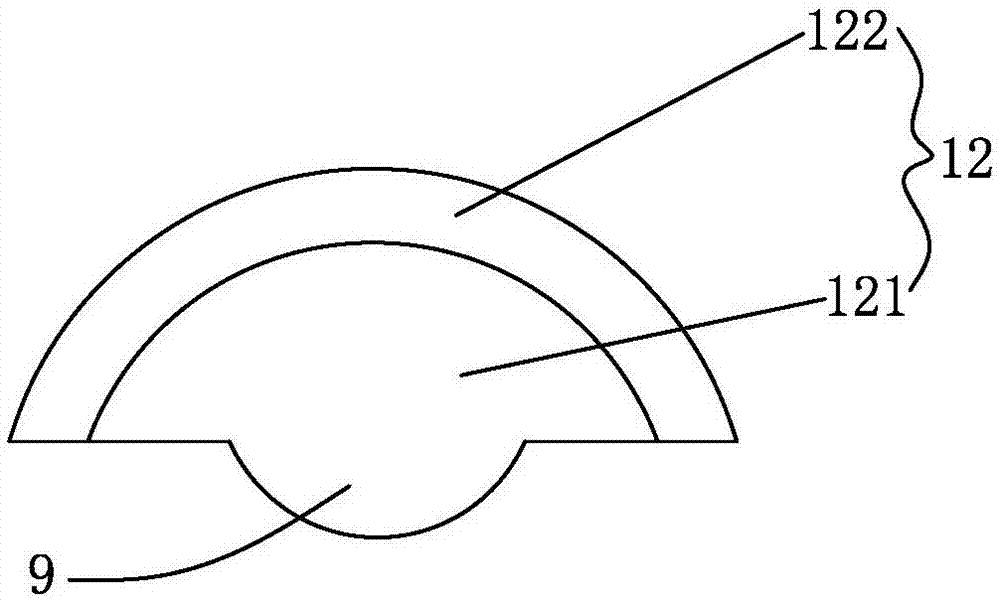

[0045] Such as Figure 1~3 As shown, it is an improved double-sided P-type PERC solar cell of the present invention, including a back electrode 1, a back silicon nitride film 3, an aluminum oxide film 4, a P-type silicon 5, and an N-type emitter arranged sequentially from bottom to top. 6. The front silicon nitride film 7 and the front silver electrode 8, the front silver electrode 8 is mainly formed by connecting the front silver electrode sub-grid 82 and the front silver electrode main grid 81 which are vertically intersecting. The back electrode 1 is mainly formed by connecting the back electrode main gate line 11 and the back electrode sub-gate line 12 which are vertically intersecting. On the back silicon nitride film 3, there is an opening through the back silicon nitride film 3 and the aluminum oxide film 4. Slot 2, P-type silicon 5 is exposed in slot 2, back electrode auxiliary grid line 12 is mainly composed of back aluminum grid line 121 and back silver grid line 122...

Embodiment 2

[0061] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that each group of slots 2 is vertically arranged and arranged in parallel, and the slots 2 and the back electrode sub-gate line 12 are perpendicular to each other. The part of the aluminum gate line 121 located in the slot is connected to the P-type silicon.

Embodiment 3

[0063] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that each group of slots 2 is composed of several rows of slots arranged in parallel in the transverse direction, and each row of slots is composed of several sections of slots arranged in parallel in the longitudinal direction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com