High-voltage cable deicing device based on ultrasonic deicing

A high-voltage cable, ultrasonic technology, applied in the installation of cables, electrical components, overhead installation, etc., to achieve low energy consumption, solve the power failure of the cable, and offset the effect of its own shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

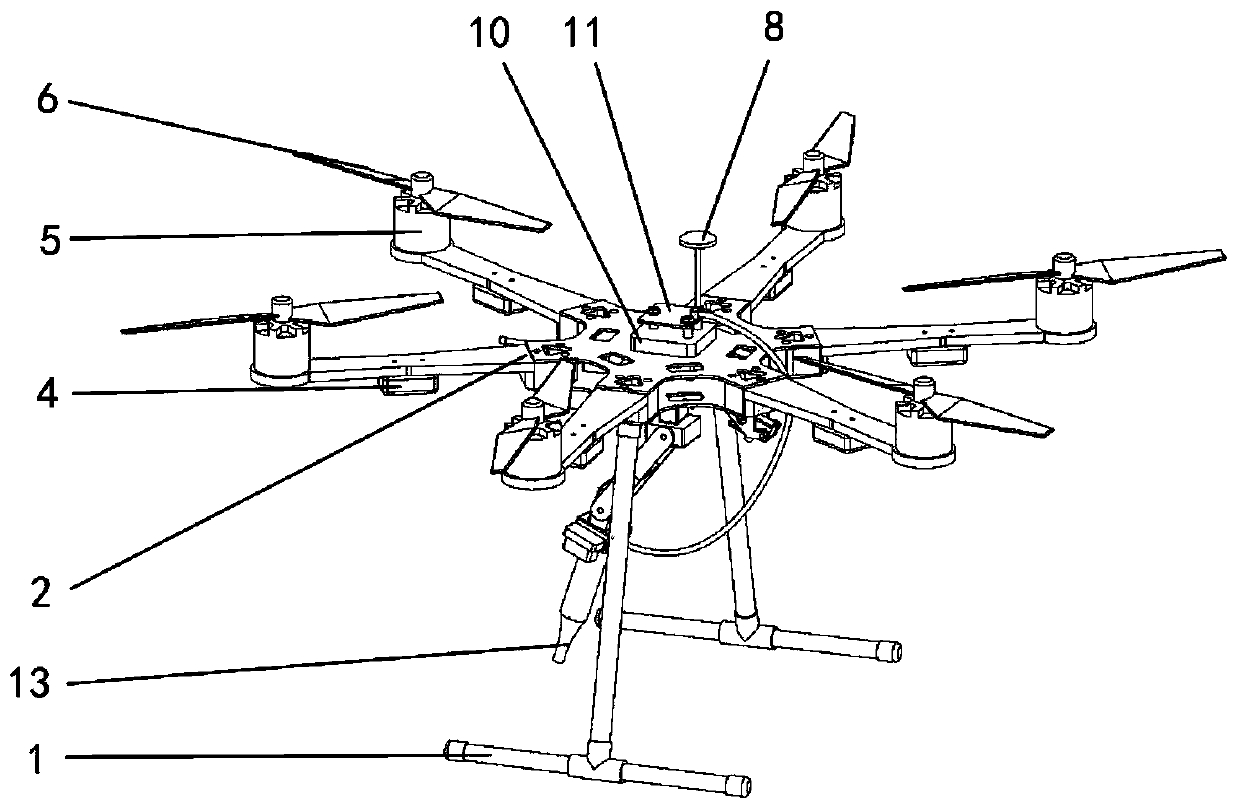

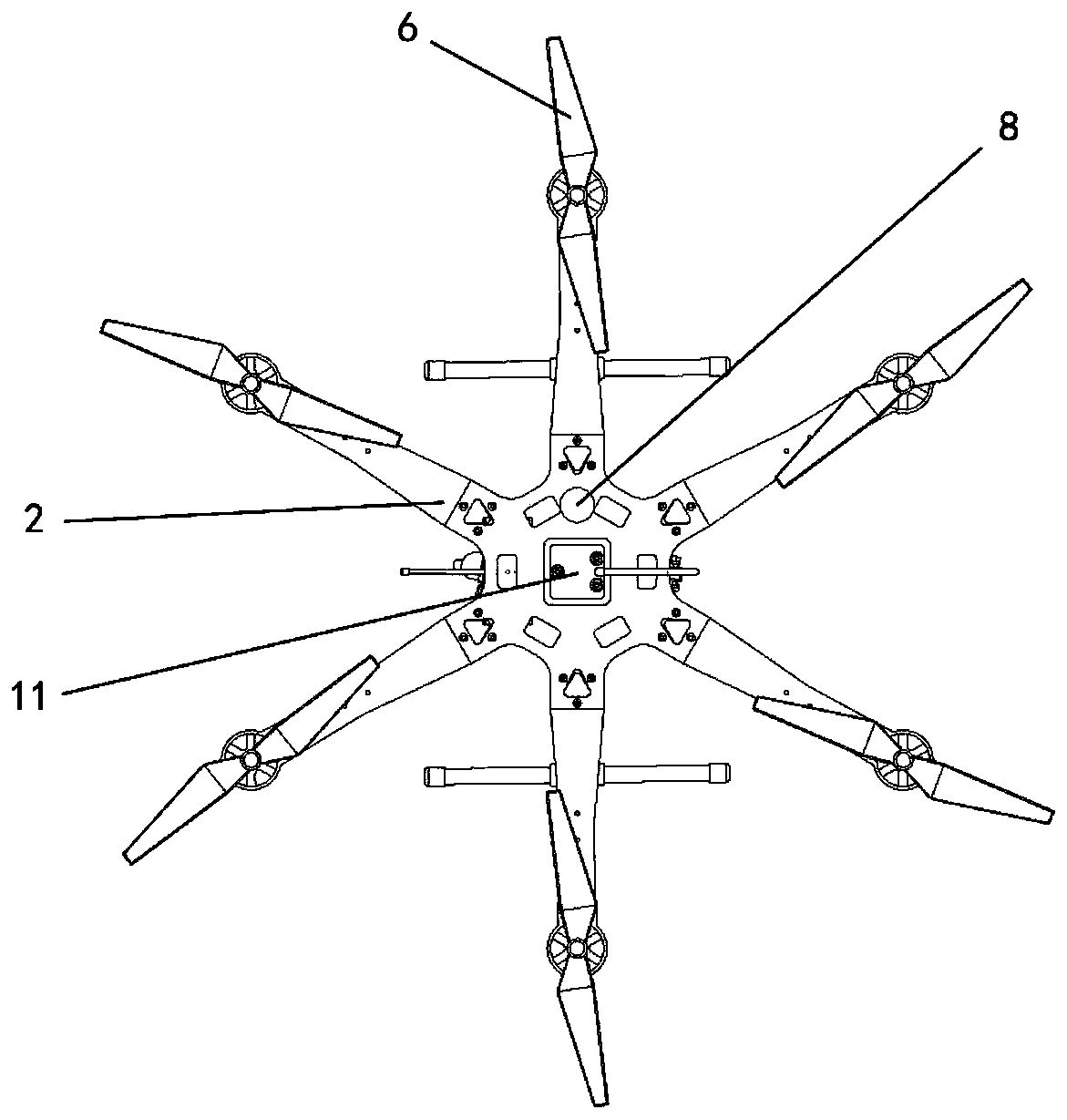

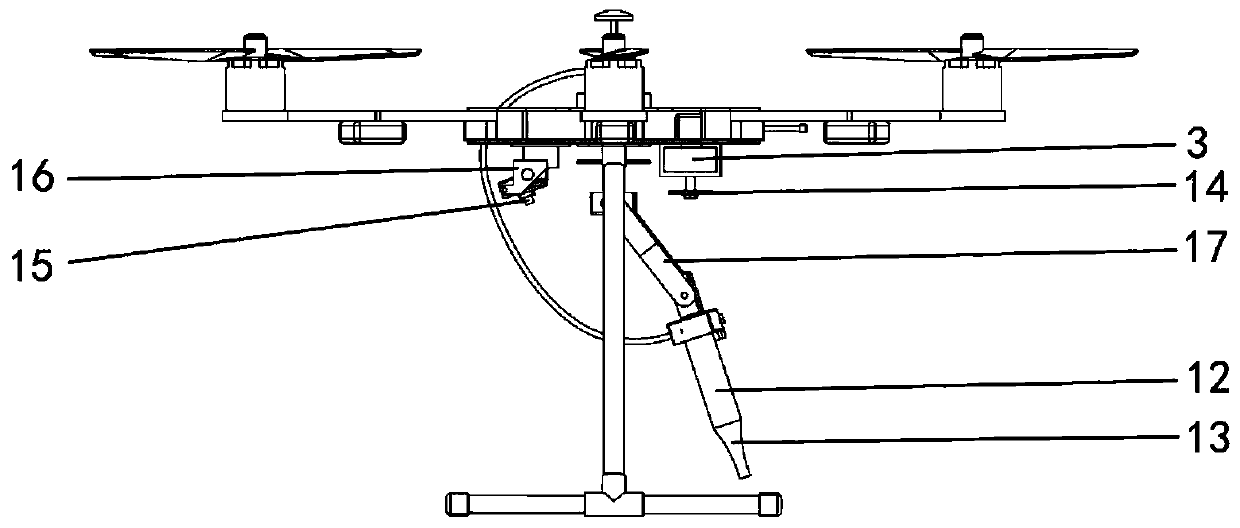

[0025] according to Figure 1 to Figure 6 As shown, the present invention provides a high-voltage cable deicing device based on ultrasonic deicing. Device 7, GPS8, remote control receiver 9, 220V power frequency mobile power supply 10, ultrasonic generator 11, ultrasonic transducer 12, deicing probe 13, deicing control unit 14, camera 15, camera pan / tilt 16, mechanical arm 17 , laser ranging module 18 and gyroscope 19;

[0026] The landing gear 1 is fixed on both sides below the frame 2, the battery 3 is fixed on one side of the bottom surface of the frame 2, the flight controller 7 is fixed at the center of the frame 2, and the GPS 8 is fixed on the frame 2 above, the remote control receiver 9 is fixed on one side of the frame 2, the electronic governor 4 is fixed on the cantilever of the frame 2, the motor 5 is connected with the electronic governor 4, the motor 5 and the propeller 6 The driving connection is fixed at the end of the cantilever of the frame 2, the 220V powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com