Defect solving means for metal hard photomask structure in 40/45 nanometer technology

A solution and metal technology, applied in the field of defect solutions for 40/45nm process metal hard mask structures, can solve the problems of metal disconnection, inability to remove residual charges, etc., to improve production quality and efficiency, solve The effect of metal power outage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

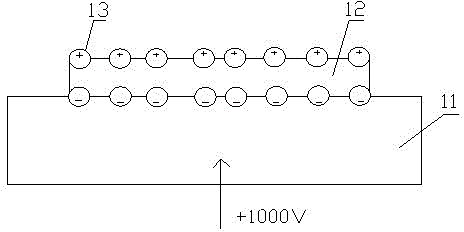

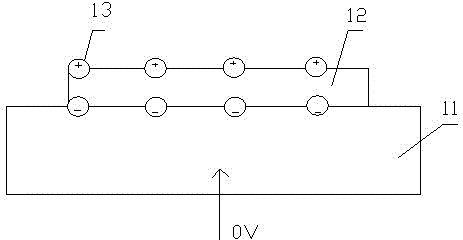

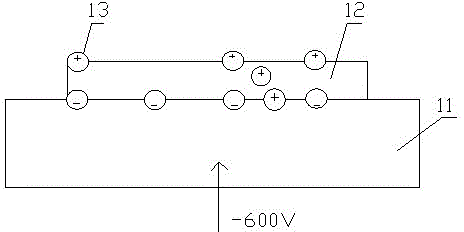

[0020] combine Figures 2a-2g As shown in , a solution to the defects of the 40 / 45 nanometer process metal hard mask structure, wherein the metal hard mask structure is to sequentially deposit the first dielectric layer 22 and the second dielectric layer on the metal sheet 21 23 and a composite structure 24; the composite structure 24 is divided into three layers, which are the first layer, the second layer, and the third layer from top to bottom; in one embodiment of the present invention, the metal sheet 21 is made of copper metal; The first dielectric layer 22 is a relatively high dielectric constant dielectric layer, the second dielectric layer 23 is an ultra-low dielectric constant dielectric layer, the composite structure 24 adopts the second layer as a TiN metal hard mask, the first lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com