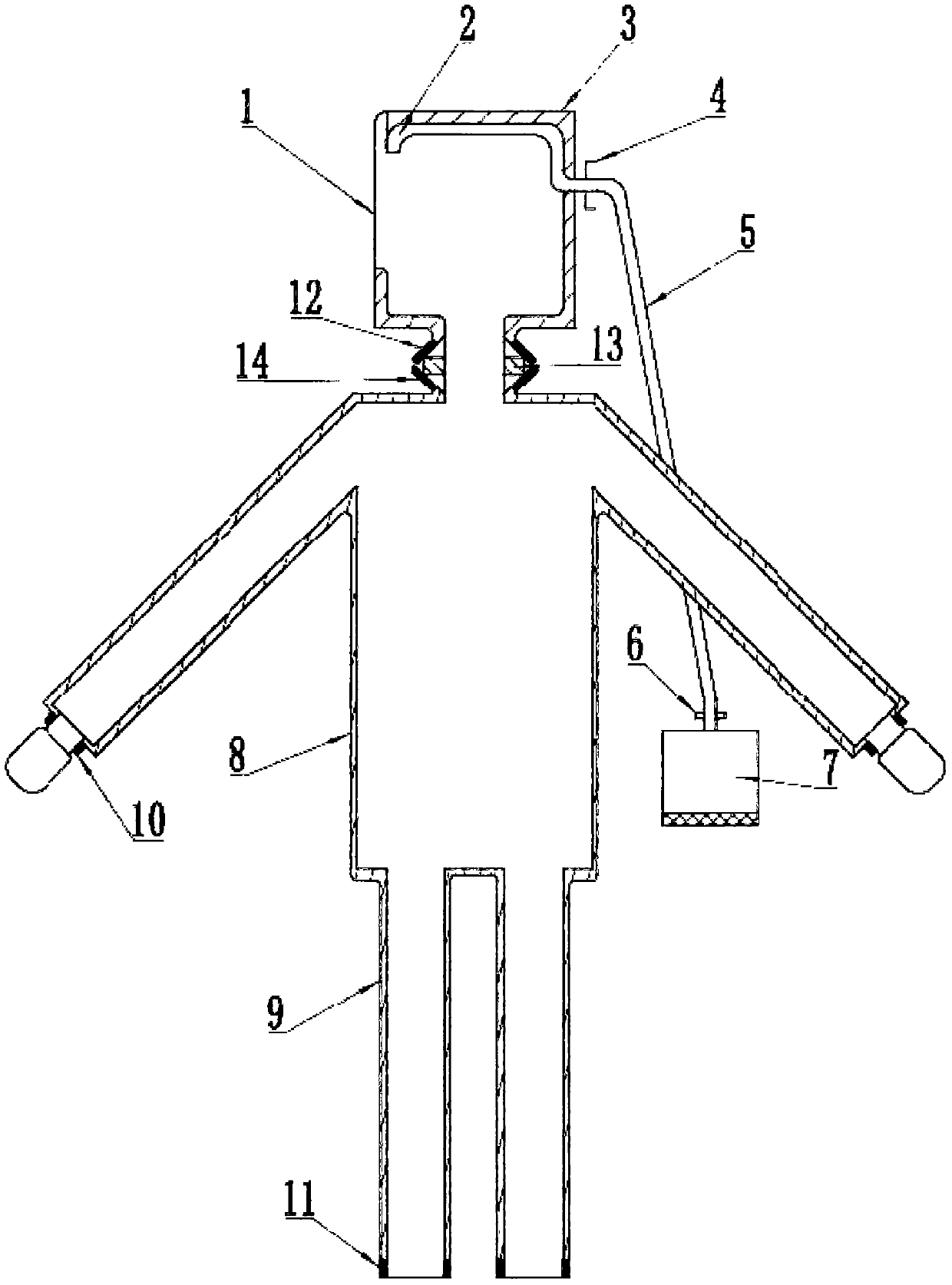

Protective clothing with excellent waterproof, breathable and barrier properties

A barrier performance, waterproof and breathable technology, applied in the field of medical protective clothing, can solve problems such as serious compression injuries, affecting visual effects, shortage of protective equipment, product quality, etc., to achieve protection protection, good barrier performance, and controllable leakage of air and water vapor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

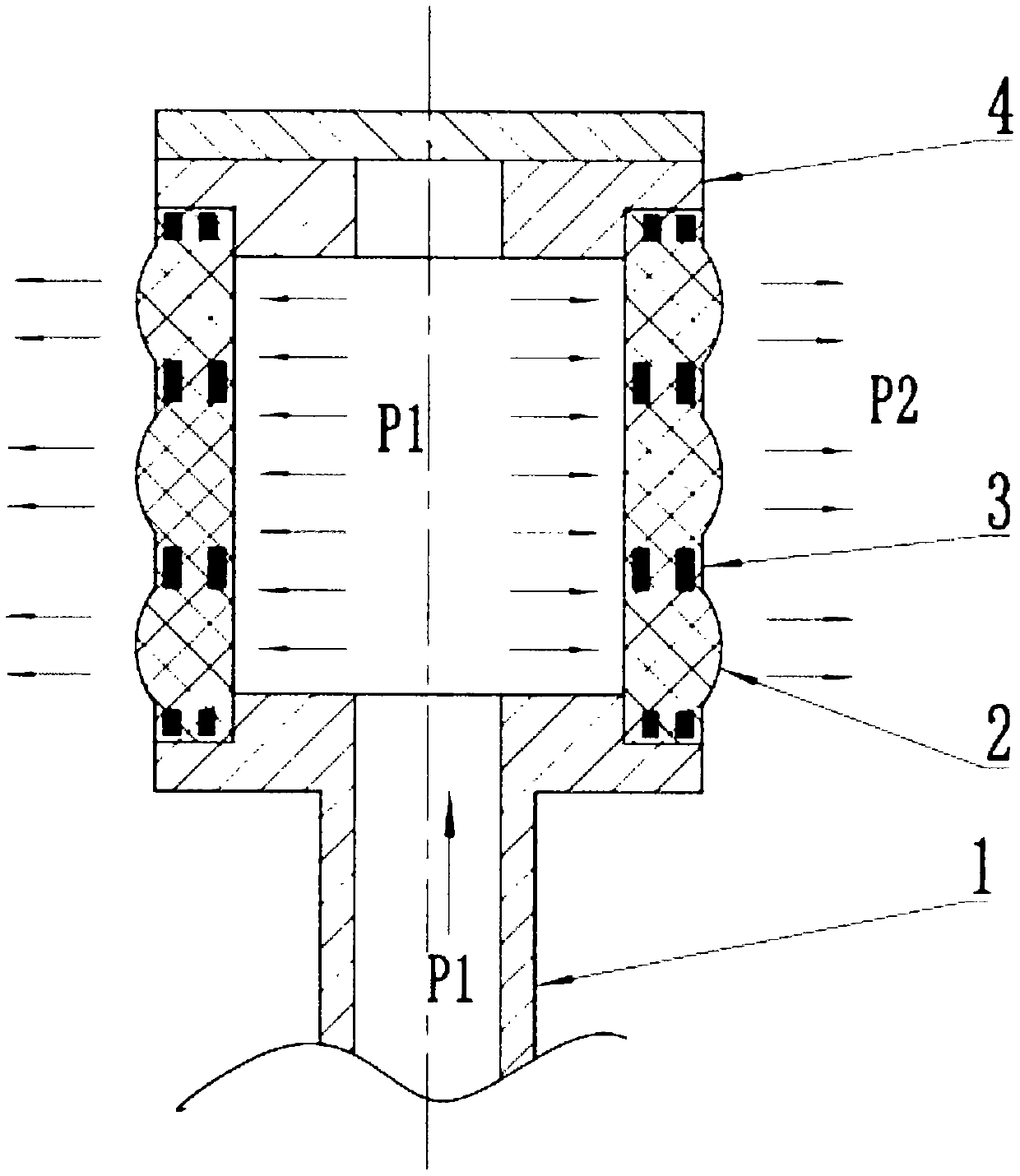

Method used

Image

Examples

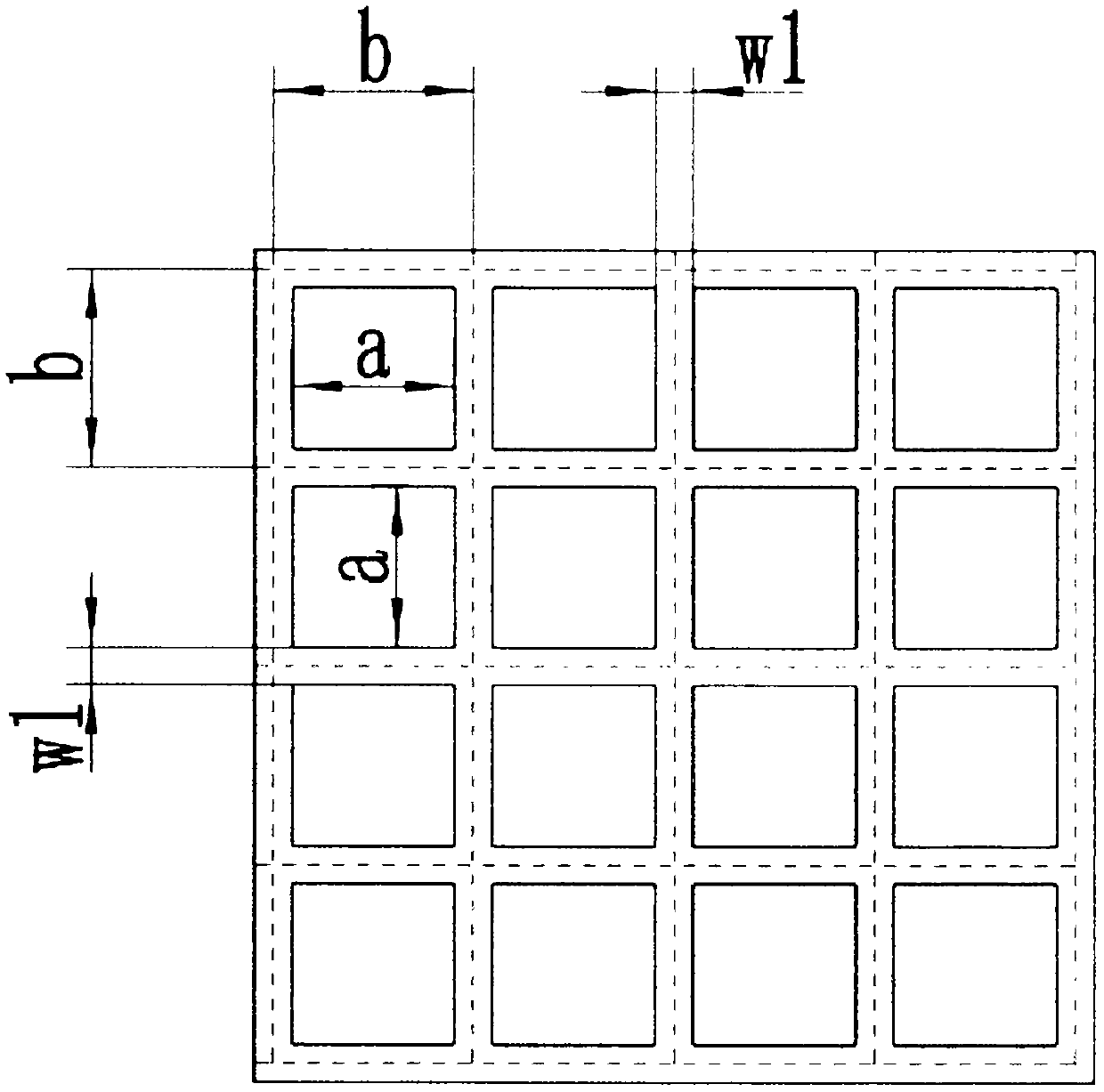

Embodiment Construction

[0022] Embodiment 1-7 adopts the microporous laminated composite material of different air permeability ratio, the intermediate layer of different air permeability structural parameters (microporous PE film with nanoscale aperture), different overall area of protective clothing, different internal positive pressure The value corresponds to the different intake / exhaust flow rates calculated. From the perspective of protective clothing of different sizes, the air permeability of the microporous PE film with nano-sized pores in the middle layer (reflecting the precise air resistance capacity of the material) is the key design and The control parameters require high accuracy of the parameters of the material in order to make practical and comfortable positive pressure protective clothing.

[0023] The specific physical and mechanical performance data of the material are related to the workability of the protective clothing, the resistance to positive pressure damage and shape sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com