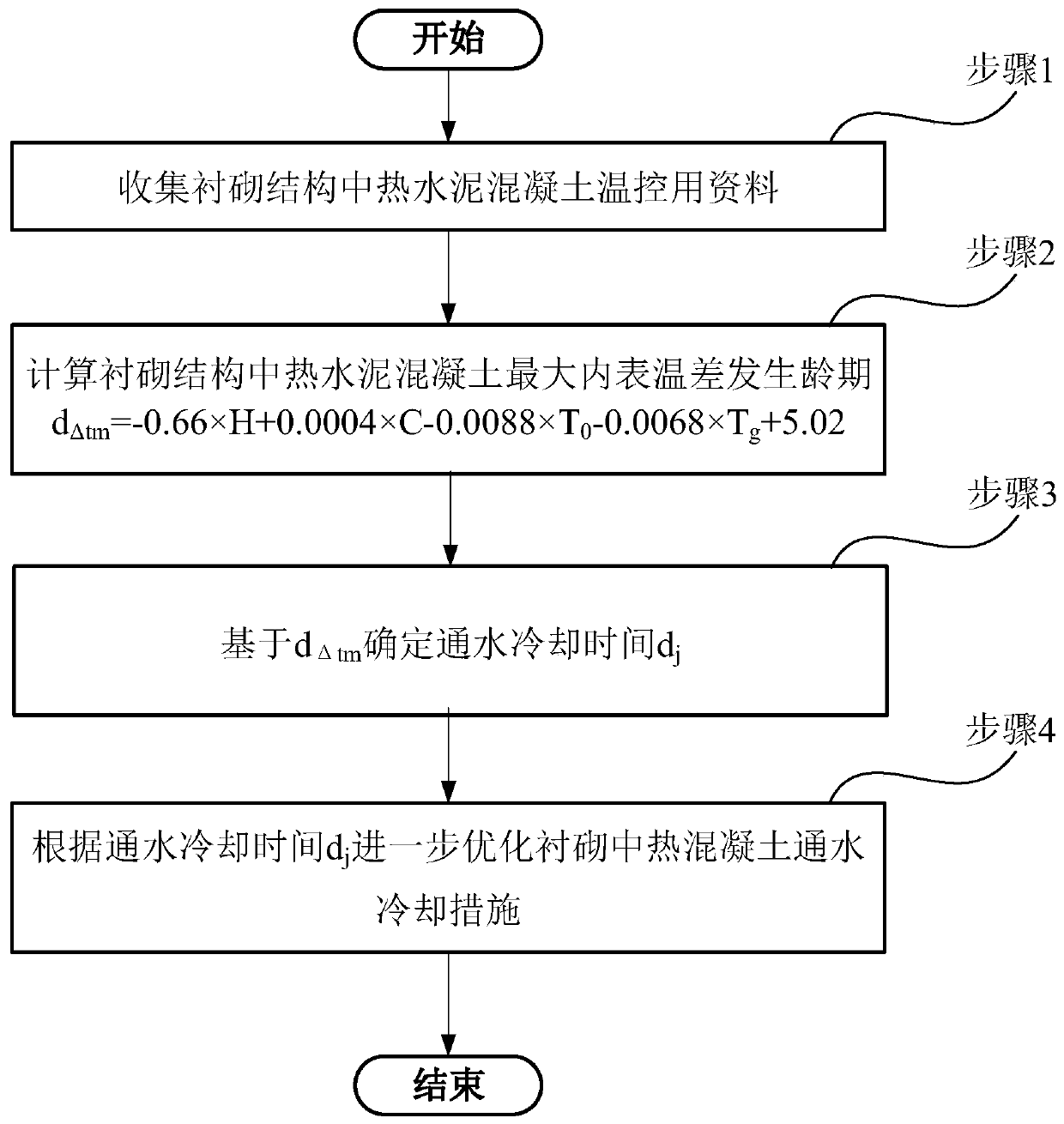

Medium-heat lining concrete water cooling method based on maximum inner surface temperature difference age

A water cooling and concrete technology, which is applied in the directions of hydropower generation, water conservancy projects, hydropower stations, etc., can solve the problems of no calculation method, reducing the maximum temperature and inner surface temperature difference of structural concrete, and no scientific method for determining the cooling time of water passing. , to achieve a scientifically strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1.0m thick (F2 type) lining

[0042] Taking the 1.0m thick (F2 type) lining as an example, the finite element method is used for simulation calculation. The calculation conditions are: start pouring on July 1, the pouring temperature is 27°C, no water cooling temperature control measures are taken, and the side wall adopts C 90 40 normal concrete, the top arch adopts C 25 For pumping concrete, only the side walls and the top arch are studied, and the base plate pouring is not considered. The formwork is removed after 3 days of pouring. The interval between side wall and top arch pouring is 31 days, and the length of the joint is 9m.

[0043] The maximum temperature, the maximum internal surface temperature difference and the occurrence time of the typical parts of the 1.0m thick (F2 type) lined concrete side wall are shown in Table 2 below, and the temperature duration curve is shown in Figure 5 .

[0044] Table 2 The maximum temperature and appearance time of repr...

Embodiment 2

[0058] The lining structure of the Xiluodu flood discharge tunnel is 0.8m and 1.5m thick with medium-heat cement concrete

[0059] In order to analyze the applicability of formula 1 for lining thickness and water cooling conditions, for Figure 4 For the section of the lining structure, keep the section size after lining unchanged and only change the thickness of the lining to 0.8m and 1.5m. First, use the finite element method to simulate and calculate, and then use formula 1 to calculate the maximum internal surface temperature difference occurrence age d Δtm Calculation.

[0060] Finite element simulation calculation, the calculation scheme in the case of water cooling is as follows: pouring starts on July 1 in summer, the bottom plate and side and roof arches are poured separately, and the pouring interval is 31 days; the pouring temperature is 18°C, the distance between water pipes is 1.0m, and the water Cool in water at 15°C for 15 days, remove the mold after 3 days, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com