Assembling and pouring integrated shear wall structure building system

A technology of shear walls and buildings, applied in buildings, building components, building structures, etc., can solve problems such as uncertain reliability of reinforced steel connections, reduce reliability of load-bearing structures, increase construction costs, etc., and eliminate design and construction Hidden dangers, reasonable structural optimization, and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing.

[0047] The assembly and pouring integrated shear wall structure construction system of the present invention includes floor slabs, a shear wall skeleton structure and wall formwork arranged on both sides of the shear wall skeleton structure, and concrete is poured in the shear wall skeleton structure;

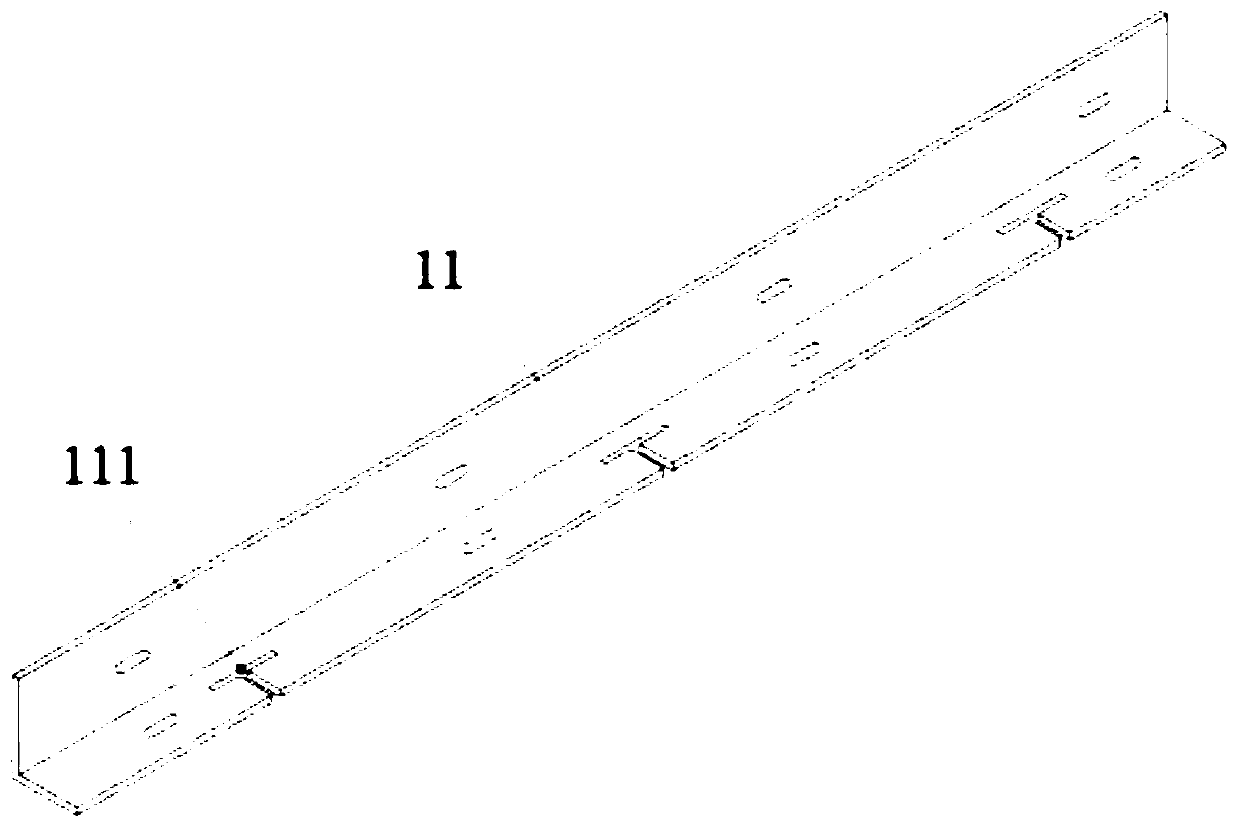

[0048] The shear wall skeleton structure includes several unit planar skeletons 1 and unit three-dimensional skeletons 2;

[0049] Such as figure 2 As shown, the unit planar skeleton includes two horizontal members 11 up and down and several vertical members 12 fixedly connected vertically with the horizontal members. The connection points between the vertical members and the horizontal members at both ends are located For vertical components, according to design requirements, several vertical components can also be added in the middle, and opening beams 13 can also be add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com