Lubricating oil supply system with independent direct-current power supply systems and without emergency oil pump

A technology of DC power supply system and oil supply system, which is applied in the direction of engine lubrication, lubrication pump, control system, etc. It can solve the problems of endangering the shafting safety of generator sets, interruption of lubricating oil supply, and large heat generation, so as to improve economy and The effect of social benefits, fast speed-up, and short time-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

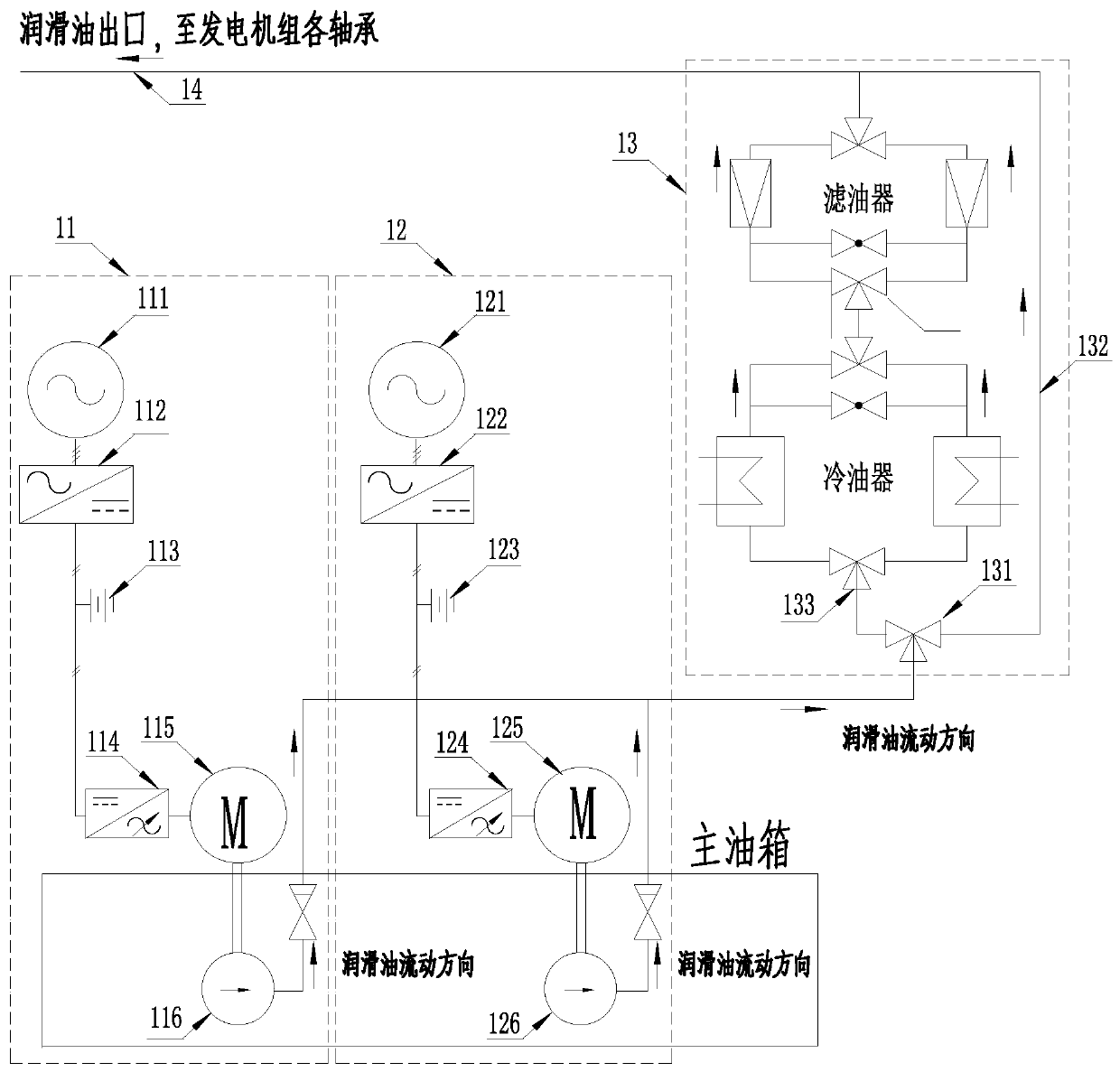

[0028] The invention protects a lubricating oil supply system with an independent DC power supply system and no emergency oil pump. like figure 1As shown, it includes a first oil supply module 11, a second oil supply module 12, a lubricating oil treatment module 13 and a lubricating oil outlet 14, wherein, the above-mentioned first oil supply module 11 includes The first AC power supply 111 , the first rectifier 112 , the first DC power supply system 113 , the first inverter 114 , the first electric motor 115 and the first main oil pump 116 are sequentially connected. The above-mentioned second oil supply module 12 includes a second AC power supply 121, a second rectifier 122, a second DC power supply system 123, a second inverter 124, a second motor 125 and a second main Oil pump 126. Wherein, the first main oil pump 116 driven by the above-mentioned first electric motor 115 and the second main oil pump 126 driven by the above-mentioned second electric motor 125 are both us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com