Offshore wind power suction pile foundation

An offshore wind power and suction pile technology, applied in wind power generation, infrastructure engineering, installation/support of wind turbine configuration, etc., can solve problems such as large bending moment, suction pile soil failure, etc. Overturning moment, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

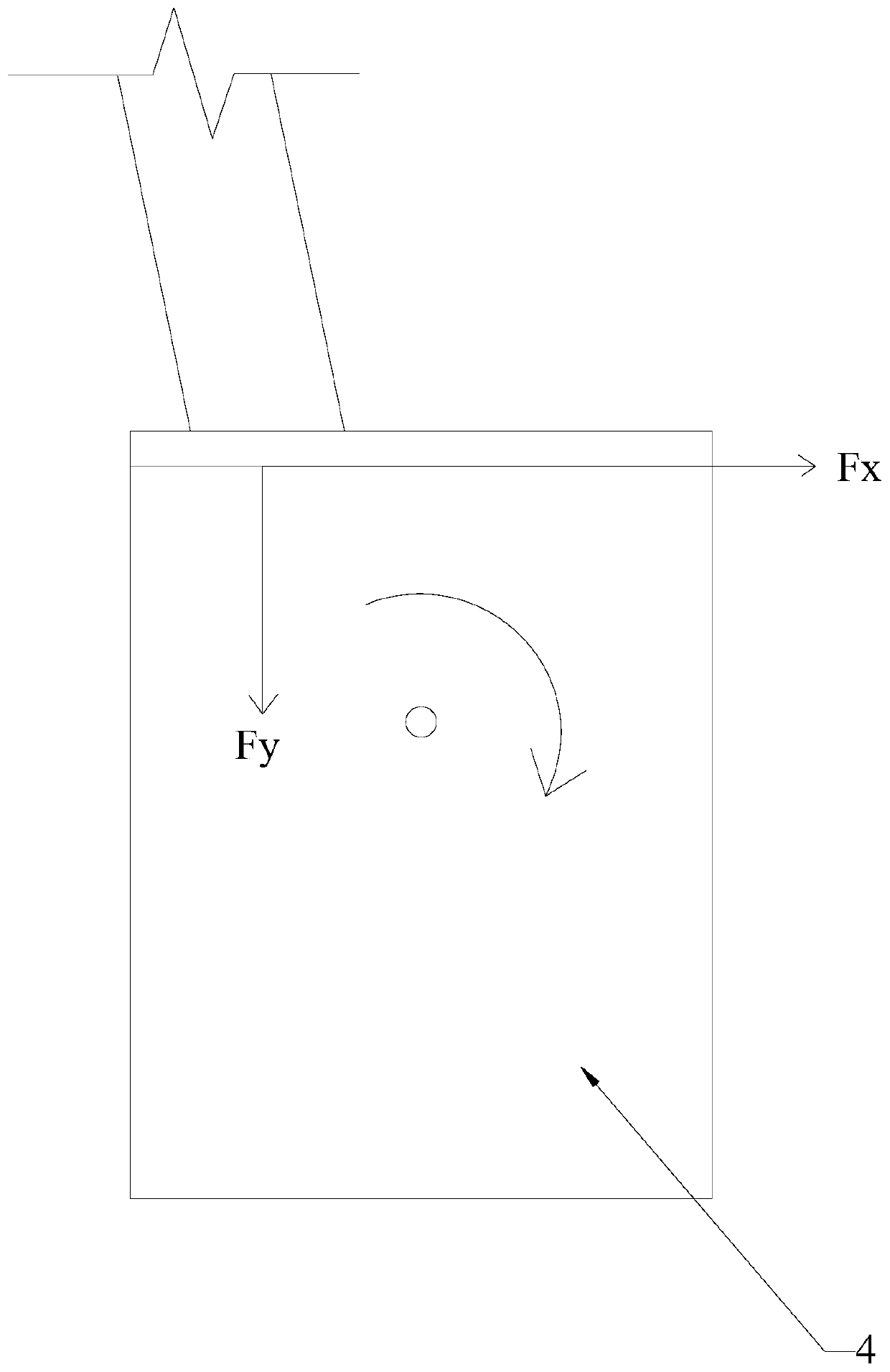

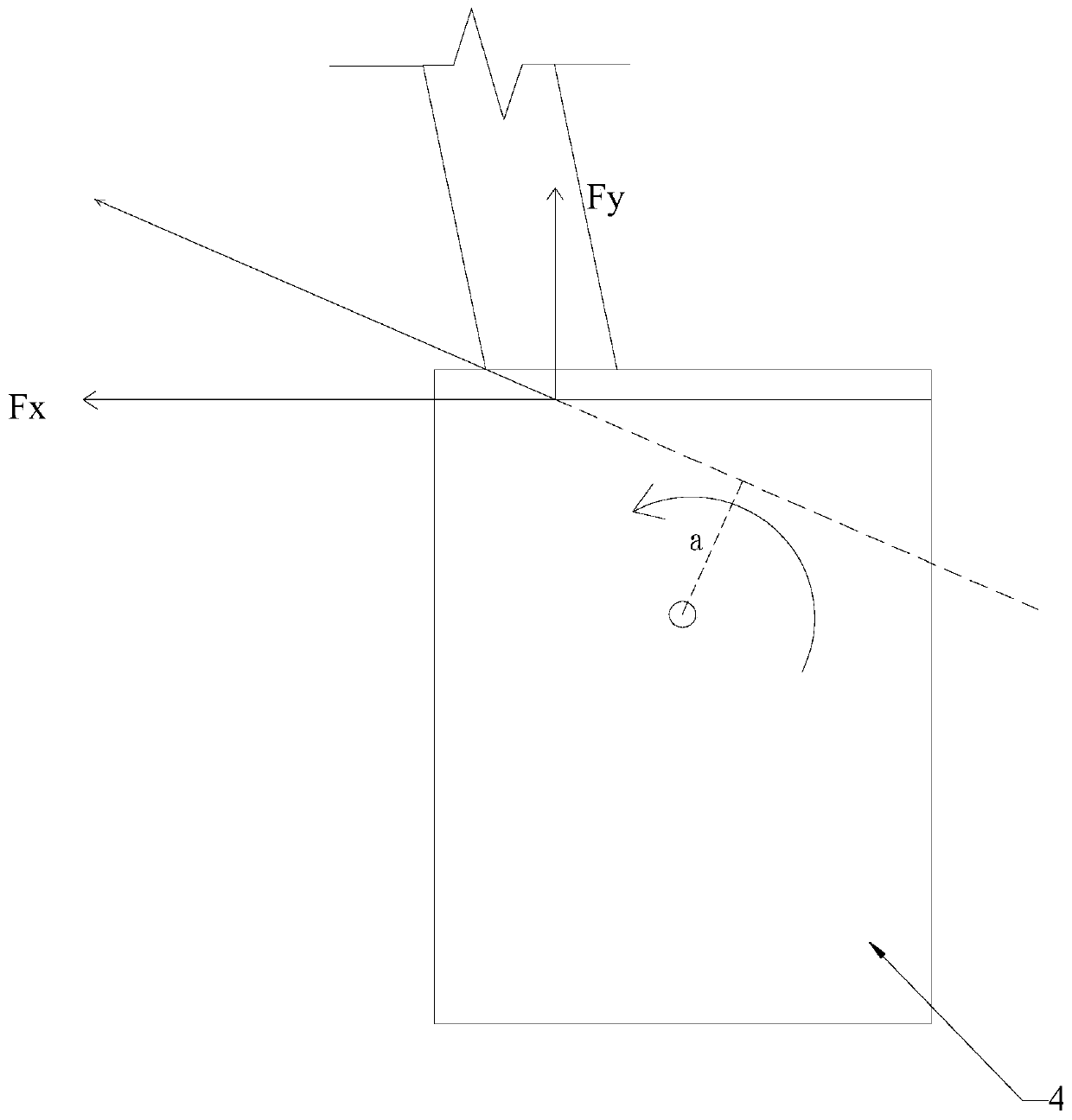

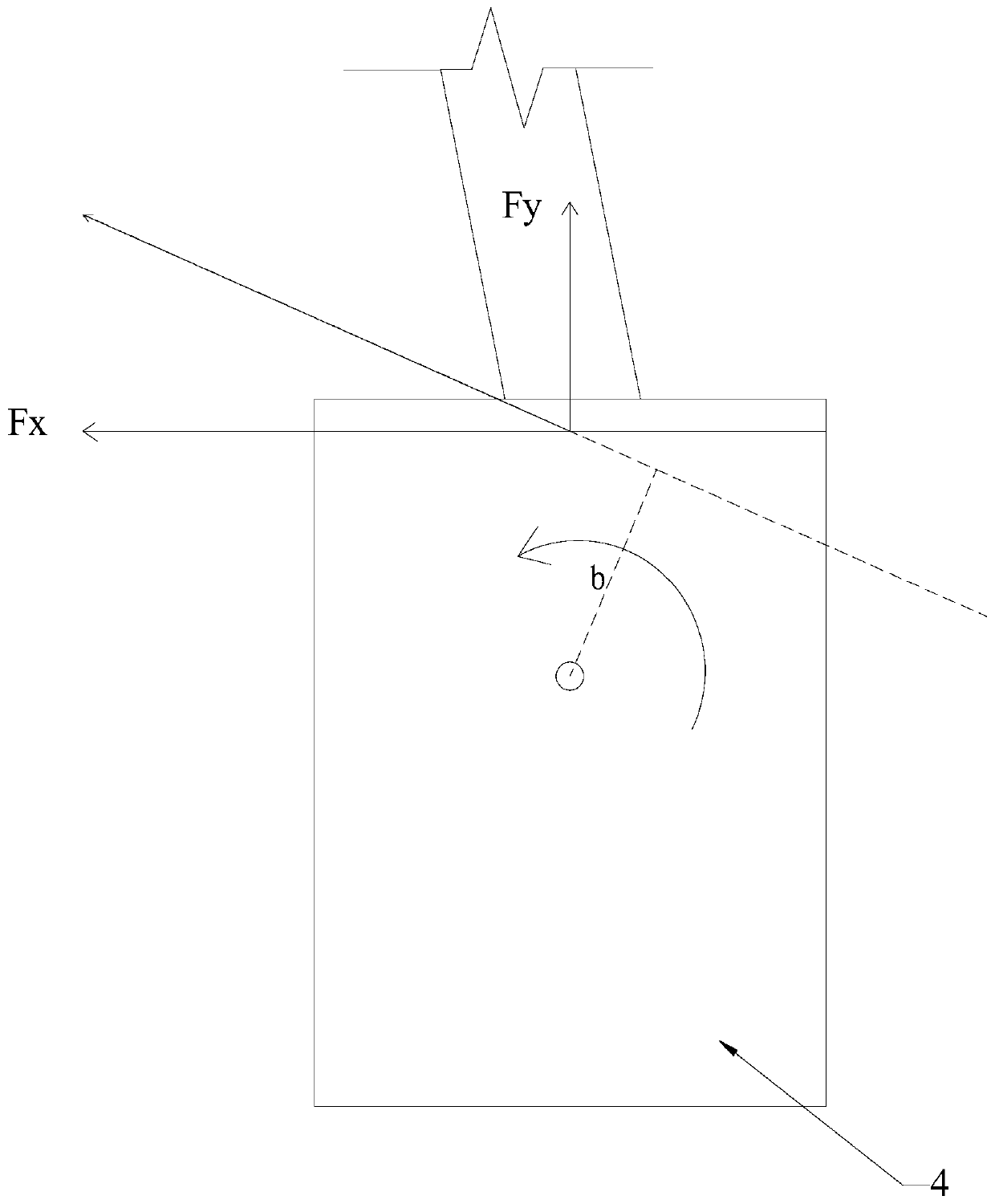

[0042] An offshore wind power suction pile foundation, comprising a wind turbine tower 1, a tower frame 2, a suction pile connection section 3 and a suction pile body 4; the wind turbine tower 1 is vertically connected to the center of the upper part of the tower frame 2, the The lower end of the tower frame 2 is provided with more than three connecting columns 5, the number of the suction pile body 4 is the same as the number of connecting columns 5, and the lower end of each connecting column 5 is respectively connected to the The upper part of the suction pile body 4, the shortest distance between the lower end of each connecting column 5 and the axis of the fan tower 1 is the same; the shape of the suction pile body 4 is a hollow cylinder with an open lower part and a closed upper part, and the connecting column The vertical extension line of the lower end of 5 is located inside the axis of the correspondingly connected suction pile body 4. The axes in turn lie in the same...

Embodiment 2

[0044] An offshore wind power suction pile foundation is characterized in that it includes a wind turbine tower 1, a tower 2, a suction pile connection section 3 and a suction pile body 4; the wind turbine tower 1 is vertically connected to the top of the tower 2 At the center, the lower end of the tower 2 is provided with more than three connecting columns 5, the number of the suction pile body 4 is the same as that of the connecting columns 5, and the lower end of each connecting column 5 passes through the connecting section of the suction pile respectively. 3 are respectively connected to the upper part of the suction pile body 4, and the shortest distance between the lower end of each connecting column 5 and the axis of the wind tower 1 is the same; the shape of the suction pile body 4 is a hollow cylinder with an open lower part and a closed upper part, The vertical extension line of the lower end of the connecting column 5 is located inside the axis of the correspondingl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com