Microelectrode system and method for testing oxygen mass transfer coefficient of proton exchange membrane

A proton exchange membrane and mass transfer coefficient technology, applied in measuring devices, material analysis by electromagnetic means, instruments, etc., can solve the problem of consuming large catalyst and membrane materials, time-consuming and labor-intensive assembly of batteries, and difficulty in obtaining the influence of binders, etc. problem, achieve the effect of saving battery materials and simplifying the testing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

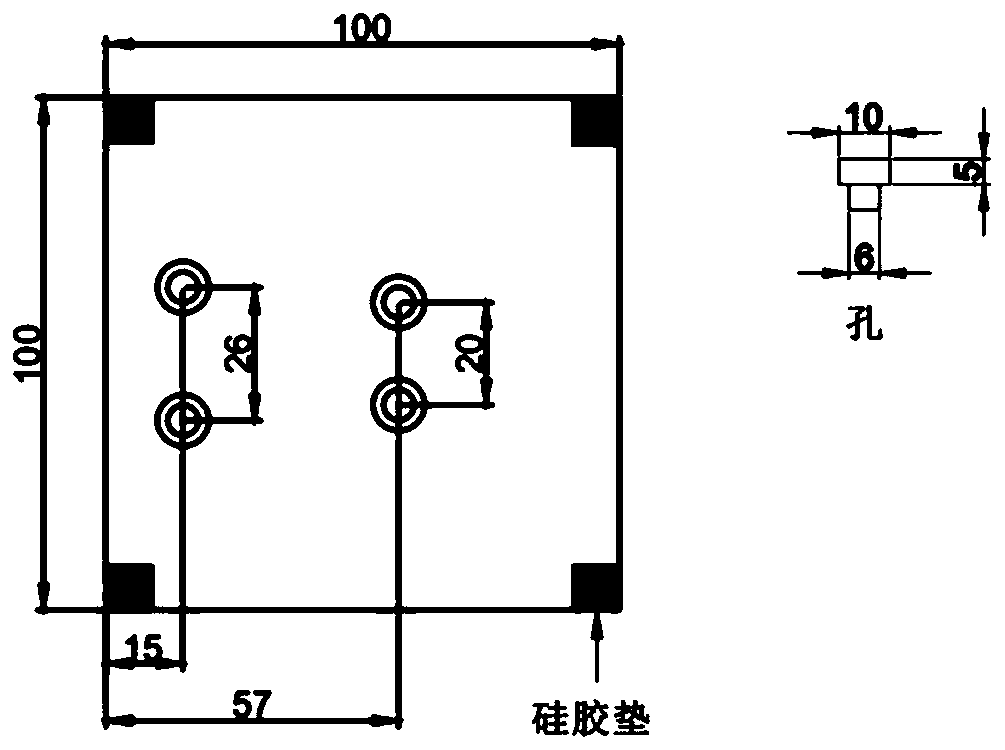

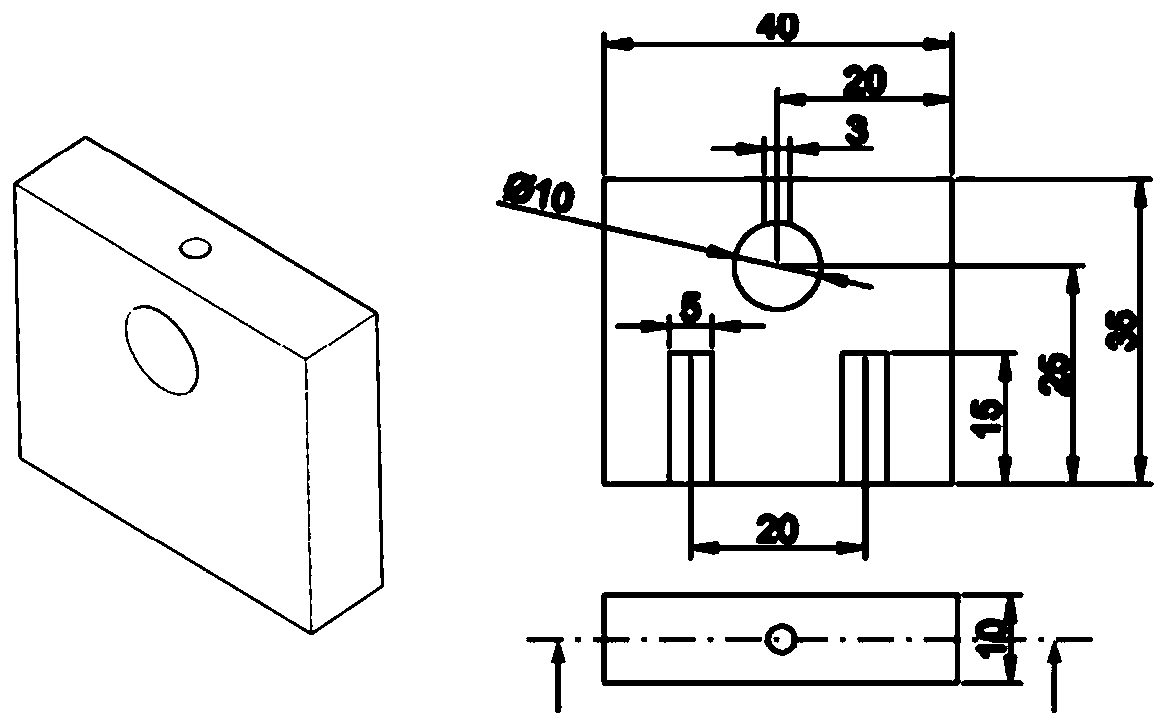

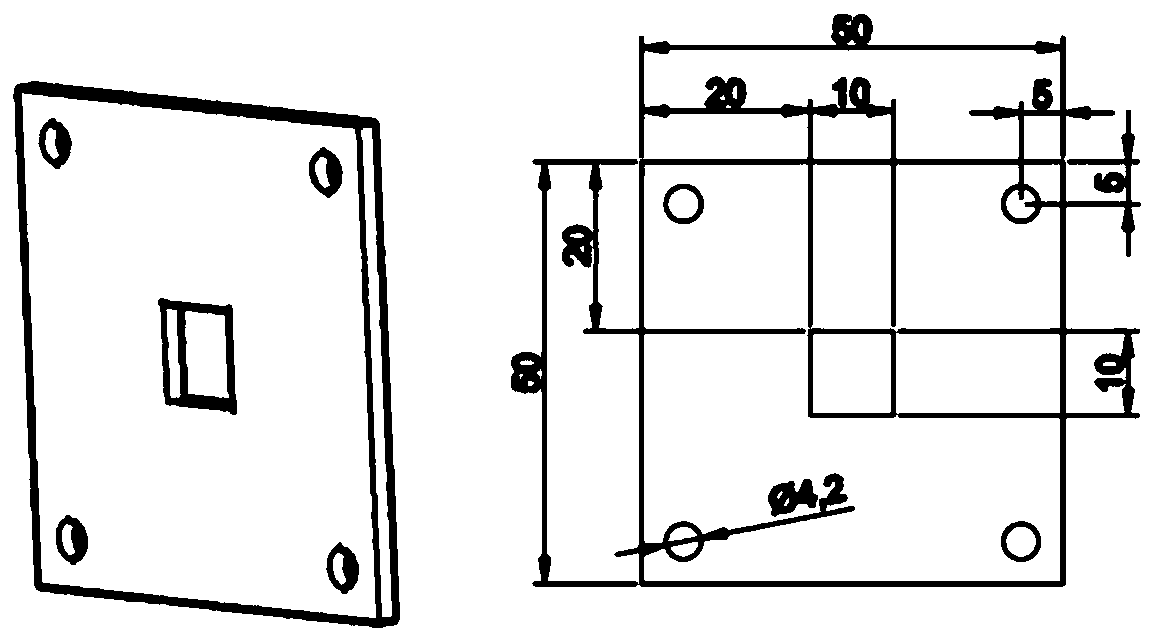

[0032] The base is made of aluminum alloy, with a length of 100mm, a width of 100mm, and a thickness of 10mm. There are inverted T-shaped holes on it. The position and diameter of the holes are as follows: figure 1 As shown, in addition, a 10mm long, 10mm wide, and 5mm thick silicone pad is attached to the four corners of the bottom surface of the bottom plate to lift the bottom plate to prevent the device from being overheated during operation and damaging the environmental cavity. The support plate is made of aluminum alloy, 40mm long, 10mm wide, and 35mm high. There are two M5 threaded holes on the bottom, one M3 threaded hole on the top, and a circular through hole with a diameter of 10mm on the front. The specific hole positions are as follows: figure 2 shown. The splint 1 is made of aluminum alloy, with a length of 50 mm, a width of 2 mm, and a height of 50 mm. Its four corners have circular through holes with a diameter of 4.2 mm, and the middle has a square through ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com