Metal pipe fitting polishing machine

A technology for metal pipe fittings and polishing machines, which is used in surface polishing machine tools, metal processing equipment, grinding/polishing equipment, etc. It can solve the problems of clamping and polishing metal pipe fittings of different sizes and specifications, and achieve the effect of preventing wear scars. , reduce environmental pollution and ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

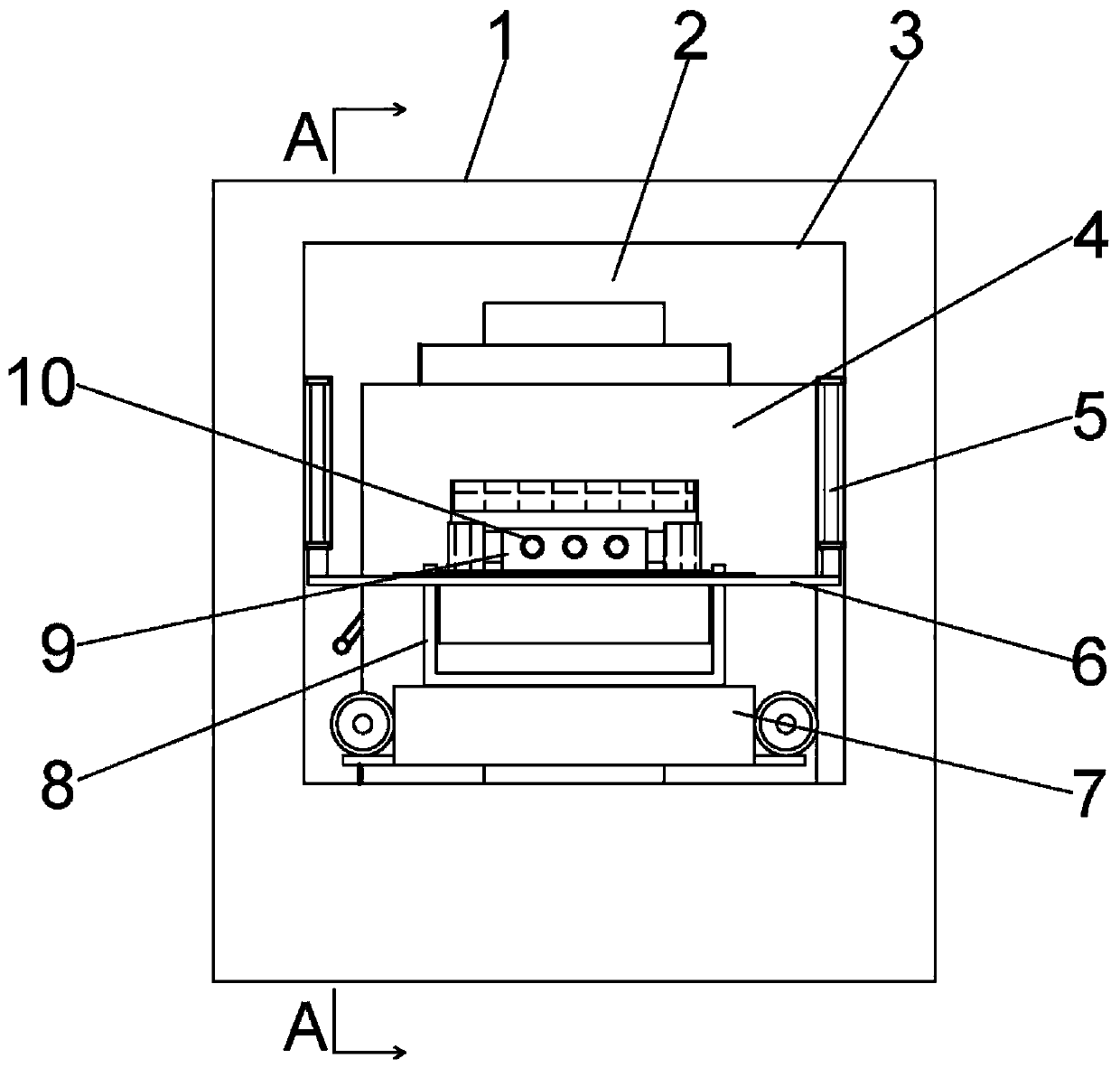

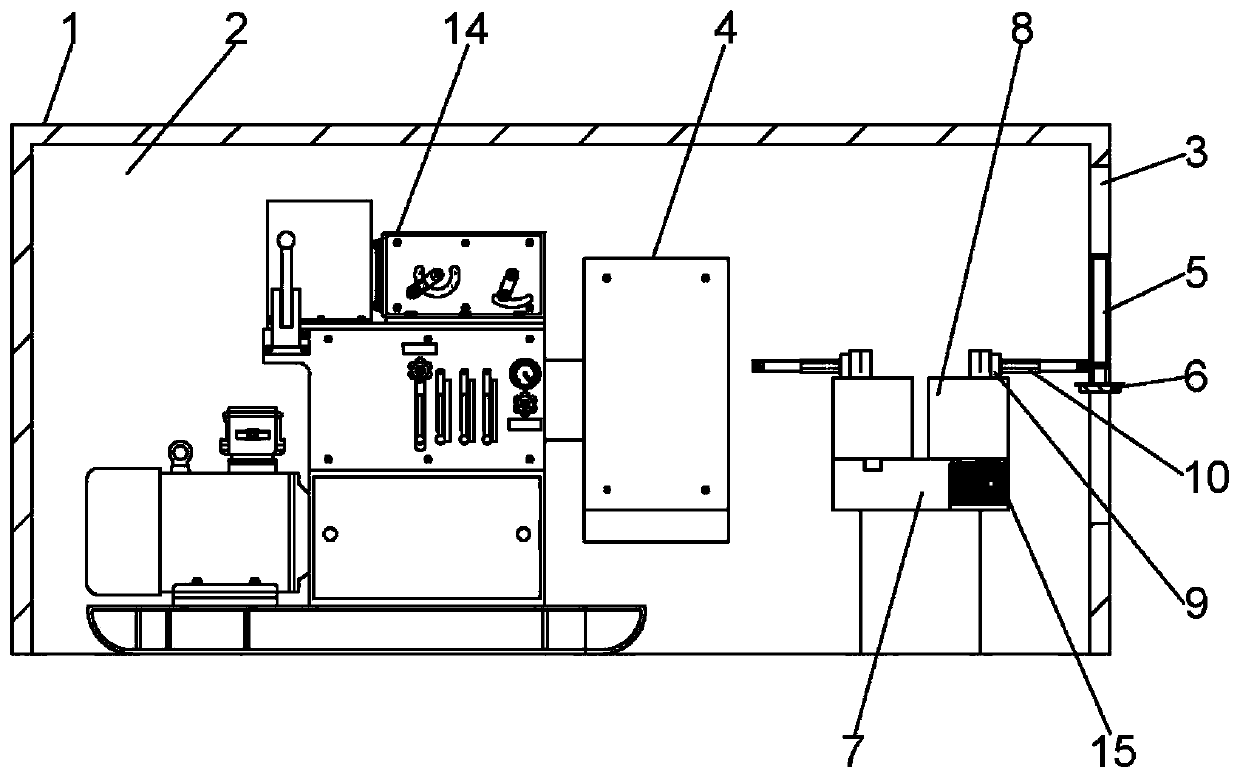

[0035] Such as figure 1 and image 3 In the described embodiment, a metal pipe polishing machine includes a box body 1, a box body cavity 2 is provided in the box body 1, a turntable 7 and a machine base 14 are fixed on the bottom surface of the box body cavity 2, and the turntable 7 There are several placement frames 8 evenly distributed on the edge of the upper end surface, the placement frames 8 and the turntable 7 are slidingly connected, the placement frame 8 is fixed with a fixed plate 9, and several installation components 10 are evenly distributed on the side of the fixed plate 9.

[0036] Such as figure 1 and Figure 12 As shown, the mounting assembly 10 includes a rotating base 46, which is rotationally connected to the fixed plate 9, and a rotating rod 47 is rotationally connected to the rotating base 46, and a mounting sleeve 48 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com