Stable small molecular group water preparation device and method

A technology of small molecular mass water and preparation device, which is applied in the field of small molecular mass water preparation device, can solve problems such as the inability of small molecular water to be stable, and achieve the effects of reducing eyeball congestion and speeding up the cutting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

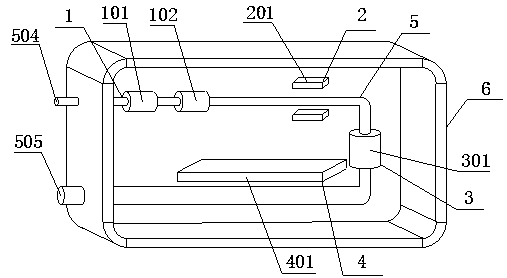

[0038] Such as figure 1 As shown, a stable small molecule water preparation device includes a pre-filter unit 1, a strong magnetic cutting unit 2, a post-ultrafiltration unit 3 and a stabilization unit 4 arranged sequentially along the pipeline 5, and the pre-filter Unit 1 includes a coarse filter 101 and a fine filter 102, and the pipeline 5 passes through the coarse filter 101 and the fine filter 102 in turn. The strong magnetic cutting unit 2 includes at least one group of strong magnets 201, and the same group of strong magnets 201 are symmetrically arranged on the pipeline. 5, the post ultrafiltration unit 3 is a membrane filter 301, and the stabilizing unit 4 includes an ultrasonic power meter 401, which emits ultrasonic waves to the pipeline 5.

[0039] In this embodiment, the coarse filter 101 adopts an activated carbon filter, which can filter out larger impurities, and the fine filter 102 adopts a filter of a 5 μm hollow fiber material, which can filter out micron-si...

Embodiment 2

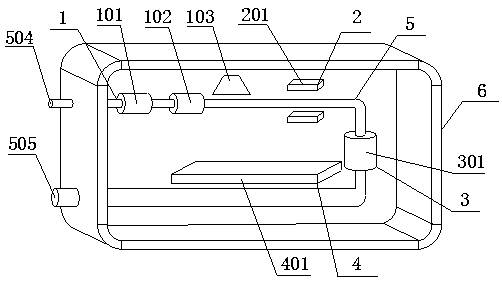

[0044] Such as figure 2 In this embodiment, on the basis of Embodiment 1, the filter unit 1 in the device further includes a sterilizing device 103 , and the sterilizing device 103 is located at the rear end of the fine filter 102 .

[0045] In this embodiment, the raw water is further treated by the sterilizing device 103 to be free of impurities and bacteria. The sterilizing device 103 is an ultraviolet sterilizer, specifically an ultraviolet disinfection lamp.

Embodiment 3

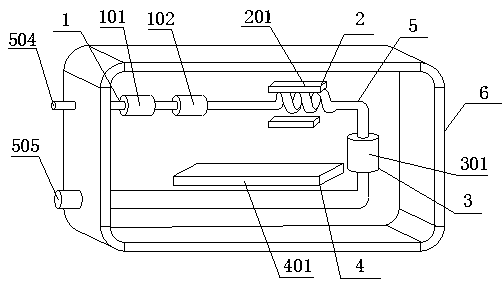

[0047] Such as image 3 In this embodiment, on the basis of Embodiment 1, the part of the pipe 5 in the device located in the strong magnetic cutting unit 2 is in a spiral shape. The length of the pipeline 5 is greatly increased, but the length of the magnetic field is not increased, and the water continuously rotates to speed up the cutting speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com