Method for preparing garden rockery by utilizing construction waste regeneration

A technology of construction waste and rockery, applied in construction waste recycling, recycling technology, manufacturing tools, etc., can solve the problems of large amount of construction waste and impact on the environment, so as to avoid adverse effects, beautify and purify the environment, and have strong simulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

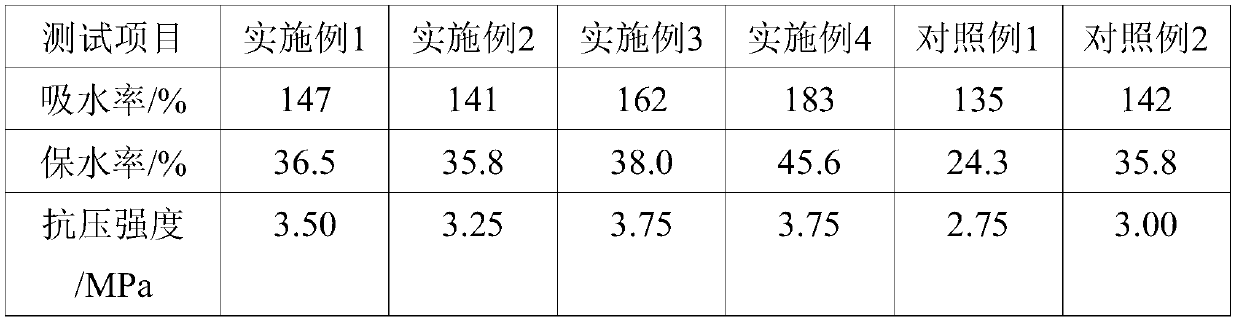

Examples

Embodiment 1

[0028] Processing of rockery:

[0029] (1) Mold making: the mold includes an outer mold and an inner mold, and the mold is made according to the established rockery structure;

[0030] (2) Construction waste crushing: the construction waste is made into a powder with a particle size of less than 2mm after coarse crushing and fine crushing;

[0031] (3) Mixing: add the above-mentioned 137kg waste concrete construction waste, 24kg polycaprolactone, 38kg Portland cement, 12kg nano-calcium carbonate, 2kg naphthalene-based water reducer, and 3kg aluminate coupling agent to the mixture in proportion machine, and add water to adjust the solid content of the resulting mixture to 70%, mix evenly, and obtain the rockery processing material;

[0032] (4) Pouring: import the above-mentioned materials into the mold, insert the vibrating rod into the mold, vibrate and tamp the material, and replenish the material until the material is tamped and flush with the opening of the mold;

[0033...

Embodiment 2

[0037] The difference between embodiment 2 and embodiment 1 is the change of raw material consumption.

[0038] Processing of rockery:

[0039] (1) Mold making: the mold includes an outer mold and an inner mold, and the mold is made according to the established rockery structure;

[0040] (2) Construction waste crushing: the construction waste is made into a powder with a particle size of less than 2mm after coarse crushing and fine crushing;

[0041] (3) Mixing: add the above-mentioned 132kg waste concrete construction waste, 21kg polycaprolactone, 36kg Portland cement, 10kg nano-calcium carbonate, 2kg naphthalene-based water reducer, and 2kg aluminate coupling agent to the mixture in proportion machine, and add water to adjust the solid content of the resulting mixture to 70%, mix evenly, and obtain the rockery processing material;

[0042] (4) Pouring: import the above-mentioned materials into the mold, insert the vibrating rod into the mold, vibrate and tamp the material...

Embodiment 3

[0047] With embodiment 1 as contrast, the embodiment 3 that replaces nano-calcium carbonate with equal amount of nanometer talcum powder is set, and all the other processing operations are exactly the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com