Water jet cleaning system and cleaning method of converter vaporization cooling flue

A technology for vaporizing cooling flue and cleaning system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

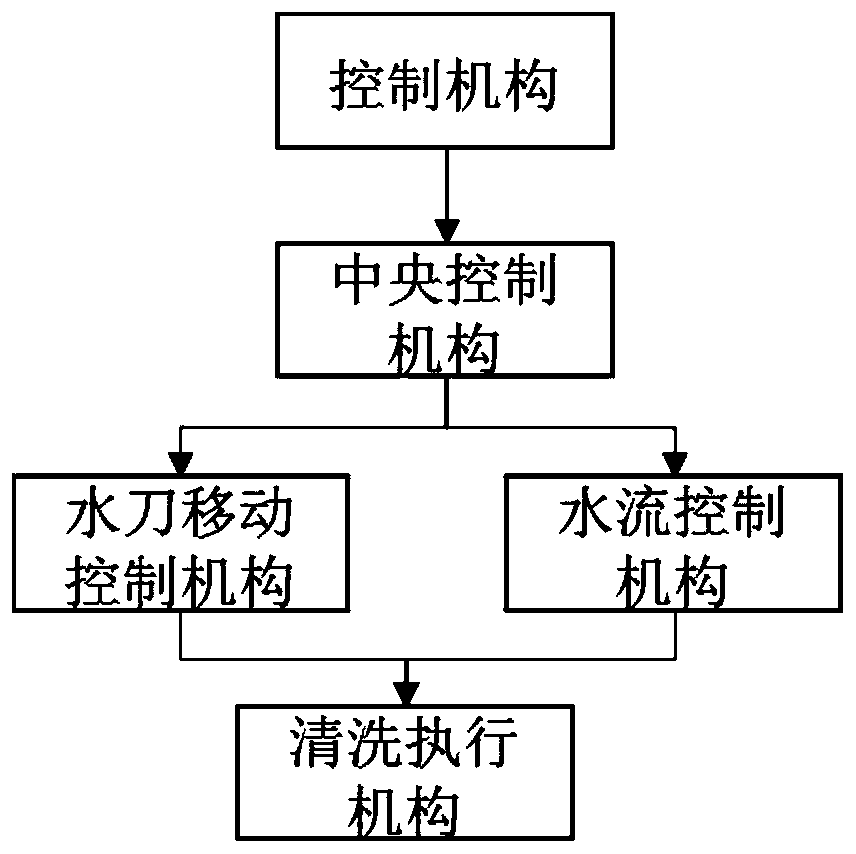

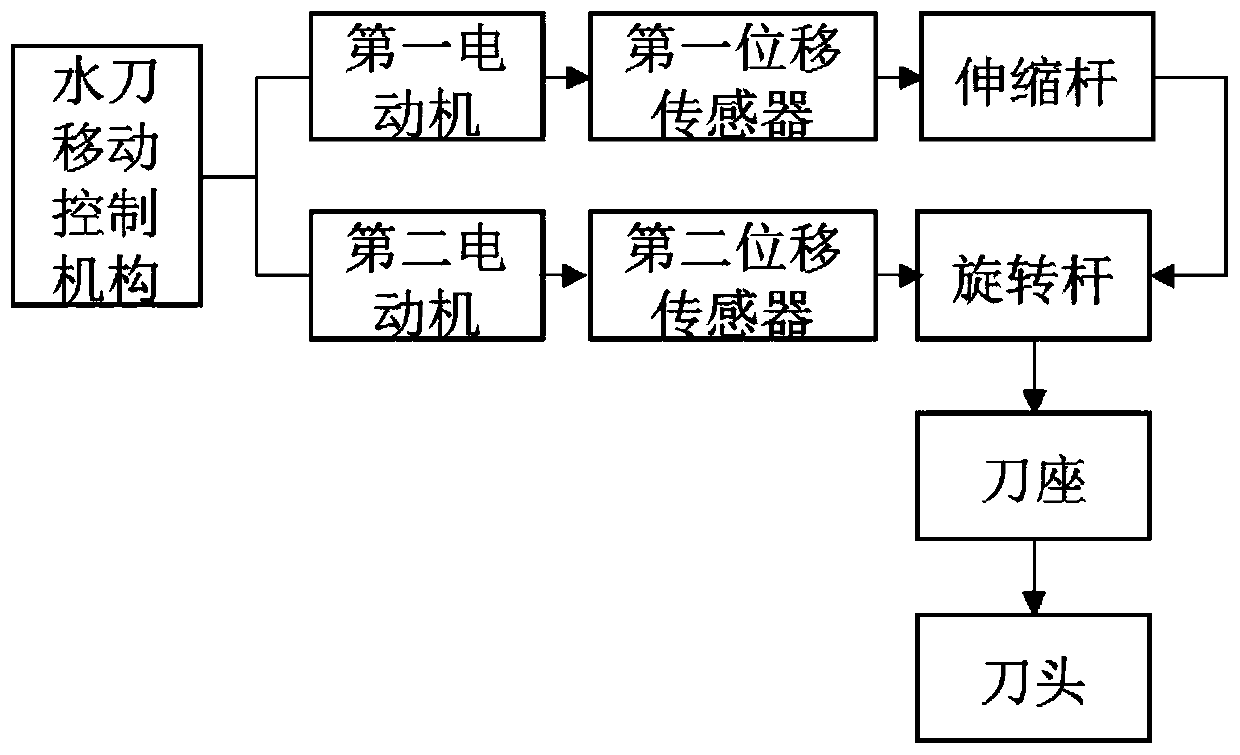

[0038] see Figure 1 to Figure 4 As shown, the water jet cleaning system of a converter vaporization cooling flue (hereinafter referred to as the flue) provided by the present invention includes a control mechanism and a cleaning executive mechanism; the control mechanism includes a central control mechanism, a water jet movement control mechanism and a water flow Control mechanism; the central control mechanism is respectively connected with the water knife movement control mechanism and the water flow control mechanism, and the water knife movement control mechanism and the water flow control mechanism are both connected with the cleaning executive mechanism; the water knife movement control mechanism The water flow control mechanism is used for controlling the telescopic movement and the rotation movement of the cleaning actuator, and the water flow control mechanism is used for controlling the water flow of the cleaning actuator.

[0039] The cleaning actuator includes sev...

Embodiment 2

[0052] A method for cleaning a converter vaporization cooling flue, using the water knife cleaning system for the converter vaporization cooling flue provided in Example 1 to clean, comprising the following steps:

[0053] S1. Fix the converter vaporization cooling flue, first place the water knife at the initial position, preferably the center position of the flue port, and use this position as the original coordinate point;

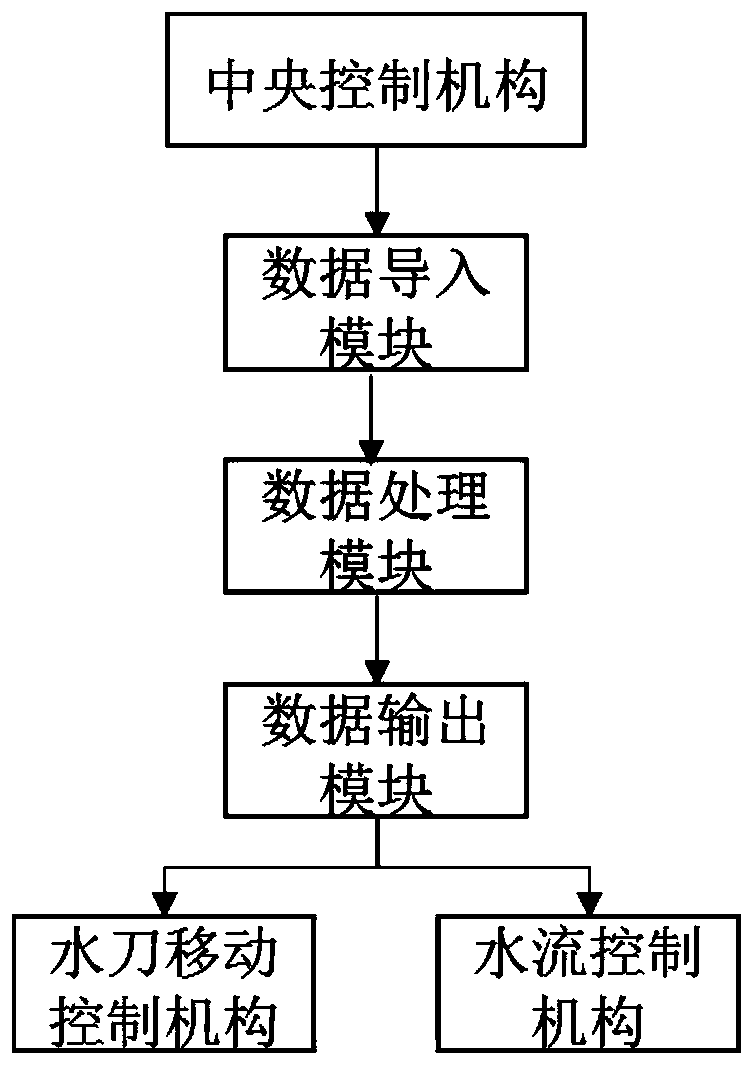

[0054] S2. Input the parameters (diameter, material, thickness, length, etc.) of the converter vaporization cooling flue to the data import module of the central control mechanism, and the data processing module of the central control mechanism obtains the telescopic rod and the rotating rod according to the parameter design Operating parameters and rotary rod and waterjet injection pressure;

[0055] S3. The first motor and the second motor control the movement of the telescopic rod and the rotating rod according to the operating parameters of the tele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com