A hanging galvanizing production line and its production process

A production line and plating production line technology, applied in plating tanks, electrolytic components, electrolytic processes, etc., can solve problems affecting the quality of electroplating processing, pollution, etc., and achieve the effects of improving the quality of electroplating processing, avoiding pollution, and improving the quality of electroplating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

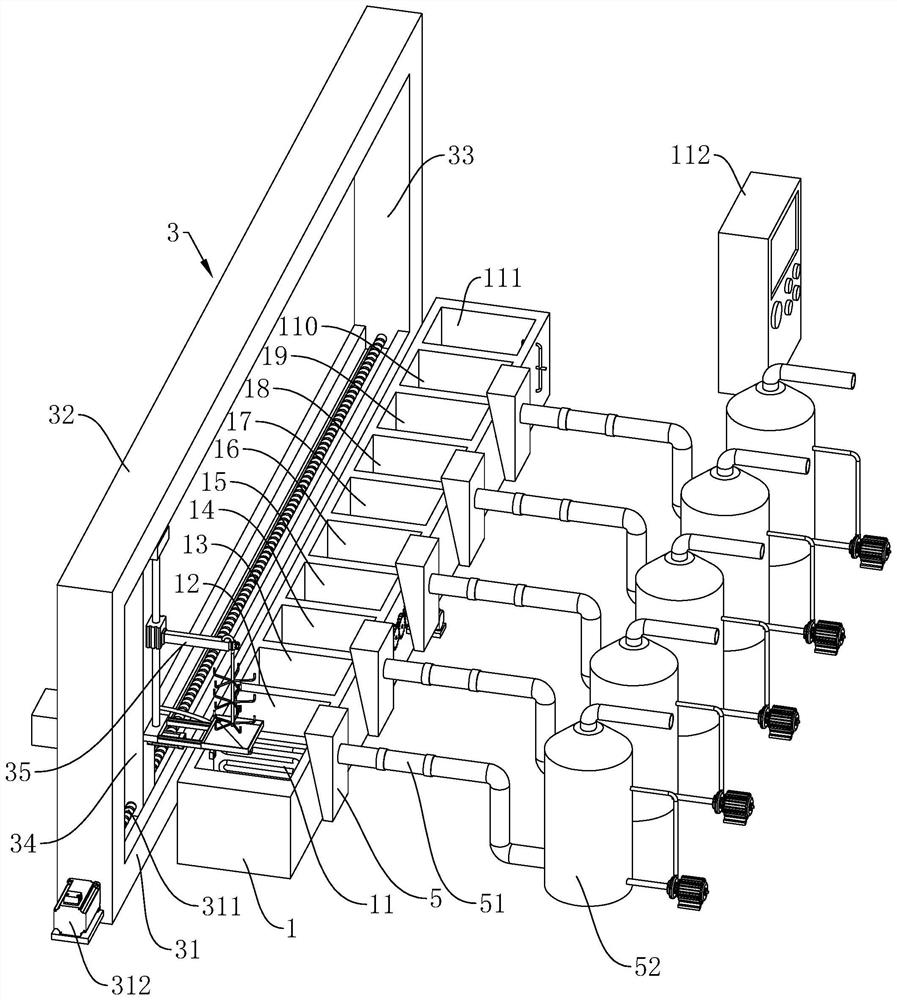

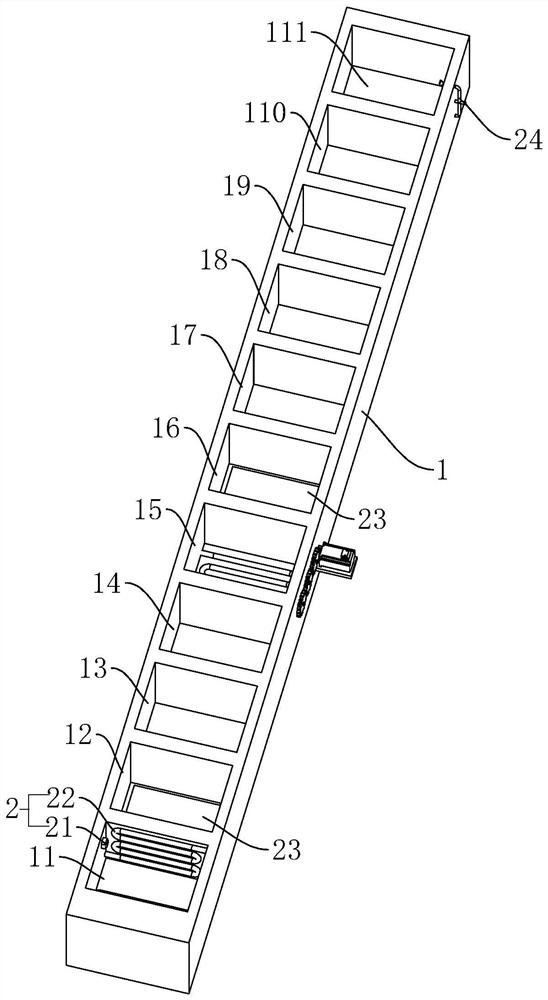

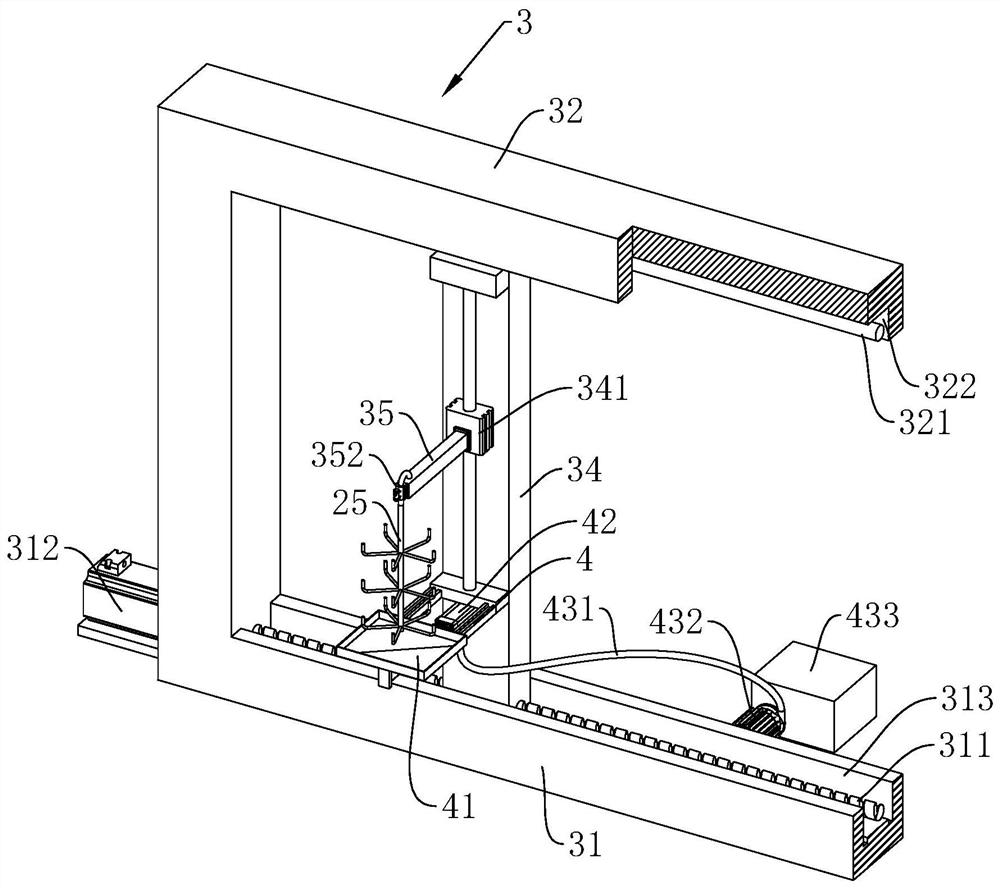

[0051] refer to figure 1 and figure 2 , is a hanging galvanizing production line and its production process disclosed by the present invention, including an electroplating production line 1 for electroplating. The electroplating production line 1 includes a degreasing tank 11, a first washing tank 12, a pickling tank 13, a second washing tank 14, an electroplating tank 15, a third washing tank 16, a light emitting tank 17, and a fourth washing tank arranged in sequence along the horizontal direction. 18. Passivation tank 19, fifth washing tank 110 and drying tank 111. The degreasing tank 11 is filled with a degreasing agent for removing the oil stain on the surface of the workpiece, the pickling tank 13 is filled with an acidic solution for removing the oxide layer on the surface of the workpiece, and the electroplating tank 15 is equipped with electroplating equipment and electroplating solution. 17 is provided with a light-extracting agent for making the surface of the wo...

Embodiment 2

[0060] refer to figure 1 and figure 2 , is a kind of production technology that is applied to a kind of hanging galvanizing production line in embodiment one, comprises the following steps:

[0061] S1, hang up: hang the electroplating hanger 25 with the workpiece on the support beam 35 through the hook hole 351, and buckle the collar 352 on the main rod 251 of the electroplating hanger 25;

[0062] S2. Degreasing: After adding the degreasing agent in the degreasing tank 11, the transport device 3 is controlled by the PLC control cabinet 112 to immerse the electroplating hanger 25 with the workpiece in the degreasing tank 11 to degrease the workpiece. After soaking the electroplating rack 25 in the degreasing tank 11 for 1600-1900s, lift the degreased electroplating rack 25 through the support beam 35;

[0063] The degreasing tank 11 is also provided with a temperature control device 2 that can heat the degreasing agent, so that the degreasing agent is kept at a suitable re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com